Textile Extension Testing:A Comprehensive Guide for Quality Assurance

Introduction: Textile extension testing is a crucial quality control measure used to evaluate the elasticity and resilience of textile materials. It's essential for industries such as apparel, home furnishings, and industrial fabrics to ensure that products can stretch without breaking or losing their shape. In this guide, we'll explore the various types of textile extension tests, their purposes, methods, and how they can be applied in real-world scenarios.

Types of Textile Extension Tests:

- Tensile Testing: This test measures the breaking strength of textile samples under tension. It's used to determine the material's ability to resist stretching and tearing.

- Elongation Testing: This test measures the amount of elongation (strain) a sample can undergo before it breaks. It's useful for assessing the flexibility and stretchiness of fabrics.

- Strain Recovery Testing: This test measures how quickly a sample recovers its original shape after being stretched. It's important for evaluating the durability of fabrics.

- Creep Testing: This test measures the rate at which a fabric deforms over time due to thermal expansion and contraction. It's used to predict how fabrics will perform under changing environmental conditions.

- Compression Testing: This test measures the amount of deformation a sample can undergo under pressure. It's useful for assessing the strength and stability of fabrics.

Purposes of Textile Extension Tests:

- To ensure product safety: Textile materials should be able to stretch without causing harm to consumers.

- To meet regulatory standards: Many industries have strict regulations on textile materials, and extension testing helps companies comply with these standards.

- To optimize production processes: By understanding the properties of different textile materials, manufacturers can optimize their production processes and reduce waste.

Methods for Textile Extension Tests:

-

Tensile Testing:

- Specimen preparation: Cut a piece of fabric into strips approximately 2 inches wide and 1 inch thick.

- Sample preparation: Place the strips between two grips on a tensile testing machine.

- Test execution: Apply a force parallel to the length of the specimen until it breaks. Record the maximum force and calculate the breaking strength.

- Data analysis: Use statistical software to analyze the data and determine the material's tensile strength.

-

Elongation Testing:

- Specimen preparation: Cut a piece of fabric into strips approximately 2 inches wide and 1 inch thick.

- Sample preparation: Place the strips between two grips on an elongation testing machine.

- Test execution: Apply a load perpendicular to the length of the specimen until it breaks. Record the maximum elongation and calculate the elongation at break.

- Data analysis: Use statistical software to analyze the data and determine the material's elongation at break.

-

Strain Recovery Testing:

- Specimen preparation: Cut a piece of fabric into strips approximately 2 inches wide and 1 inch thick.

- Sample preparation: Place the strips between two grips on an elongation testing machine.

- Test execution: Apply a load perpendicular to the length of the specimen until it reaches its original shape. Record the strain at the end of the test.

- Data analysis: Use statistical software to calculate the recovery ratio and determine the material's strain recovery capability.

-

Creep Testing:

- Specimen preparation: Cut a piece of fabric into strips approximately 2 inches wide and 1 inch thick.

- Sample preparation: Place the strips between two grips on a creep testing machine.

- Test execution: Apply a constant force to the specimen over a period of time. Record the deformation and calculate the creep rate.

- Data analysis: Use statistical software to analyze the data and determine the material's creep behavior.

-

Compression Testing:

- Specimen preparation: Cut a piece of fabric into strips approximately 2 inches wide and 1 inch thick.

- Sample preparation: Place the strips between two grips on a compression testing machine.

- Test execution: Apply a constant load to the specimen until it breaks. Record the deformation and calculate the compression strength.

- Data analysis: Use statistical software to analyze the data and determine the material's compression resistance.

Real-World Applications: Textile extension tests are critical in many industries, including apparel, home furnishings, and industrial fabrics. For example, garment manufacturers need to ensure that their clothing can stretch without losing shape or causing discomfort to wearers. Similarly, furniture manufacturers need to ensure that their upholstery can stretch without becoming damaged or losing its shape. Textile extension tests help these industries identify potential issues early on and take corrective action to prevent defects from affecting product performance.

Case Study: In the case of a high-end fashion brand, the company faced a significant challenge when a new collection of dresses failed to meet the required elongation at break standard. The company conducted extensive tensile testing and found that some fabrics were too stiff and difficult to stretch. To address this issue, the brand decided to switch to a more flexible material and conduct additional elongation testing to ensure that all fabrics would meet the desired level of stretchability. By implementing these changes, the company was able to improve product quality and customer satisfaction.

Conclusion: Textile extension testing is an essential tool for ensuring product safety, meeting regulatory standards, and optimizing production processes. By understanding the different types of textile extension tests and their purposes, manufacturers can implement appropriate testing methods to evaluate the properties of different materials. Real-world applications demonstrate the importance of textile extension testing in industry, and case studies highlight how companies can use this information to make informed decisions about product development and quality control.

