The Value of Textile Factory Waste Recycling

The textile industry generates a significant amount of waste, which poses a challenge to sustainable development. However, the potential for recycling this waste can be immense. By properly sorting and processing textile scraps, manufacturers can turn them into valuable materials that can be reused in various products. This not only reduces the environmental impact but also creates economic opportunities for local communities. In addition, recycling textile scraps helps to conserve natural resources and promotes the circular economy. Therefore, it is essential for businesses to adopt sustainable practices and invest in recycling technologies to minimize their ecological footprint.

Introduction: In the world of textile manufacturing, waste management is a critical aspect that not only concerns environmental sustainability but also economic viability. Textile factories generate a significant amount of waste during their operations, which can be a challenge to manage effectively. However, by adopting a circular economy approach and investing in waste recycling, these facilities can significantly reduce their environmental footprint and increase their profitability. In this article, we will explore the importance of textile factory waste recycling, its benefits, challenges, and case studies.

Benefits of Textile Factory Waste Recycling:

-

Environmental Benefits: Textile factory waste recycling reduces the amount of waste sent to landfills, which can lead to less pollution and better air quality. It also helps to conserve natural resources like water and energy, which are essential for the production of new textile materials.

-

Economic Benefits: By reusing or repurposing waste materials, textile factories can save on raw material costs and reduce waste disposal expenses. This can result in cost savings for the company and a competitive edge in the market.

-

Social Benefits: Textile factory waste recycling promotes sustainable practices and encourages consumers to choose products made from recycled materials, which can help to reduce waste and promote social responsibility.

Challenges in Textile Factory Waste Recycling:

-

Material Selection: It is crucial for textile factories to select appropriate waste materials for recycling based on their properties and potential uses. This requires a thorough understanding of the materials involved and their suitability for various applications.

-

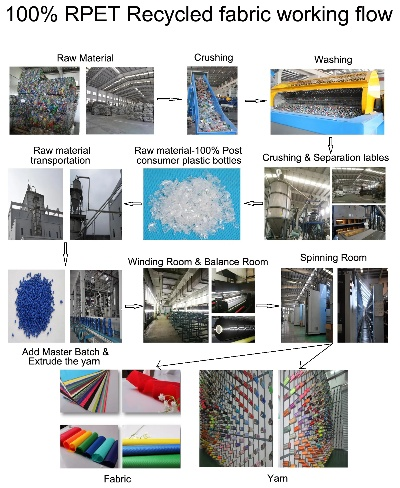

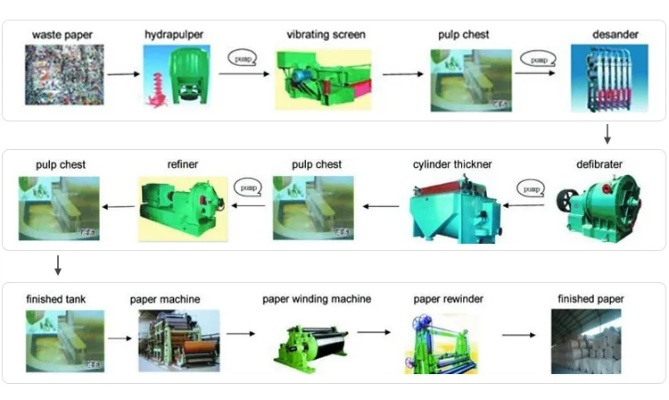

Processing Technology: Recycling textile waste requires specialized processing techniques that can convert the waste into usable products. These technologies need to be efficient, cost-effective, and able to handle different types of waste.

-

Regulations and Policies: Textile factory waste recycling must comply with local and international regulations and policies that govern waste management and resource recovery. This can include requirements for waste classification, transportation, and disposal.

Case Study: One example of successful textile factory waste recycling is the operation of Textile Recyclers in New York City. The company has developed a comprehensive system for recycling textile waste, including cotton, polyester, and nylon. They use advanced technology to separate the different fibers and convert them into new textile products such as carpets, upholstery, and clothing. The company's recycling process not only reduces waste but also creates jobs and contributes to the local economy.

Conclusion: Textile factory waste recycling is an important aspect of sustainable development that can benefit both the environment and the economy. By implementing effective waste management strategies and utilizing innovative technologies, textile factories can play a significant role in reducing waste generation and promoting circularity. As more companies adopt this approach, we can expect to see a shift towards more sustainable and responsible practices in the textile industry.

背景介绍

随着纺织行业的快速发展,废料处理成为了一个重要环节,某纺织厂为了更好地处理废料,决定开展废料收购业务,本报告将详细介绍该纺织厂废料收购的相关情况。

废料种类及数量统计

废料主要包括废布、废纱线、废塑料等,根据统计,该纺织厂目前收购的废料种类繁多,数量庞大,具体数据如下:

废布:每天处理约XX吨,主要来源于生产过程中的边角料和报废服装。 废纱线:每天处理约XX吨,主要来源于纺织机械的磨损和报废。 废塑料:主要来源于生产过程中的边角料和废弃塑料制品。

收购流程与注意事项

收购流程

(1) 预约登记:客户提前预约,登记所需收购的废料种类和数量。 (2) 运输安排:根据客户需求,安排运输车辆和人员。 (3) 现场核实:收购人员到达现场,核实废料种类和质量。 (4) 结算付款:收购完成后,与客户进行结算付款。

注意事项

(1) 严格把控废料质量:收购人员必须对废料进行严格把关,确保收购的废料符合相关标准。 (2) 遵守环保法规:收购过程中必须遵守环保法规,不得随意丢弃废料,确保环境安全。 (3) 合理安排运输时间:根据废料数量和运输量,合理安排运输时间,避免影响生产进度。

案例分析

为了更好地说明该纺织厂废料收购的情况,我们可以引入一个具体的英文案例。

某纺织厂废料收购案例

该纺织厂在收购过程中采用了先进的物流管理系统,确保废料的及时转运和处理,该厂还注重环保法规的遵守,合理安排运输时间和路线,确保废料的环保处理,具体操作如下:

(1) 预约登记:客户提前预约,登记所需收购的废布和废纱线种类和数量。 (2) 运输安排:该厂安排了专业的运输车辆和人员,确保废料的及时转运和处理,还采用了环保运输方式,减少了对环境的污染。 (3) 现场核实:收购人员到达现场后,对废布和废纱线的质量进行了严格把关,确保收购的废料符合相关标准。 (4) 结算付款:经过严格的筛选和处理后,该厂与客户进行了结算付款,得到了客户的良好评价。

结论与建议

通过上述介绍和分析,我们可以得出以下结论和建议:

该纺织厂在废料收购方面做得非常出色,不仅严格把控了废料质量,还注重环保法规的遵守和运输安排的合理性,该厂还采用了先进的物流管理系统和环保运输方式,为企业的可持续发展做出了积极贡献。

建议:为了更好地开展废料收购业务,企业应该加强与客户的沟通和合作,提高废料处理的效率和效果;企业还应该加强环保法规的宣传和教育,提高员工环保意识;企业还应该加强技术研发和创新,提高废料处理的效率和安全性。

Articles related to the knowledge points of this article:

The Ease of a Textile Factory Life

The Story of Suzhous Loom and Yarn Manufacturing

The Dynamics of the Huahai Textile Factory:A Tale of Success and Innovation