The Quality Assurance Framework for Pingyang Textiles

The Pingyang Textiles Quality Assurance Framework is a comprehensive set of standards and practices designed to ensure the high-quality and consistency of their products. This framework includes stringent quality control measures, rigorous testing processes, and continuous improvement initiatives aimed at meeting and exceeding customer expectations. The framework is rooted in the belief that only through meticulous attention to detail and constant innovation can a company maintain its position as a leader in the industry. Through this approach, Pingyang Textiles has been able to build strong relationships with its customers, expand its market presence, and become an indispensable partner in the global textile supply chain.

In today's competitive global textile industry, the quality of products is not only a reflection of a company's commitment to excellence but also an essential factor in its survival and success. Pingyang Textiles stands out as a leader in this regard, with a comprehensive quality assurance system that ensures every thread of their fabric meets stringent standards. In this article, we delve into the key pillars of Pingyang’s textile quality management system, including the use of modern technology, stringent quality control measures, regular audits and inspections, and an open communication channel among stakeholders. We will also present a few case studies illustrating how Pingyang has maintained and even exceeded customer expectations through this robust quality assurance framework.

The foundation of any quality assurance program is rigorous adherence to industry standards and regulations. At Pingyang Textiles, these standards are primarily those outlined by the International Organization for Standardization (ISO), which provides guidelines on product design, production process, and testing methods. For instance, the organization recommends the use of advanced digital imaging techniques to enhance product quality during the production stage. By adopting these standards, Pingyang ensures its products meet or exceed internationally recognized quality benchmarks.

Quality control measures are integral to maintaining product quality consistency across all stages of the manufacturing process. These include but are not limited to:

-

Material Source Control: Pingyang ensures that all raw materials used in its textile products are sourced from reputable suppliers who meet strict quality requirements. The company also conducts periodic audits of suppliers to ensure they maintain consistent quality standards.

-

Process Control: The company implements a multi-layered process control system, where each step of the manufacturing process has dedicated quality control personnel responsible for overseeing the accuracy and consistency of the operations. This includes monitoring factors such as yarn strength, fabric thickness, color uniformity, and pattern fidelity.

-

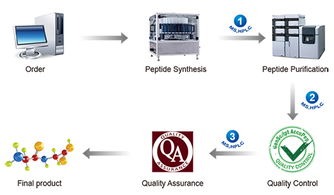

Quality Testing and Verification: After each production run, Pingyang performs thorough quality testing on its products. This includes standardized tests for durability, washability, shrinkage, and resistance to various environmental conditions. The company also uses advanced analytical tools like machine vision and infrared scanners for precision inspection.

-

Feedback Mechanisms: A feedback loop is established within the company wherein customers and partners can report any issues they encounter with Pingyang's products. This data is then analyzed to identify trends, areas for improvement, and potential risks.

An excellent example of how Pingyang Textiles has maintained its high level of quality is through its partnership with luxury fashion house Ralph Lauren. The partnership allowed Pingyang to work closely with renowned designers to ensure that the textiles used in Ralph Lauren's collections met the highest quality standards. This collaboration resulted in a series of successful projects, including exclusive collections designed specifically for Ralph Lauren's flagship stores around the world.

Another noteworthy case study comes from the United States, where Pingyang Textiles was awarded the prestigious "Quality Manufacturer" certification from the National Textile Export Promotion Council. This recognition highlights Pingyang's ability to consistently deliver exceptional quality products to international markets. The certification emphasizes continuous improvements in quality control processes and adherence to international standards, demonstrating Pingyang’s commitment to excellence.

In conclusion, the quality assurance framework employed by Pingyang Textiles stands as a testament to the company's dedication to producing high-quality textiles. By integrating modern technology, strict adherence to quality standards, meticulous process control, rigorous testing, and effective feedback mechanisms, Pingyang has built a reputation for excellence in the textile industry. With its continued focus on innovation and customer satisfaction, it remains a leading player in the global textile market.

