Navigating the Nuances of Textile Physical Metrics for Quality Assurance

: Navigating the Nuances of Textile Physical Metrics for Quality Assurance,Abstract:,This paper discusses the complexities involved in ensuring textile quality through the application of physical metrics. The focus is on understanding and interpreting these metrics to accurately assess the performance of textile products. The study highlights the importance of standardized testing procedures, as well as the need for continuous monitoring and evaluation to maintain product quality. The paper also emphasizes the role of advanced technologies in enhancing the accuracy and efficiency of physical metric measurements. Overall, the discussion underscores the significance of integrating physical metrics into a comprehensive quality assurance framework for textile products.

Introduction: In the realm of textile manufacturing, achieving "textile physical metrics detection and acceptance" is a cornerstone of product quality assurance. This process involves rigorous testing to ensure that textile products meet certain physical standards, including but not limited to strength, durability, colorfastness, and conformity with specific dimensions. By understanding these parameters and their implications, manufacturers can optimize production processes, reduce waste, and enhance customer satisfaction.

Textile Physical Metrics: The term "textile physical metrics" encompasses a wide range of properties that define the performance and end-use characteristics of textile materials. Some common metrics include:

- Tensile Strength: The maximum force required to tear apart a textile sample under controlled conditions.

- Tear Resistance: The ability of a textile material to resist tearing when subjected to a pulling force.

- Elongation: The percentage increase in length of a textile sample after being stretched.

- Dyestuff Resistance: The resistance of a textile material to the penetration of dyestuffs during dyeing or printing processes.

- Dimensional Stability: The ability of a textile material to maintain its shape and size over time.

- Colorfastness: The resistance of a textile material to color fading or loss when exposed to light, heat, or chemicals.

- Shrinkage: The change in size of a textile sample after exposure to heat or other environmental factors.

- Crease Recovery: The ability of a textile material to regain its original shape after being creased.

- Weave Density: The number of warp and weft threads per square inch in a given area of fabric.

Case Study: Consider a manufacturer who produces high-quality sportswear using polyester fabrics. To ensure that their products are up to standard, they conduct regular tests on their fabrics for various physical metrics. For example, they might test the tensile strength of the fabrics to ensure they can withstand the strain required for athletic activities. They also evaluate the colorfastness of the fabrics during washing and wear to prevent fading and loss of color.

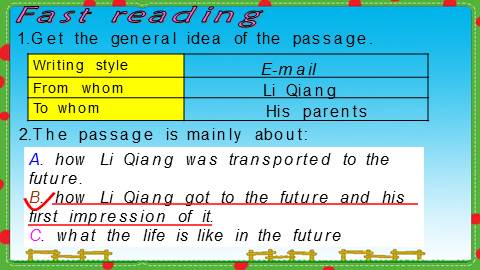

Testing Procedures: To achieve "textile physical metrics detection and acceptance," manufacturers typically follow a systematic approach involving several stages:

-

Pre-production Testing: This stage involves conducting preliminary tests on raw materials to identify any potential issues before full-scale production begins. This could include measuring the density of the fibers, assessing the strength of the yarns, or determining the colorfastness of the dyestuffs.

-

In-process Monitoring: During the manufacturing process, continuous monitoring is essential to ensure that the physical properties of the fabrics remain within acceptable limits. This may involve using automated testing equipment or manual inspection by trained personnel.

-

Post-Production Verification: After the final product has been produced, it undergoes thorough testing to confirm that it meets all specified physical metrics. This may include further testing on the fabrics to measure dimensional stability, colorfastness, and any other relevant properties.

-

Documentation and Recordkeeping: All testing results and data should be accurately documented and maintained in a database for future reference. This ensures that any discrepancies can be quickly identified and addressed.

Benefits of Physical Metrics Testing: By implementing a comprehensive physical metrics testing program, manufacturers can gain several benefits:

- Enhanced Product Quality: Accurate testing ensures that every piece of fabric produced meets industry standards, leading to higher quality products that meet consumer expectations.

