The Industrial Heartbeat of Indias Textile Industry

The textile industry in India is a vital sector, contributing significantly to the country's economy. This sector employs millions of people and generates substantial revenue, making it one of the largest employers in the country. The textile industry has a long history in India, with ancient civilizations such as the Mauryas and the Gupta dynasties being known for their textile production. Today, the industry is diverse, encompassing everything from cotton to silk, and spanning various regions across the country. The growth of the textile industry is driven by several factors, including government policies aimed at promoting domestic production, increased awareness about environmental sustainability, and the growing demand for high-quality clothing and home furnishings. Despite these challenges, the Indian textile industry remains resilient and continues to play an important role in shaping the nation's economic landscape.

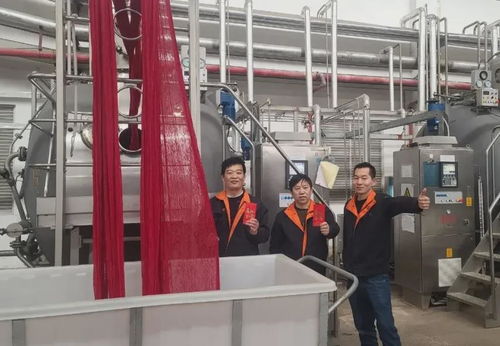

In the bustling metropolis of Mumbai, lies a vibrant nexus of industry that is not just a testament to human ingenuity but also an integral part of India's economy. This heartbeat of the textile industry is akin to the beating of a drum, resounding with the rhythmic thud of machines and the melodic hum of creativity. It is a place where threads weave into fabrics that are not just functional, but also emblematic of Indian identity.

India's textile sector is one of the largest employers in the country, employing millions of people across various stages of production. From raw material procurement to finished product assembly, every step is a testament to the resilience and adaptability of the local workforce. The textile industry in India is characterized by its diversity, from traditional handloom weaving to modern factories producing high-end garments.

The textile industry in India is a microcosm of the nation's cultural heritage and economic progress. Each fabric, each thread, carries with it the stories of generations past, and the hopes and dreams of those who work within its confines.

Let us delve into the complexities of this industry, taking a closer look at some of its key players, processes, and challenges.

Key Players in the Textile Industry

-

Raw Material Suppliers: These are the primary suppliers of raw materials for the textile industry. They play a crucial role in ensuring that the industry has access to quality yarns, fabrics, and other essential components.

-

Manufacturers: These are the companies that manufacture textile products. They use the raw materials provided by the suppliers and transform them into finished products such as shirts, pants, dresses, etc.

-

Exporters: These are the businesses that take manufactured textile products to international markets. They play a vital role in promoting Indian textile products to customers worldwide.

-

Importers: These are the businesses that bring raw materials and finished products back into the country. They help to maintain the balance between supply and demand in the industry.

Processes in the Textile Industry

The textile industry in India operates on a large scale, with several processes involved in the production of textile products. These processes include:

-

Designing: The first step in the textile industry is designing. Designers come up with patterns, designs, and colors that will be used in creating textile products.

-

Preparation: Once the design is finalized, the next step is preparation. This involves preparing the raw materials, such as yarns and fabrics, which will be used to create the desired product.

-

Weaving: Weaving is the most labor-intensive process in the textile industry. It involves interlacing multiple threads to create a woven fabric.

-

Knitting: Knitting is another popular process in the textile industry. It involves looping multiple threads together to create a knitted fabric.

-

Dyeing: Dyeing is a critical process in the textile industry. It involves applying dyes to the fabric to change its color or pattern.

-

Finishing: After the fabric is produced, it needs to be finished before it can be sold. Finishing includes adding labels, tags, and other decorative elements to the product.

-

Packaging: Finally, the finished product is packaged and shipped to retailers or exporters.

Challenges Faced by the Textile Industry

Despite its vast potential, the textile industry in India faces several challenges that need to be addressed if it is to continue growing sustainably. Some of these challenges include:

-

Declining Demand: The decline in global demand for textile products due to increased competition from other industries and changing consumer preferences has put pressure on the industry.

-

Rise in Costs: Higher costs of raw materials and labor have made it difficult for manufacturers to remain competitive.

-

Environmental Pollution: The textile industry is responsible for significant amounts of water and air pollution. Addressing this issue is crucial for the long-term sustainability of the industry.

-

Skilled Labor Shortage: A shortage of skilled workers in the textile industry is hampering its growth. Governments and organizations are working towards addressing this issue through training programs and incentives.