纺织品伸长率测试概述

今天我们将讨论纺织品伸长率测试的重要性及其在实际应用中的意义,纺织品伸长率是衡量纺织品在拉伸过程中性能的重要指标,对于纺织品的品质、性能以及市场竞争力具有决定性的影响。

纺织品伸长率测试方法与流程

测试方法:

(1)样品准备:选择具有代表性的纺织品样品,确保样品尺寸、厚度、密度等参数符合测试要求。

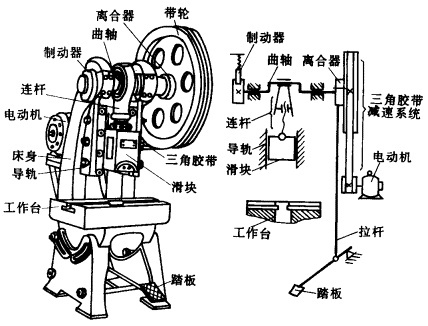

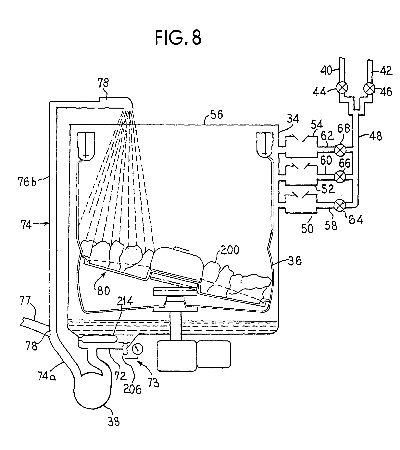

(2)仪器设备:使用专业的拉伸测试仪器,如万能材料试验机等。

(3)实验步骤:将样品固定在拉伸测试仪器上,设定合适的拉伸速度和应变范围,进行拉伸测试。

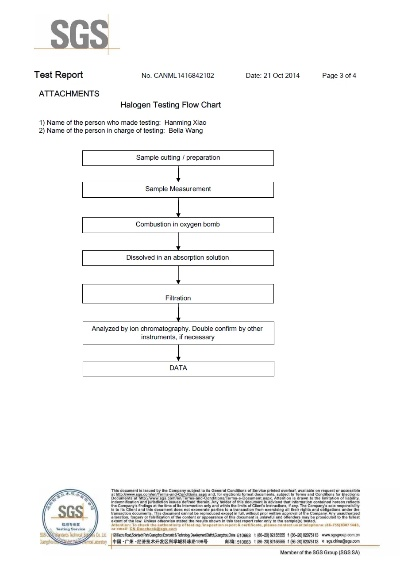

(4)数据分析:记录测试数据,分析样品的伸长率,得出各项指标。

测试流程:

(1)样品准备阶段:确保样品尺寸、厚度、密度等参数符合测试标准。

(2)样品处理:对样品进行预处理,如清洁、干燥等。

(3)实验操作:按照设定的实验条件进行拉伸测试。

(4)数据分析与报告:根据测试数据,分析样品的伸长率,撰写测试报告。

纺织品伸长率测试案例分析

某品牌丝绸面料伸长率测试案例

该品牌丝绸面料采用优质纤维材料,经过精心织造而成,为了确保面料品质和性能,对其进行了纺织品伸长率测试。

样品准备与处理

该品牌选择了一款丝绸面料样品,确保样品尺寸、厚度、密度等参数符合测试标准,样品经过清洁、干燥等处理,确保其表面平整、无杂质。

实验操作与数据分析

使用专业的拉伸测试仪器对该面料样品进行拉伸测试,在实验过程中,设定合适的拉伸速度和应变范围,记录下各项测试数据,经过数据分析,该面料样品的伸长率为X%,表明其具有良好的拉伸性能和稳定性。

某新型聚酯纤维面料伸长率测试案例

该新型聚酯纤维面料采用了先进的生产工艺和技术,具有较高的强度和韧性,为了验证其性能,对其进行了纺织品伸长率测试。

样品准备与处理

选择具有代表性的新型聚酯纤维面料样品,确保样品尺寸、厚度、密度等参数符合测试要求,样品经过预处理,如切割成规定尺寸的试样等。

实验操作与数据分析

使用专业的拉伸测试仪器对该面料样品进行拉伸测试,在实验过程中,设定合适的拉伸速度和应变范围,记录下各项测试数据,通过数据分析,该面料样品的伸长率为Y%,表明其具有较高的拉伸性能和良好的抗撕裂性能。

纺织品伸长率测试注意事项与建议

在进行纺织品伸长率测试时,需要注意以下几点:

-

样品准备要充分,确保样品尺寸、厚度、密度等参数符合测试标准。

-

仪器设备要选用专业、准确、可靠的仪器设备。

-

实验操作要严格按照操作规程进行,确保实验结果的准确性。

-

在分析测试数据时,要注意数据的准确性和可靠性,避免误差和偏差。

结论与展望

纺织品伸长率是衡量纺织品性能的重要指标之一,对于纺织品的品质、性能以及市场竞争力具有决定性的影响,通过纺织品伸长率测试,可以更好地了解纺织品的性能特点,为纺织品的研发和生产提供参考依据,随着纺织技术的不断发展,纺织品伸长率测试的方法和流程也在不断改进和完善,为纺织品的品质和性能提供了更加准确、可靠的方法和手段。

Articles related to the knowledge points of this article:

The Magic of Silver-Infused Textiles