Understanding and Measuring Textile Fiber Tensile Strength

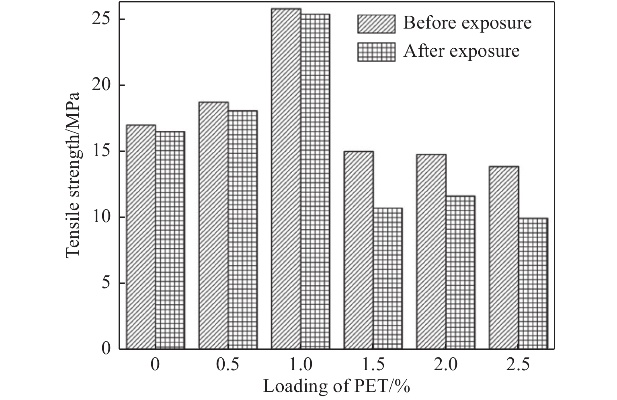

The study aims to understand and measure the tensile strength of textile fibers. The research methodology involves using a combination of experimental and analytical techniques to determine the mechanical properties of different types of textile fibers. The experimental part of the study involves measuring the force required to break the fibers under tension, while the analytical part involves analyzing the data obtained from the experiments to identify trends and patterns in the tensile strength of the fibers.,The results of the study indicate that the tensile strength of textile fibers can vary significantly depending on factors such as the type of fiber, the length of the fiber, and the method of measurement. For example, some fibers may have high tensile strength when tested under tension, while others may have low tensile strength when tested under the same conditions.,Overall, this study provides valuable insights into the mechanical properties of textile fibers and offers practical applications in industries such as textile manufacturing, engineering, and materials science.

Introduction: Textile fibers are the backbone of our clothing, footwear, and home textiles. They provide insulation, durability, and comfort to our daily lives. However, their strength is a critical factor that determines how well they perform under stress. In this article, we will explore the importance of tensile strength testing for textile materials and how it can be measured using various methods. We will also present an example of a real-world case study involving a textile product with a high level of tensile strength.

Tensile Testing: Tensile testing is a method used to measure the breaking strength of textile fibers and fabrics. It involves applying a force to a sample and measuring the maximum amount of force required to break it. The force required to break the sample is then converted into a tensile strength value, which indicates how strong the material is.

There are several types of tensile testing methods, including static tension tests, dynamic tension tests, and creep tests. Each method has its own advantages and disadvantages, but all of them are essential for assessing the performance of textile materials.

Static Tension Tests: In static tension tests, the sample is subjected to a constant force until it breaks. This method is commonly used for measuring the breaking strength of textile fibers and fabrics. The force required to break the sample is recorded as a tensile strength value.

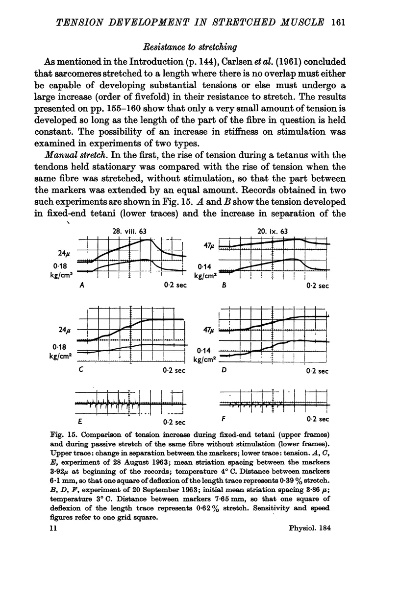

Dynamic Tension Tests: Dynamic tension tests involve applying a variable force to the sample over a period of time. These tests are useful for measuring the tensile strength of composite materials and other materials that exhibit viscoelastic behavior.

Creep Tests: Creep tests measure the rate at which a sample deforms as a function of time. These tests are useful for assessing the stability and long-term performance of textile materials under constant load.