-

Trade Barriers: Trade barriers imposed by countries like China and Pakistan have made it difficult for Indian textile products to reach global markets.

Case Study: Jaipur Textile Mills

Jaipur Textile Mills is a leading manufacturer of high-quality textile products in India. The company was established in 1980 and has since become a symbol of excellence in the Indian textile industry.

The company operates on a large scale, employing thousands of people across various stages of production. Its success can be attributed to several factors, including its commitment to quality, innovation, and sustainability.

One of the key aspects of Jaipur Textile Mills' success is its focus on quality. The company insists on using only high-quality raw materials and employs experienced designers who create unique and stylish patterns. This has helped the company to build a strong brand reputation among consumers.

Another important factor is innovation. Jaipur Textile Mills constantly seeks to improve upon existing techniques and technologies, introducing new processes and equipment that enhance efficiency and productivity. The company's commitment to innovation has allowed it to stay ahead of its competitors and remain relevant in the ever-changing world of textile manufacturing.

Finally, sustainability is a critical aspect of Jaipur Textile Mills' operations. The company is committed to reducing its environmental impact by adopting sustainable practices such as using renewable energy sources and implementing waste management strategies. By prioritizing sustainability, Jaipur Textile Mills has earned the trust and loyalty of consumers and investors alike.

In conclusion, the textile industry in India is a vital component of the country's economy, providing jobs and contributing to its overall development. However, it faces several challenges that need to be addressed if it is to continue growing sustainably. By focusing on quality, innovation, and sustainability, Jaipur Textile Mills has demonstrated how a company can thrive in today's rapidly changing world of textile manufacturing.

大家好,今天我想和大家分享一下我在印度纺织厂工作的经历,印度是一个拥有丰富纺织资源的国家,这里的纺织厂为我们提供了许多就业机会,我不仅学到了很多关于纺织的知识,还结识了许多有趣的人和事。 概述

在纺织厂,我的主要工作内容包括生产、质检、包装和出货等,每天的工作都充满了挑战和机遇,在生产环节,我们需要根据订单安排生产计划,确保按时完成高质量的产品,在质检环节,我们严格把关,确保每件产品都符合质量标准,包装环节则需要我们细心操作,确保产品包装整齐、安全、环保,出货环节更是关键,我们需要与物流公司紧密合作,确保产品能够准时送达客户手中。

具体案例说明

下面我将通过一个具体的案例来说明我在纺织厂的工作情况。

订单处理

有一次,我们接到了一个大型订单,为了确保按时交货,我们全体员工加班加点,全力以赴,在生产过程中,我们遇到了许多困难和挑战,比如原材料供应不稳定、设备故障等,我们凭借团队协作和高效的工作态度,最终成功完成了订单,这不仅提高了我们的工作效率,也让我们更加了解了团队合作的重要性。

产品质量控制

在质量控制环节,我们非常注重产品的质量,我们有一套严格的质量检测流程,从原材料验收到成品出厂都有专人负责,我们还定期进行质量检查和抽检,确保每件产品都符合质量标准,有一次,我们发现一批次产品存在一些质量问题,但是我们迅速采取了措施,加强了质量控制力度,最终成功避免了批量退货的情况发生,这让我们更加明白了质量控制的必要性和重要性。 中的具体细节说明

在纺织厂的工作中,我们还需要注意一些具体细节,在生产过程中需要严格遵守安全操作规程,确保生产安全;在包装环节需要细心操作,避免产品破损或污染;在与客户沟通时需要耐心细致,确保客户的需求得到满足等等。

工作体验总结

在纺织厂工作让我深刻体会到了工作的艰辛与乐趣,我不仅学到了许多关于纺织的知识和技能,还结识了许多有趣的人和事,我也明白了团队合作的重要性以及质量控制的必要性和重要性,我相信,只要我们坚持不懈地努力工作,就一定能够取得更好的成绩。

印度纺织厂的工作体验让我受益匪浅,我不仅学到了许多关于纺织的知识和技能,还结识了许多有趣的人和事,我相信,只要我们继续努力工作,就一定能够取得更好的成绩,我也希望更多的人能够来到这里工作和学习,共同推动纺织行业的发展。

Articles related to the knowledge points of this article:

The Role of Textile Factory Womens Teachers

The Hidden Traps of Textile Mills:An Unveiling of Pollution Emissions

The Ghazni Textile Factory:An Insight into the World of Textile Manufacturing