Navigating the Challenges of Textile Mill Circuit Wiring

"Navigating the Challenges of Textile Mill Circuit Wiring",Textile mills are essential industrial hubs for producing textile materials, but their circuit wiring poses significant challenges. These challenges include high electrical loads, frequent maintenance, and the need to ensure safe operations. To overcome these challenges, textile mills must implement advanced electrical systems that can handle heavy loads and provide reliable power supply. These systems should also be designed with safety in mind, including overload protection, grounding, and proper wiring practices. Additionally, regular maintenance and inspections are crucial to detect and address potential issues before they become major problems. By adopting these strategies, textile mills can improve their efficiency, reduce downtime, and ensure a safer work environment for their employees.

Introduction: In the world of textile manufacturing, every detail counts. From the intricate weaving process to the efficient operation of machinery, a well-designed electrical system is essential for ensuring the seamless functioning of the entire facility. One crucial aspect of this system is the wiring of the electrical circuits within the textile mill. However, with its complexity and potential for errors, it can be a daunting task. In this guide, we will explore the intricacies of textile mill circuit wiring, highlighting some common challenges and providing practical solutions.

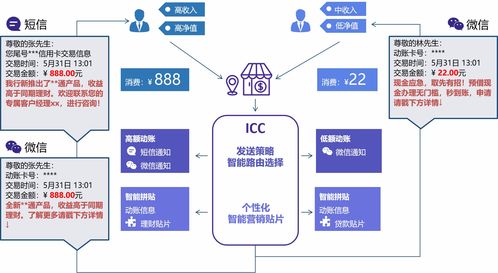

Circuit Diagram: To begin with, let's take a look at a simple circuit diagram for a typical textile mill. This diagram should include all the components such as switches, relays, sensors, and motors that are connected to each other through wires. It's important to note that the actual layout may vary depending on the specific needs of the textile mill.

Table: Here's an example of a table that summarizes some of the key points mentioned above: | Component | Function | Connection Type | |----------|----------|-----------------| | Switches | Enable/disable circuits | Circuit Breakers | | Relays | Control the flow of current | Relays | | Sensors | Monitor temperature, humidity, etc. | Resistors, Diodes | | Motors | Drive machinery | Motors |

Common Challenges:

-

Overloading: One of the most significant challenges in textile mill circuit wiring is overloading. This occurs when too many devices are connected to a single circuit, leading to excessive current draw and potential damage to the wiring. To prevent this, it's important to ensure that each device has its own dedicated circuit and that there is adequate capacity to handle the load.

-

Short Circuits: Short circuits can occur when two or more wires come into contact with each other. This can cause a fire or explosion and is a serious safety hazard. To avoid this, it's essential to use appropriate connectors and grounding techniques to minimize the risk of short circuits.

-

Faulty Installation: Another common issue is faulty installation. This can result from improper soldering, incorrect wiring methods, or inadequate testing before final assembly. To mitigate these risks, it's crucial to follow strict guidelines for installation and testing, and to have experienced personnel conducting the work.

-

Poor Maintenance: Lack of maintenance can also lead to problems with textile mill circuit wiring. Over time, insulation may degrade, causing wear and tear on the wiring, and reducing its lifespan. Regular inspections and cleaning can help identify and address these issues early on.

Case Study: One example of a successful textile mill circuit wiring project is the installation of a new electrical system at a major garment factory in New York City. The factory had been experiencing frequent power outages due to faulty wiring, which was affecting production efficiency and worker safety. The electrical team hired a reputable local company to perform a thorough inspection of the existing wiring and identified several areas where improvements were needed. They then developed a comprehensive plan to replace old wiring with modern, energy-efficient cables and install new circuit breakers and fuses. The team also conducted thorough testing before final assembly, ensuring that all components were securely connected and that the system was functioning properly. After the installation, the factory experienced significant improvement in power reliability and reduced downtime, resulting in increased productivity and improved worker safety.

Conclusion: The success of textile mill circuit wiring projects depends heavily on careful planning, attention to detail, and adherence to best practices. By understanding the challenges involved and implementing effective solutions, textile mills can optimize their electrical systems and achieve maximum efficiency and safety. Remember, investing in quality electrical infrastructure is not only beneficial for today's operations but also ensures long-term sustainability and investment returns.

