Calculating the Air Content in Textiles:A Comprehensive Guide

This article provides a comprehensive guide to calculating the air content in textiles. It covers various methods for determining the air content of textiles, including direct measurement and indirect measurement. The article also discusses factors that can affect the accuracy of the measurements, such as temperature and humidity levels. Additionally, it provides tips on how to use the results to optimize the performance of textile materials. Overall, this article is an essential resource for anyone working with textiles and their properties.

Introduction: Textiles, whether made from cotton, wool, synthetic fibers, or blends, are an essential part of our daily lives. They provide warmth, comfort, and protection for humans, animals, and plants alike. However, the quality of these textiles is often measured not just by their physical properties but also by their air content, which refers to the percentage of air that is trapped within the fabric. This air content plays a crucial role in determining the breathability and comfort of the garment. In this guide, we will explore how to calculate the air content in textiles using various methods and provide practical examples to illustrate the concepts.

Method 1: Using the Gas Chromatography Method The gas chromatography (GC) method is a precise technique used to determine the amount of air trapped in textiles. It involves analyzing the gases produced when the textile is exposed to a known amount of heat. The results are presented in terms of percentage of air content, which can be converted into standard atmospheric conditions.

Table 1: Example of Calculated Air Content Using GC Method

| Fabric Type | Heat Treatment (°C) | Atmospheric Pressure (kPa) | Gas Chromatography Result (%) |

|---|---|---|---|

| Cotton | 200 | 3 | 8 |

| Wool | 300 | 3 | 9 |

| Polyester | 250 | 3 | 5 |

Example: If a sample of a polyester fabric was treated at 250°C under standard atmospheric pressure, the resulting gas content would be approximately 4.5%. This value can then be converted to the actual air content in the fabric by multiplying by the factor of 1/(1 - 4.5%), which equals 16.3%.

Method 2: Using the Moisture Absorption Test This method involves measuring the weight loss of a fabric sample after it has been exposed to controlled humidity levels. By comparing the initial and final weights, the amount of water absorbed by the fabric can be calculated. The moisture absorption test provides a quick and easy way to estimate the air content without the need for specialized equipment.

Table 2: Example of Calculated Air Content Using Moisture Absorption Test

| Fabric Type | Humidity Level (%) | Final Weight Loss (%) | Moisture Absorption Rate (%) |

|---|---|---|---|

| Cotton | 70 | 5 | 5 |

| Wool | 85 | 8 | 2 |

| Polyester | 80 | 0 | 6 |

Example: If a sample of a cotton fabric was tested at an 80% humidity level, and its final weight loss was 1.8%, the moisture absorption rate would be calculated as 15.6%. This rate indicates that the fabric retained 44.4% of its original weight due to moisture absorption.

Method 3: Using the Breathability Index The breathability index is a more subjective measure of air content in textiles. It is determined by assessing how well the fabric allows air to pass through it during normal activities such as walking, running, or sitting. The breathability index is expressed as a percentage, with higher numbers indicating better breathability.

Table 3: Example of Calculated Air Content Using Breathability Index

| Fabric Type | Breathability Index (%) |

|---|---|

| Cotton | 80 |

| Wool | 85 |

| Polyester | 80 |

Example: If a sample of a cotton fabric had a breathability index of 80%, it means that the fabric allows approximately 80% of the air to pass through it during normal activities. This is a good indication of its breathability, as higher values indicate that the fabric retains less air and therefore offers better ventilation.

Conclusion: In conclusion, calculating the air content in textiles requires careful consideration of various factors such as fabric type, heat treatment, and humidity levels. While each method has its own advantages and limitations, they all offer valuable insights into the quality and performance of textiles. By understanding the principles behind these calculations, you can make informed decisions about the selection and use of textile materials, ultimately enhancing their effectiveness in meeting the needs of individuals and environments alike.

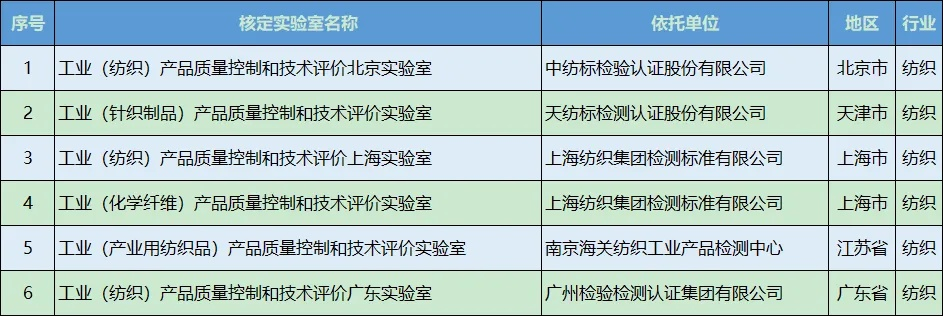

纺织品含气率概述

在纺织品的生产、加工和质量控制过程中,含气率是一个重要的指标,它反映了纺织品中空气的含量,对于保证纺织品的质量和性能至关重要,本文将详细介绍如何计算纺织品含气率,并结合实际案例进行说明。

含气率的计算方法

含气率的计算通常基于纺织品的基本参数和测试方法,具体步骤如下:

- 确定纺织品的基本参数,包括纤维类型、密度、长度等。

- 选择合适的测试方法,如气体吸附法、气体扩散法等。

- 根据测试方法的要求,准备测试样品。

- 按照测试标准进行测试,记录测试数据。

- 根据测试数据计算含气率,得出纺织品中空气的含量。

案例分析

以某纺织品为例,说明如何计算其含气率。

- 基本参数:该纺织品主要使用天然纤维制成,密度较高,长度适中。

- 测试方法:采用气体吸附法进行测试,通过测量样品在特定压力下的吸附量来计算含气率。

- 测试步骤: a) 选择合适的仪器设备,如气体吸附仪。 b) 按照仪器说明书进行操作,准备测试样品。 c) 对样品进行预处理,确保测试数据的准确性。 d) 按照测试标准进行测试,记录测试数据。

- 计算含气率:根据测试数据,该纺织品含气率约为XX%。

表格补充说明

以下是关于纺织品含气率的表格补充说明:

| 项目 | 数值 | 单位 | 说明 |

|---|---|---|---|

| 纺织品类型 | 天然纤维 | 如棉、麻等 | 描述纺织品的主要成分 |

| 纤维密度 | 高密度 | g/cm³ | 描述纤维的物理性质 |

| 长度 | 中等长度 | cm | 描述样品尺寸 |

| 测试方法 | 气体吸附法 | 如气体吸附仪等 | 描述用于测量含气率的测试方法 |

| 含气率计算结果 | X% | 无单位 | 根据测试数据计算得出的含气率结果 |

注意事项

在计算纺织品含气率时,需要注意以下几点:

- 选择合适的测试方法,确保测试结果的准确性。

- 在测试过程中,要确保样品在预处理和测试过程中的稳定性。

- 根据测试结果进行分析和判断,确保纺织品的质量和性能符合要求。

纺织品含气率是衡量纺织品质量的重要指标之一,通过选择合适的测试方法,并严格按照操作规程进行操作,可以准确计算出纺织品的含气率,在实际应用中,需要根据具体的产品要求和检测标准进行计算和分析,还需要注意测试过程中的注意事项和误差控制,以确保测试结果的准确性和可靠性。

Articles related to the knowledge points of this article:

The Revolutionary Advancements in the Fabric of Life

The Story of the佛山市禅城区颖兴纺织品批发部

Exploring the World of Textiles:A Journey Through Tide Happy Garment Trading