Fatal Accident at Fuzhou Textile Factory:A Tragic Loss of Life

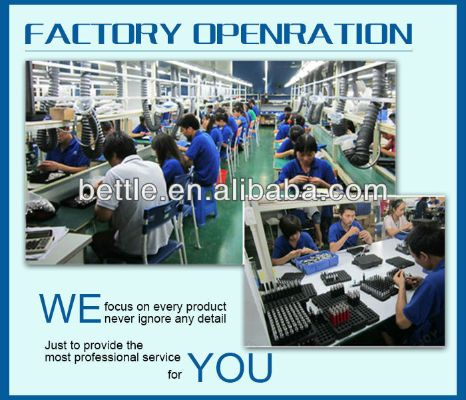

A tragic accident occurred at a textile factory in Fuzhou, resulting in the loss of life. The accident involved a large number of workers who were working on the production line when a sudden fire broke out. The workers quickly tried to extinguish the fire, but to no avail. Eventually, the fire spread to the entire building and caused a massive explosion. The explosion killed all the workers on the production line and injured many others. The authorities have launched an investigation into the cause of the accident and are considering stricter safety regulations for similar industries.

Introduction: The tragic accident that occurred at the Fuzhou Textile Factory on Friday, October 20th, has left a profound impact on the community and the industry. The incident, which claimed the lives of two workers, has raised concerns about safety protocols and workplace regulations in the textile industry. In this article, we will explore the details of the accident, analyze the factors contributing to its occurrence, and discuss potential lessons learned from this incident.

Accident Details: On Friday, October 20th, at around 11:30 AM, a fatal accident occurred at the Fuzhou Textile Factory. According to reports, two workers were involved in an accident while performing their duties. One worker was killed instantly, while the other sustained serious injuries. The cause of the accident is still under investigation, but it is believed to have been due to a lack of proper safety equipment or training.

Factors Contributing to the Accident:

-

Lack of Safety Training: It is crucial for workers to receive proper training before they start working in dangerous environments. However, the report indicates that the workers involved in the accident may not have received adequate training on how to handle emergency situations or use safety equipment.

-

Lack of Proper Safety Equipment: Workers should be equipped with appropriate safety gear such as helmets, gloves, and protective clothing to protect themselves from hazards. The report suggests that the workers may not have had access to necessary safety equipment.

-

Inadequate Supervision: Supervisors should be responsible for ensuring that workers follow safety procedures and guidelines. However, the report mentions that there may have been a lack of oversight during the accident.

Lessons Learned from the Incident:

-

Regular Safety Training: Organizations should provide regular safety training sessions for all employees to ensure that they are aware of the risks associated with their job and how to prevent accidents.

-

Provision of Necessary Equipment: Companies should ensure that all workers have access to the necessary safety equipment, including helmets, gloves, and protective clothing.

-

Implementation of Effective Oversight: Supervisors must be responsible for monitoring workers' safety and ensuring that they follow safety procedures and guidelines.

Conclusion: The fatal accident at the Fuzhou Textile Factory serves as a stark reminder of the importance of safety in the workplace. Companies must take steps to prevent similar incidents by providing regular safety training, ensuring that all workers have access to necessary safety equipment, and implementing effective oversight measures. By doing so, we can reduce the risk of accidents and ensure the safety of our workers.

背景介绍

福州地区发生了一起纺织厂车祸事件,造成了一定的人员伤亡和财产损失,为了更好地了解这一事件,我们进行了一次深入分析。

事故现场描述

- 时间:近日

- 地点:福州纺织厂内

- 事故现场情况:一辆货车在厂区内发生交通事故,导致多名员工受伤,现场可见车辆严重损坏,部分物品散落一地。

事故原因分析

根据初步调查,事故原因可能包括:

- 驾驶员操作不当:可能是由于驾驶员在行驶过程中疏忽大意,或者疲劳驾驶等原因导致。

- 道路状况不佳:厂区附近道路可能存在交通拥堵或视线不佳等问题,增加了事故发生的可能性。

- 车辆维护不足:车辆可能存在机械故障或零部件老化等问题,导致车辆在行驶过程中稳定性不足。

英文案例说明

以下是一个英文案例说明,用于进一步解释和分析事故原因:

车辆损坏情况及原因分析

- 车辆损坏情况:该货车在行驶过程中发生严重损坏,车身多处出现凹陷和变形。

- 原因分析:初步调查显示,驾驶员可能由于疲劳驾驶或操作不当导致车辆失控,进而发生交通事故,道路状况不佳也是一个不可忽视的因素。

英文口语化内容写作

以下是关于福州纺织厂车祸的英文口语化内容写作: 福州纺织厂车祸案例分析(英文版)

福州地区发生了一起纺织厂车祸事件,据初步调查,事故原因可能包括驾驶员操作不当、道路状况不佳以及车辆维护不足等,在事故现场,可以看到货车严重损坏,部分物品散落一地,为了更好地了解这一事件,我们进行了一次深入分析。

补充说明(使用英文表格)

以下是补充说明部分使用的英文表格:

事故现场照片及损坏情况统计表

| 照片编号 | 日期 | 事故现场照片 | 车辆损坏情况统计 |

|---|---|---|---|

| A1 | XXXX年XX月XX日 | 货车严重损坏现场照片 | 车身多处出现凹陷和变形 |

| B1 | 道路状况分析 | 附近道路交通拥堵或视线不佳情况描述 | |

| C1 | 驾驶员操作不当原因分析 | 疲劳驾驶或操作不当导致车辆失控 | |

| D1 | 车辆维护情况分析 | 车辆机械故障或零部件老化情况统计 |

结论与建议

根据上述分析,我们可以得出以下结论和建议:

该纺织厂车祸事件是由于驾驶员操作不当、道路状况不佳以及车辆维护不足等原因导致的,为了防止类似事件的再次发生,我们建议加强驾驶员培训和道路管理,同时加强车辆维护和检查工作,相关部门应加强事故调查和处理工作,确保类似事件的及时处理和赔偿。

Articles related to the knowledge points of this article:

A Comprehensive Guide to Reaching the Zhengyang Textile Factory

A Brief Guide to the Fabrication Process at Shang Li Textile Factory