平阳纺织品质量概述

平阳作为纺织业的重要基地,其纺织品质量一直备受关注,为了确保纺织品的质量和可靠性,平阳地区采取了一系列措施来保障纺织品的质量保障。

质量保障措施

严格的质量标准体系

平阳地区对纺织品的质量标准有着严格的规定,所有进入市场的纺织品都需要经过严格的质量检测,确保符合相关标准和法规,平阳还建立了完善的追溯体系,以便对纺织品的质量进行全程监控。

质量控制团队

平阳地区拥有一支专业的质量控制团队,他们负责监督和检查纺织品的生产过程和质量,质量控制团队成员具备丰富的专业知识和技能,能够对纺织品进行全面的质量评估和检测。

先进的生产设备和技术

平阳地区注重引进先进的生产设备和技术,以提高纺织品的生产效率和产品质量,平阳还注重技术创新和研发,不断推出新的纺织面料和产品,以满足市场的需求。

质量管理体系的持续改进

为了确保纺织品质量的长期稳定和提高,平阳地区还注重质量管理体系的持续改进,他们定期对质量管理体系进行审查和更新,以确保其适应市场和法规的变化。

案例说明:平阳纺织品质量保障实践

以某知名品牌为例,展示平阳纺织品质量保障的具体实践,该品牌在平阳地区设有生产基地,采用先进的生产设备和技术,严格把控产品质量,该品牌注重质量管理体系的持续改进,不断推出新的产品和服务。

质量检测流程

该品牌在生产过程中,对纺织品进行严格的质量检测,对原材料进行严格把关,确保原材料的质量符合要求,对生产过程进行全面监控,确保生产过程中的各个环节都符合质量标准,对成品进行全面检测和质量评估,确保成品的质量符合要求。

追溯体系的应用

该品牌建立了完善的追溯体系,以便对纺织品的质量进行全程监控,消费者可以通过追溯体系了解产品的生产过程和质量情况,从而更好地选择信任的品牌和产品,该品牌还注重售后服务和质量保证,为消费者提供优质的购物体验。

英文表格补充说明

以下是关于平阳纺织品质量保障的英文表格补充说明:

表格1:平阳纺织品质量保障措施列表

| 措施名称 | 实施效果 | 说明 | |

|---|---|---|---|

| 质量标准体系 | 制定严格的标准和法规 | 确保产品质量符合要求 | 平阳地区对纺织品质量有明确的规定和要求 |

| 质量控制团队 | 专业质量控制团队 | 对纺织品进行全面质量评估和检测 | 平阳地区拥有一支专业的质量控制团队,具备丰富的专业知识和技能 |

| 生产设备和技术 | 引进先进的生产设备和技术 | 提高生产效率和产品质量 | 平阳地区注重引进先进的生产设备和技术,以提高纺织品的生产效率和产品质量 |

| 质量管理体系持续改进 | 定期审查和更新质量管理体系 | 适应市场和法规的变化 | 平阳地区注重质量管理体系的持续改进,确保其适应市场和法规的变化 |

| 品牌实践案例 | 该品牌在平阳地区的生产基地 | 采用先进的生产设备和技术,严格把控产品质量 | 该品牌在平阳地区设有生产基地,采用先进的生产设备和技术,严格把控产品质量,注重质量管理体系的持续改进 |

| 质量检测流程示例 | 对原材料进行严格把关、全面监控、成品检测和质量评估等步骤 | 确保原材料、生产过程、成品的质量符合要求 | 该品牌在生产过程中对纺织品进行严格的质量检测流程示例 |

| 追溯体系应用示例 | 建立完善的追溯体系、消费者了解产品信息等步骤 | 提供优质的购物体验、了解产品的生产过程和质量情况等 | 该品牌建立了完善的追溯体系,消费者可以通过追溯体系了解产品的生产过程和质量情况等 |

平阳地区在纺织品质量保障方面采取了一系列有效的措施和案例实践,通过严格的质量标准体系、专业的质量控制团队、先进的生产设备和技术以及质量管理体系的持续改进等措施,确保了纺织品的质量和可靠性,该地区注重品牌实践和实践案例的应用,为消费者提供优质的购物体验和服务。

Articles related to the knowledge points of this article:

The Role of the National Textile Supervision and Testing Center

Understanding the Super Symbols of Textiles:A Comprehensive Guide

The Unforgettable Experience at Xining Apple Textiles Department Store