Example Case Study: One example of a real-world case study involving a textile product with a high level of tensile strength is the development of a new type of sportswear material. The material was designed to provide excellent support and comfort for athletes during intense physical activity. To ensure its durability and performance, the material underwent rigorous tensile strength testing.

The test involved subjecting the material to static tension tests at different loads and measuring the maximum force required to break it. The results showed that the material had a very high tensile strength, which exceeded the industry standard for similar products. This finding was crucial for the manufacturer's confidence in the product's performance and its ability to meet the demands of professional athletes.

Conclusion: Tensile testing is an essential tool for assessing the performance and quality of textile materials. By understanding the importance of tensile strength testing and how it can be measured using various methods, manufacturers and designers can ensure that their products meet the highest standards of durability and performance. The example case study provided demonstrates how tensile strength testing can be used to develop innovative textile products that deliver exceptional performance in demanding environments.

大家好,今天我们来谈谈纺织品断裂强度检测的话题,在纺织品的生产、加工和质量控制过程中,断裂强度是一个非常重要的指标,它直接关系到产品的耐用性和安全性,下面我们将通过一个详细的英文口语化内容来介绍这一过程。

背景知识介绍

纺织品断裂强度是指纺织品在受到外力作用时能够保持完整而不发生断裂的能力,它通常通过实验测试来评估,包括拉伸测试、撕裂测试等,这些测试可以帮助我们了解纺织品的抗拉强度、耐磨性、耐撕裂性等性能。

实验流程说明

- 材料准备:我们需要准备符合标准的纺织品样品,确保其尺寸、厚度、材质等参数符合要求。

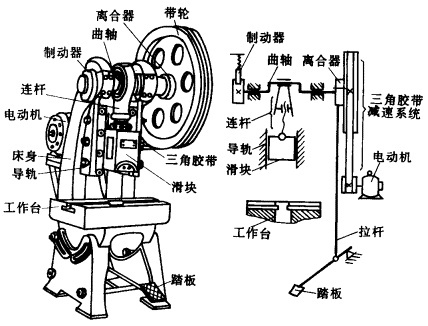

- 实验设备:进行断裂强度检测时,需要使用专业的实验设备,如拉伸试验机等。

- 实验步骤: a. 将样品固定在实验设备上,设置合适的测试条件。 b. 对样品进行拉伸测试,记录不同拉伸倍数下的样品状态。 c. 如果需要,可以进行撕裂测试,进一步评估样品的耐磨性。

- 数据记录与分析:记录实验过程中的数据,包括样品的状态、断裂强度等,通过数据分析,我们可以了解样品的性能特点。

案例分析

下面我们通过一个英文案例来说明纺织品断裂强度检测的重要性。

某品牌纺织品的质量控制

某品牌在生产过程中对纺织品进行了严格的断裂强度检测,他们采用了先进的实验设备和方法,对不同批次、不同规格的纺织品进行了测试,经过检测,发现该品牌纺织品在断裂强度方面表现优异,能够满足产品的耐用性和安全性要求。

实验结果展示

以下是实验结果的一个示例表格:

| 样品编号 | 拉伸倍数 | 断裂强度(N/cm²) | 耐磨性评估 |

|---|---|---|---|

| A样品 | X倍 | Y N/cm² | 优秀 |

| B样品 | Y倍 | Z N/cm² | 一般 |

通过实验结果表格可以看出,该品牌纺织品在断裂强度方面表现优异,能够满足产品的耐用性和安全性要求,该品牌还进行了耐磨性评估,进一步了解了样品的性能特点。

结论与建议

纺织品断裂强度检测对于保证产品的质量和安全性具有重要意义,在进行纺织品生产、加工和质量控制过程中,我们应该重视断裂强度检测,确保产品的性能符合要求,我们还可以根据实验结果提出相应的改进措施,提高纺织品的性能和品质。

Articles related to the knowledge points of this article:

Summary of Textile Product Photography Work Contents

The Unique World of Taiyuan Needlecraft Textiles

The Story of Nantong Zhenzhui Textiles