大家好,今天我们将探讨纺织厂电路布线的相关话题,纺织厂在生产过程中,电路布线的重要性不言而喻,良好的布线系统不仅可以确保生产过程的稳定性和安全性,还能提高工作效率和降低维护成本,下面我们将通过一个案例分析,详细介绍纺织厂电路布线的要点。

纺织厂电路布线现状分析

在纺织厂中,电路布线通常涉及多个方面,包括电源线路、信号线路、控制线路等,为了确保布线系统的稳定性和可靠性,纺织厂通常会采取一系列措施来确保布线质量,采用高质量的绝缘材料、选用合适的导线规格和颜色、遵循安全规范等。

案例说明

以下是一个纺织厂电路布线的案例分析:

某纺织厂电路布线改进方案

该纺织厂在电路布线方面采用了先进的布线技术和严格的安全规范,该厂对现有的电源线路和信号线路进行了全面的检查和评估,确定了需要优化的区域,该厂采用了高质量的绝缘材料和符合安全标准的导线规格和颜色,该厂还采用了智能化的布线管理系统,实现了对布线过程的实时监控和优化。

布线过程中的注意事项

在布线过程中,纺织厂需要注意以下几点:

- 选择合适的导线规格和颜色:根据电路的功能和安全要求,选择符合要求的导线规格和颜色。

- 遵循安全规范:在布线过程中,必须遵守相关的安全规范和标准,确保布线系统的安全性和可靠性。

- 考虑环境因素:在布线过程中,需要考虑环境因素,如温度、湿度等因素对导线性能的影响。

纺织厂电路布线的要点

- 布线设计:根据电路的功能和安全要求,设计合理的布线方案,需要考虑电源线路、信号线路和控制线路的布局和连接方式。

- 绝缘材料选择:选用高质量的绝缘材料,确保布线系统的绝缘性能。

- 导线连接:导线连接必须牢固可靠,避免出现接触不良或短路等问题,可以采用焊接、压接等方式进行连接。

- 布线管理:采用智能化布线管理系统,实现对布线过程的实时监控和优化,可以包括数据采集、数据分析、报警提示等功能。

- 安全防护:在布线过程中,必须遵守相关的安全规范和标准,确保布线系统的安全性和可靠性,还需要采取相应的安全防护措施,如防火、防电击等。

英文案例说明(表格形式)

以下是一个纺织厂电路布线的英文案例说明表格:

| 项目 | 描述 | 说明 |

|---|---|---|

| 布线现状 | 纺织厂现有电路布线情况 | 该纺织厂现有电路布局复杂,涉及电源线路、信号线路和控制线路等多个方面 |

| 布线改进方案 | 改进措施 | 采用先进的布线技术和严格的安全规范,对电源线路和信号线路进行优化 |

| 布线设计 | 布线方案 | 根据电路的功能和安全要求,设计合理的布局和连接方式 |

| 绝缘材料选择 | 材料选择 | 选择高质量的绝缘材料,确保布线系统的绝缘性能 |

| 导线连接 | 方法选择 | 采用焊接、压接等方式进行导线连接 |

| 布线管理 | 管理手段 | 采用智能化布线管理系统,实现对布线过程的实时监控和优化 |

| 安全防护措施 | 安全防护要求 | 遵守相关的安全规范和标准,采取相应的安全防护措施,如防火、防电击等 |

| 安全案例分析 | 安全案例一(某纺织厂) | 该纺织厂在电路布线方面采用了先进的布线和严格的安全规范,实现了良好的布线效果和安全性能 |

| 安全案例分析数据 | 数据指标 | 如导线连接牢固可靠、安全防护措施到位等指标数据 |

纺织厂电路布线的关键在于设计合理的布线方案、选用高质量的绝缘材料、采取可靠的导线连接方式以及实施严格的安全防护措施,通过采用先进的布线和安全规范以及智能化管理手段,可以确保纺织厂电路布线的稳定性和可靠性,提高生产效率和降低维护成本。

Articles related to the knowledge points of this article:

The Evolution of Tianzhuang East Textile Factory

The Dynamics of the Huahai Textile Factory:A Tale of Success and Innovation