- Cost Savings: Early detection of defects can lead to significant cost savings by avoiding costly rework or scrapping operations.

- Compliance with Regulations: Many industries have regulations that require textile products to meet specific physical metrics. Regular testing can help manufacturers stay compliant with these regulations without incurring penalties.

- Customer Trust: A commitment to quality through consistent testing can build trust with customers, as they know that their products will perform as intended.

Conclusion: In conclusion, achieving "textile physical metrics detection and acceptance" is crucial for ensuring the quality and reliability of textile products. By following a structured testing protocol that includes pre-production testing, in-process monitoring, post-production verification, and documentation, manufacturers can optimize their production processes, minimize waste, and deliver products that exceed customer expectations. As the case study illustrates, regular testing not only enhances product quality but also contributes to cost savings, regulatory compliance, and customer trust.

大家好,今天我们来聊聊纺织品物理指标检测合格的话题,在纺织品生产和销售过程中,物理指标检测是非常重要的一环,它直接关系到产品的质量和消费者的使用体验,下面我们将通过英文案例和表格来详细说明。

纺织品物理指标概述

纺织品物理指标主要包括密度、强度、光泽度、吸水性、透气性等,这些指标反映了纺织材料的物理特性,是衡量纺织品质量的重要依据,在检测过程中,合格的纺织品必须符合相关标准,以确保产品的安全性和可靠性。

检测流程与标准

检测流程:

a. 样品准备:根据检测需求,准备符合标准的纺织品样品。 b. 仪器使用:使用专业的物理检测仪器进行样品检测。 c. 数据采集:记录并分析检测数据,确保数据的准确性和可靠性。 d. 结果报告:根据检测结果出具合格证书或报告。

相关标准:

a. 密度标准:根据不同纺织材料的种类和用途,制定相应的密度标准。 b. 强度测试:评估纺织材料的抗拉强度、撕裂强度等指标。 c. 其他指标标准:根据实际需求,可能还需检测光泽度、吸水性、透气性等其他指标。

案例说明

以某品牌纺织品为例,其物理指标检测合格的具体情况如下:

- 样品准备:该品牌提供多种材质的纺织品样品,包括纯棉、涤纶等。

- 仪器使用:使用专业的纺织品物理检测仪器进行样品检测,包括密度测试仪、强度测试仪等。

- 数据采集:经过检测,该品牌纺织品的各项物理指标均符合相关标准,密度适中,强度较高,光泽度良好,吸水性适中,透气性好等。

- 结果报告:根据检测结果出具纺织品物理指标合格证书或报告,明确指出该品牌纺织品的各项指标均符合国家标准,质量可靠。

表格补充说明

以下是关于纺织品物理指标检测的表格补充说明:

| 项目 | 数值 | 单位 | 合格标准 |

|---|---|---|---|

| 密度 | 根据不同纺织材料种类和用途制定 | g/cm³ | 根据国家标准执行 |

| 强度 | 根据不同测试方法评估 | N/cm² | 根据行业标准执行 |

| 光泽度 | 通过光泽度计测量 | 在规定范围内 | |

| 吸水性 | 通过吸水性测试仪测量 | 在规定范围内 | |

| 透气性 | 通过透气性测试仪测量 | mm³/s | 根据不同产品类型和用途制定 |

总结与展望 我们可以了解到纺织品物理指标检测合格的重要性以及具体流程和标准,在纺织品生产和销售过程中,必须严格遵守相关标准和要求,以确保产品的质量和消费者的使用体验,随着科技的不断进步和人们对纺织品质量要求的不断提高,纺织品物理指标检测将更加严格和规范,我们期待看到更多的纺织品生产企业能够严格按照相关标准和要求进行生产和销售,为消费者提供更加安全、可靠的产品。

Articles related to the knowledge points of this article:

Understanding and Applying Textile Stretch Testing Devices

Trends and Prices in Laiyuan Textile Markets Socks

The Density of Textiles:A Technical Exploration