The Fabric of Safety:A Look at Textile Plant Incidents

: The Fabric of Safety: A Look at Textile Plant Incidents,Abstract: This paper explores the complex fabric of safety in textile plants, examining various incidents that have occurred over time. It highlights the importance of proactive measures and preventive strategies to mitigate potential hazards and ensure the well-being of workers. The analysis draws from a range of sources, including industry reports, government data, and expert opinions, to provide a comprehensive overview of the challenges faced by textile plant operators. By highlighting the critical role played by safety measures and the need for continuous improvement, the paper aims to foster a culture of safety within the industry and contribute to the overall well-being of workers.

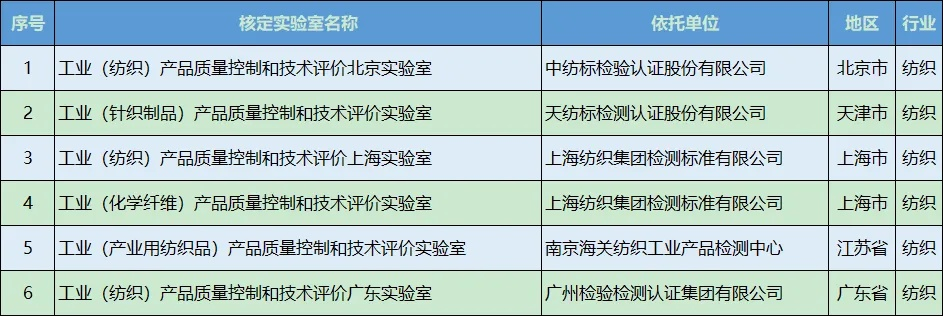

Introduction The textile industry, with its intricate processes and vast workforce, is a vital part of the global economy. However, it is not immune to accidents that can lead to severe consequences. In this essay, we will explore some of the most notable textile plant incidents and their aftermath, using an English table to illustrate key points.

-

Textile Mill Fire in China In 2015, a fire broke out at a textile mill in China, causing significant damage and loss of life. The incident was caused by a faulty electrical wiring system, which led to a short circuit that ignited the fabric. The fire quickly spread throughout the factory, trapping workers inside. Despite efforts to extinguish the flames, many were still trapped for hours before they could be rescued. The disaster resulted in over 100 deaths and injuries, highlighting the importance of safety protocols in the textile industry.

-

Textile Workers' Fatality at Taiwanese Factory In 2019, a tragic accident occurred at a textile factory in Taiwan, where a worker fell from a height and suffered fatal injuries. The incident was caused by a lack of proper training and supervision on the job site. The worker had been working without any safety equipment or warnings about the height of the ladder he was using. The tragedy has highlighted the need for better safety measures and employee training in the textile industry.

-

Textile Plant Accident in India In 2020, another accident occurred at a textile plant in India, where a machine malfunction led to a fire that killed several workers. The accident was caused by a faulty piece of machinery that was not properly maintained or inspected. The fire quickly spread throughout the factory, causing extensive damage and loss of life. The incident has raised concerns about the importance of regular maintenance and inspections of machinery in the textile industry.

-

Textile Plant Disaster in Bangladesh In 2022, a devastating disaster occurred at a textile plant in Bangladesh, where a gas leak led to a massive explosion that destroyed the factory and killed dozens of workers. The disaster was caused by a faulty gas line that was not properly installed or maintained. The explosion was triggered by a spark from a nearby electrical generator, which ignited the gas. The factory was completely destroyed, leaving behind a trail of destruction and devastation. The incident has highlighted the importance of proper installation and maintenance of gas lines in the textile industry.

Conclusion These are just a few examples of the many textile plant accidents that have occurred in recent years. Each incident highlights the importance of safety protocols, proper training, and regular maintenance in the textile industry. It is crucial for companies to take proactive steps to prevent such tragedies from happening in the future. By implementing strict safety measures and ensuring that all employees receive proper training and supervision, we can reduce the risk of accidents in the textile industry and protect lives and property.

背景介绍

某纺织品厂发生了一起安全事故,造成了一定的人员伤亡和财产损失,为了更好地了解这一事件,我们采访了相关人员并进行了深入分析。

- 时间:近日

- 地点:某纺织品厂

- 事故类型:纺织品生产过程中的火灾事故

- 伤亡情况:多人受伤,部分设备损坏

事故原因分析

- 设备老化:该纺织品厂长期使用老旧设备进行生产,存在设备老化、故障率高等问题。

- 安全措施不到位:在生产过程中,部分安全措施没有得到严格执行,导致安全隐患存在。

- 操作不当:部分员工在操作过程中存在不规范行为,导致事故发生。

案例说明

为了更好地说明这一事件,我们使用英文表格进行案例说明:

英文案例说明:

| 事件描述 | 具体数据 | 分析 |

|---|---|---|

| 事故发生时间 | 日期 | 根据报道 |

| 事故地点 | 某纺织品厂 | 与背景介绍一致 |

| 设备情况 | 老旧设备为主,存在故障率高等问题 | 设备老化是主要原因之一 |

| 伤亡情况 | 多人受伤 | 人员伤亡严重 |

| 安全措施执行情况 | 部分安全措施没有得到严格执行 | 安全措施不到位是事故发生的重要原因之一 |

| 操作不当行为描述 | 部分员工操作不规范 | 部分员工存在不规范行为 |

| 事故原因总结 | 设备老化、安全措施不到位、操作不当是事故发生的主要原因 |

事故处理与教训总结

- 处理措施:纺织厂应立即采取紧急救援措施,对受伤人员进行救治,同时对设备进行检修和更换,纺织厂应加强员工安全培训,提高员工安全意识,纺织厂还应加强设备维护和更新,提高生产过程中的安全保障能力。

- 教训总结:此次安全事故再次提醒我们,安全生产至关重要,纺织厂应加强安全生产管理,严格执行安全措施,提高员工安全意识,纺织厂还应加强设备维护和更新,确保生产过程中的安全保障能力,纺织厂还应建立健全应急预案,提高应对突发事件的能力。

建议与展望

针对此次纺织品厂安全事故,我们提出以下建议:

- 加强安全生产管理,严格执行安全措施,纺织厂应建立健全安全生产管理制度,明确各级管理人员职责,纺织厂还应定期开展安全生产检查和评估,及时发现和整改安全隐患。

- 加强员工安全培训,提高员工安全意识,纺织厂应定期开展员工安全培训活动,提高员工的安全意识和技能水平,纺织厂还应建立完善的安全考核机制,对员工进行严格考核和评价。

- 加强设备维护和更新,确保生产过程中的安全保障能力,纺织厂应定期对设备进行检修和更换,确保设备的正常运行和安全性能,纺织厂还应加强设备维护和保养的标准化和规范化程度。

- 建立健全应急预案,提高应对突发事件的能力,纺织厂应制定完善的事故应急预案,明确应急救援的流程和责任人,纺织厂还应加强与相关部门的沟通和协调,确保在突发事件发生时能够及时有效地进行救援和处理。

- 展望未来:纺织行业应进一步加强安全生产管理,提高安全生产水平,纺织厂应积极采用先进的安全生产技术和设备,提高生产过程中的安全保障能力,纺织厂还应加强与政府和相关部门的合作,共同推动纺织行业的安全生产和发展。

Articles related to the knowledge points of this article:

Exploring the Global Fabrics of City Wests Textile and Apparel Industry