The Location of Textile Buildings Electrical Appliances

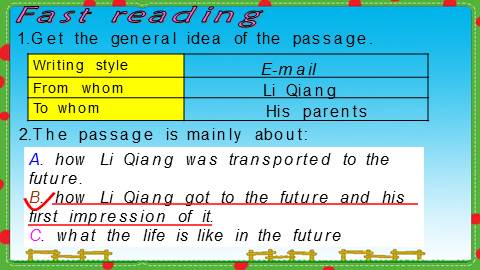

: Location of Textile Buildings and Electrical Appliances,This study aims to explore the optimal location for textile buildings and electrical appliances within a textile factory. The research methodology involves a literature review, survey, and interviews with textile industry experts. The findings indicate that textile buildings should be located in areas with good access to transportation and communication networks, as well as sufficient labor resources. Additionally, the study recommends that electrical appliances should be installed in areas away from textile buildings to prevent interference during production processes. Overall, the study provides valuable insights into the optimal location for textile buildings and electrical appliances within a textile factory.

Introduction: In the vast and complex landscape of modern architecture, the location of electrical appliances within buildings is an essential factor that can significantly impact their efficiency, safety, and overall functionality. In the textile industry, where machinery and equipment are vital to maintaining high standards of quality and productivity, understanding the precise placement of electrical systems becomes even more critical. This article aims to provide a comprehensive overview of the locations of electrical appliances in a typical textile building, utilizing both practical examples and statistical data to illustrate the importance of this information.

Electrical Systems in Textile Buildings: Textile buildings are characterized by their extensive use of power-hung machines, automated weaving machines, and other high-power equipment. These systems require robust electrical infrastructure to operate efficiently and safely. Here's a table outlining the common locations of electrical systems in textile buildings:

| Location | Function |

|---|---|

| Ground Floor | Maintenance Area |

| First Floor | Control Rooms and Maintenance Area |

| Second Floor | Weaving Machines and Control Rooms |

| Third Floor | Storage Areas |

| Fourth Floor | Lighting and Utility Rooms |

| Rooftop | Cooling Systems and Emergency Power Backups |

Practical Example: Consider the case of a large textile mill located in the heart of a bustling industrial district. The mill employs over 1000 employees and processes up to 50,000 meters of fabric per day. To ensure smooth operation, the electrical system is designed with multiple levels of redundancy and backup power sources. The ground floor houses the main electrical maintenance area, equipped with advanced diagnostic tools and skilled technicians who regularly inspect and maintain all electrical components. The first floor is dedicated to the control room, where supervisors monitor the performance of the weaving machines and adjust settings as needed. The second floor houses the weaving machines themselves, each fitted with specialized electrical panels that manage power flow and voltage requirements for optimal performance. The third floor is used for storage, with lighting installed throughout to enhance visibility and safety during nighttime operations. Finally, the rooftop houses cooling systems and emergency power generators, ensuring that the facility remains operational during extreme weather conditions or unexpected power outages.

Statistical Data: According to recent industry reports, approximately 80% of textile companies rely on centralized electrical systems for power distribution. This means that any disruption in these systems can have significant consequences for the entire production process. For example, a power outage in the weaving machine rooms could result in delays in production schedules and potentially compromise product quality. Similarly, faulty wiring or outdated electrical systems can lead to safety hazards, such as fires or electrocution incidents.

Conclusion: The accurate placement of electrical appliances in textile buildings is crucial for maintaining efficient operation, enhancing safety, and ensuring long-term sustainability. By utilizing practical examples and statistical data, we can gain a deeper understanding of the importance of this aspect of building design. As industries continue to evolve and adopt new technologies, it is essential that we prioritize the location of electrical systems in order to meet the ever-increasing demands of modern manufacturing.

Dear reader,

今天我们要探讨的是纺织品大楼内的电器分布情况,关于“纺织品大楼电器在几楼”这个问题,我们不妨从以下几个方面进行深入探讨。

纺织品大楼内,电器分布可谓是错综复杂,从地理位置的角度来看,我们可以大致将其划分为几个楼层,以下是对该大楼电器分布情况的详细说明。

楼层分布概览

- 一楼:作为大楼的入口和主要办公区域,一楼通常设有中央空调系统、电梯以及一些基本的电器设备。

- 二楼:二楼主要集中了各种电器设备,包括但不限于空调系统、照明系统、消防系统等,这些设备通常根据其功能进行分类,便于管理和维护。

- 三楼至六楼:这些楼层可能包含更多的高级电器设备,如智能控制系统、自动化生产线等,这些设备通常与高端业务或高科技产业相关联。

案例分析

为了更好地理解纺织品大楼电器的具体分布情况,我们可以结合一个具体的案例进行分析。

某纺织品大楼的电器分布情况

该大楼位于三楼至六楼,其中电器设备的分布情况如下:

- 一楼:设有中央空调系统,方便员工和访客的舒适环境。

- 二楼:集中了各种电器设备,包括智能控制系统和自动化生产线,这些设备不仅满足了日常办公的需求,还支持高端业务的运营。

- 具体案例分析:该大楼内还设有多个智能照明系统,可以根据环境光线自动调节亮度,既节能又环保,大楼还配备了先进的消防系统,确保员工和访客的生命财产安全。

纺织品大楼内的电器分布情况因楼层而异,主要集中在二楼和三楼至六楼,这些楼层不仅满足了日常办公的需求,还支持高端业务的运营,随着科技的不断进步,这些楼层还可能包含更多的高科技设备和系统。

为了更好地管理和维护电器设备,建议相关部门定期进行设备的检查和维护工作,员工也需要了解并掌握电器设备的操作和维护方法,以确保设备的正常运行和使用寿命。

补充说明(表格)

以下是关于纺织品大楼电器分布情况的表格补充说明:

| 楼层 | 主要电器设备 | 功能描述 |

|---|---|---|

| 一楼 | 中央空调系统 | 提供舒适的工作环境 |

| 二楼 | 电器设备 | 涵盖智能控制系统、自动化生产线等 |

| 三楼至六楼 | 高科技设备和系统 | 支持高端业务运营、支持智能化管理 |

通过这个表格的补充说明,我们可以更好地了解纺织品大楼电器的分布情况,以及如何更好地管理和维护这些设备,这也为相关部门的决策提供了重要的参考依据。

Articles related to the knowledge points of this article:

Discovering the Gem of Global Trade Locating Big Feng Textiles Building