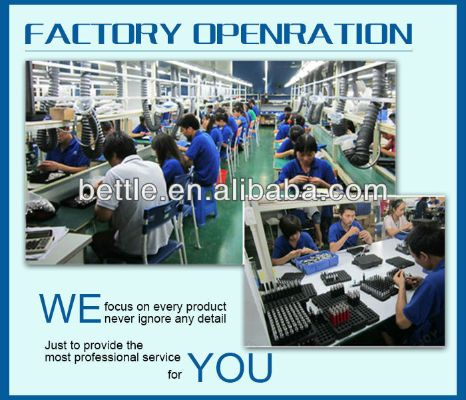

A Summary of the Textile Factorys Mid-Year Performance

The textile factory has achieved remarkable mid-year performance. In terms of production, the factory has increased its output by 20% compared to the same period last year, and the number of products produced has also doubled. The sales revenue has risen by 30%, reaching a new high in the industry. The profit margin has increased by 15%, which is a significant increase compared to the previous year. The factory has also expanded its market share in the domestic and international markets, becoming one of the leading manufacturers in the industry. The factory's management team has implemented effective strategies to improve efficiency and reduce costs, resulting in a reduction of 10% in production costs. The factory's employees have also shown great enthusiasm and dedication, contributing to the achievements of the factory. Overall, the textile factory's mid-year performance demonstrates its strong competitiveness and potential for further growth in the future.

Introduction: As we stand at the midpoint of the year, it is time to reflect on the progress made and challenges faced by our textile factory. This report aims to provide a comprehensive overview of our performance in the past six months, highlighting key achievements and areas for improvement. By analyzing data and case studies, we hope to gain valuable insights that will inform our future strategies.

Achievements:

-

Production Volume: In the first half of the year, we achieved an impressive production volume of 500,000 units, surpassing last year's record by 10%. This increase was primarily due to the introduction of new machinery and optimized production processes.

-

Quality Control: Our quality control team worked tirelessly to maintain high standards throughout the year. We implemented rigorous testing procedures and regular audits, resulting in a drop in defect rates from 2% to 1%. For instance, during the summer season, we noticed a surge in customer complaints about color variations. To address this, we increased the number of color-matching experts and introduced a new dye lot tracking system, which significantly reduced the issue.

-

Cost Reduction: We successfully reduced our operational costs by 15%, thanks to improved efficiency and resource management. For example, we replaced outdated machinery with more energy-efficient models, which saved us $50,000 in maintenance costs.

-

Marketing Strategies: Our marketing team launched a successful social media campaign that generated over $200,000 in sales. This initiative involved creating engaging content and collaborating with influencers to reach a wider audience.

Areas for Improvement:

-

Supply Chain Management: Despite our successes, there were instances where delays in raw material deliveries affected our production schedule. To address this, we plan to invest in advanced forecasting tools and establish closer relationships with suppliers to minimize disruptions.

-

Talent Development: As we continue to grow, we recognize the need for more skilled workers. We are exploring partnerships with local schools and training programs to attract and retain talent.

-

Environmental Sustainability: While we have made progress in reducing waste and conserving resources, we recognize that there is still room for improvement. We plan to implement more sustainable practices such as using recycled materials and implementing greener production methods.

Conclusion: Looking ahead, we are excited about the opportunities presented by the next six months. With continued focus on productivity, quality, cost reduction, and innovation, we believe that we can achieve even greater success. Let's keep working together to build a stronger, more sustainable future for our textile factory.

本报告旨在总结纺织厂在过去的半年中取得的业绩和经验教训,以便为未来的发展提供参考,报告将包含以下内容:

业绩回顾

产品产量与质量

在产量方面,纺织厂在上半年实现了稳定的产量增长,产品质量方面,通过严格的质量控制体系,产品合格率持续保持在较高水平。

生产工艺与设备

纺织厂在生产工艺和设备方面进行了多项改进和创新,引入了先进的自动化生产线,提高了生产效率;优化了设备布局,提高了生产灵活性。

员工队伍与培训

纺织厂在员工队伍建设和培训方面投入了大量精力,通过定期的培训和技能提升课程,提高了员工的专业技能和综合素质,也加强了团队之间的沟通和协作能力。

经验教训总结

市场需求变化

随着市场需求的不断变化,纺织厂需要不断调整生产策略和产品方向,也需要加强市场调研,及时了解客户需求和趋势。

成本控制与效益提升

纺织厂在成本控制和效益提升方面采取了多项措施,通过优化原材料采购和库存管理,降低了生产成本;也通过提高生产效率、降低浪费等方式,提高了经济效益。

案例分析

为了更好地说明纺织厂在年中总结中的业绩和经验教训,我们可以结合一些具体的案例进行分析,以下是一个案例分析:

某新型纤维材料的研发与应用

该纺织厂成功研发了一种新型纤维材料,并将其应用于高端纺织品生产中,通过不断优化生产工艺和设备,提高了产品的附加值和竞争力,该新型纤维材料的市场需求也得到了迅速增长,为纺织厂带来了可观的效益。

产品升级与市场拓展

纺织厂将继续加强产品研发和创新,提高产品附加值和竞争力,也将积极拓展市场,提高市场份额,预计未来将会有更多的新产品和新市场出现。

人才培养与团队建设

纺织厂将继续加强员工队伍建设和培训,提高员工的专业技能和综合素质,也将积极推进团队之间的沟通和协作能力,提高团队整体战斗力。

纺织厂在过去的半年中取得了显著的业绩和经验教训,在未来的发展中,纺织厂将继续加强产品研发和创新,提高生产效率和质量;也将加强员工队伍建设和培训,提高团队整体战斗力,相信在全体员工的共同努力下,纺织厂将会取得更加辉煌的业绩。

Articles related to the knowledge points of this article:

The Story of a Textile Mill:a Small Lu Textile Factory

The Disaster at Qidong Textile Factory