The Art of Nantong Mi-dyed Textiles:Crafting Timeless Styles

: The Art of Nantong Mi-dyed Textiles: Crafting Timeless Styles,Nantong, a city in Jiangsu Province, China, is renowned for its exquisite mi-dyed textiles that embody the essence of traditional Chinese culture. Mi-dyed textiles are characterized by their vibrant colors, intricate patterns, and timeless styles that have been passed down through generations. In this article, we will explore the art of Nantong mi-dyed textiles and how they have become an integral part of Chinese culture.,The art of mi-dying involves using natural dyes derived from plants or minerals to create unique shades and patterns on textiles. In Nantong, artisans use a variety of natural ingredients such as indigo, turmeric, and madder to produce vibrant hues that range from deep blues to bright yellows. These dyes are carefully extracted from plants and minerals before being applied to the fabric, which takes several weeks to dry completely.,Once the dye has dried, the textile is then washed and rinsed with water to remove any excess dye or impurities. This process is known as "washing" and is crucial in ensuring that the colors remain consistent throughout the textile. After washing, the textile is ready for further processing, such as blocking (to prevent bleeding) or finishing (to enhance texture).,In addition to the dyeing process, Nantong mi-dyed textiles also incorporate various techniques to create intricate patterns and designs. For example, some artisans use wax resisting methods to create raised patterns on the fabric, while others use silk screening techniques to create delicate floral designs. These techniques not only add visual interest to the textile but also provide a tactile experience for the wearer.,Overall, Nantong mi-dyed textiles represent a beautiful blend of tradition and innovation. They showcase the skill and expertise of local artisans who have been producing these textiles for centuries. Today, these textiles continue to be cherished by people around the world for their unique beauty and cultural significance.

In the tapestry of Chinese textile history, Nantong, a city renowned for its exquisite handicrafts, stands as a testament to traditional craftsmanship and innovation. One such craft that has captivated the hearts and minds of global textile enthusiasts is the art of Nantong mi-dyeing. This method of dyeing involves using natural materials like rice or soybeans to create vibrant colors on fabrics, imparting a timeless charm that transcends generations.

At Nantong Mi-Dyeing Textile Factory, artisans employ a meticulous process that combines traditional techniques with modern innovations to produce high-quality textiles that are not only aesthetically pleasing but also sustainable. The factory's dedication to sustainability extends beyond just the use of eco-friendly materials; it encompasses every aspect of its operations, from sourcing raw materials to designing and producing the finished products.

To understand the depth of this craft, let us delve into the various steps involved in Nantong mi-dyeing, as well as some case studies that illustrate how these techniques have been applied to create timeless textiles.

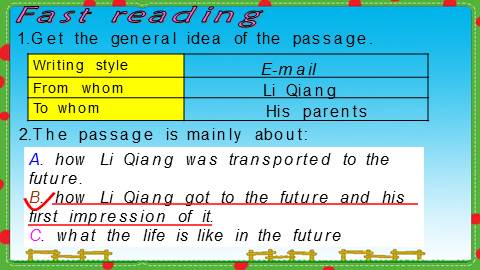

Step-by-Step Process of Nantong Mi-Dyeing

-

Preparation: The first step in the dyeing process is preparation. This includes selecting the appropriate fabric, determining the type of dye to be used, and preparing the dye solution. In the case of Nantong mi-dyeing, natural materials like rice or soybeans are often used as the dye source. These materials are ground into a fine powder and mixed with water to create a dye bath.

-

Dyeing: Once the fabric is ready, it is immersed in the dye bath. The duration of the dyeing process varies depending on the desired color intensity and texture. Some artisans prefer to use a longer soaking time to achieve a deeper, more vibrant color, while others opt for a shorter exposure to achieve a lighter shade.

-

Rinsing: After the dyeing process, the fabric is rinsed thoroughly to remove any excess dye and prevent fading. This step is critical in maintaining the vibrancy and longevity of the dyed textiles.

-

Drying: The fabric is then dried either by air or by using a special drying technique known as "baking." Baking involves placing the fabric in a heated oven or on a hot stone to dry it quickly and evenly. This ensures that the dye remains firmly attached to the fabric fibers, preventing fading over time.

-

Quality Control: Finally, the finished product undergoes rigorous quality control checks to ensure that each piece meets the standards set by the factory. This includes measuring the color consistency, checking for any defects, and ensuring that the fabric is of high quality.

Case Studies

One notable example of Nantong mi-dyeing is the creation of a linen shirt by the factory. The shirt was designed to showcase the rich, earthy tones of the dyed fabric. Using a combination of rice and soybean dyes, the artisans achieved a deep blue hue that complemented the natural fibers of the linen. The result was a shirt that not only looked stunning but also felt luxurious against the skin.

Another highlight is the factory's collaboration with a local artist who used Nantong mi-dyed fabrics to create a collection of handbags. The bags were designed to reflect the beauty of the natural dyes and were made using locally sourced materials. The resulting products were not only visually stunning but also environmentally conscious, showcasing the factory's commitment to sustainability.

Sustainability at Nantong Mi-Dyeing Factory

At Nantong Mi-Dyeing Textile Factory, sustainability is not just an optional feature; it is a core value that guides every aspect of the production process. From sourcing eco-friendly raw materials to designing and producing eco-conscious products, the factory prioritizes reducing waste, conserving resources, and minimizing environmental impact.

The factory's commitment to sustainability extends beyond just the use of eco-friendly materials; it encompasses every aspect of its operations, from sourcing raw materials to designing and producing the finished products. By adopting sustainable practices, the factory is not only protecting the environment but also creating long-lasting, high-quality textiles that will continue to inspire and delight customers for generations to come.

In conclusion, Nantong mi-dyeing is not just a craft; it is a way of life. At the Nantong Mi-Dyeing Textile Factory, artisans use their skills and passion to create timeless textiles that are not only beautiful but also sustainable. With a commitment to innovation, sustainability, and tradition, this factory continues to be a beacon of excellence in the world of textiles.

南通米染纺织品厂概述

南通米染纺织品厂位于江苏省南通市,是一家专注于米染纺织品研发、生产和销售的企业,该厂秉承传统工艺,结合现代技术,致力于打造高品质、环保、时尚的纺织品。

南通米染纺织品厂的产品特点

- 原料选取:采用优质稻米为主要原料,经过精心挑选和加工,确保产品质量。

- 米染工艺:采用传统工艺,结合现代科技,使纺织品具有独特的米色和纹理。

- 环保理念:注重环保,采用环保染料和环保生产方式,确保纺织品符合国家环保标准。

- 时尚元素:结合现代审美观念,融入时尚元素,打造符合市场需求的产品。

南通米染纺织品厂的案例分析

成功案例 近年来,南通米染纺织品厂在纺织行业取得了显著成就,该厂的产品深受消费者喜爱,市场份额逐年上升,其成功的原因在于始终坚持传统工艺,注重产品质量和环保,同时不断引进先进技术,提高生产效率,该厂还注重品牌建设,不断提升自身竞争力。

南通米染纺织品厂的发展策略

- 传统工艺传承:继续传承和发扬传统工艺,注重产品质量和环保,打造高品质、环保、时尚的纺织品。

- 技术创新:不断引进先进技术,提高生产效率,降低成本,提高市场竞争力。

- 品牌建设:注重品牌建设,提升品牌知名度和美誉度,打造自己的品牌特色。

- 市场营销:加强市场营销策略,提高产品知名度和市场份额。

南通米染纺织品厂的未来展望

展望未来,南通米染纺织品厂将继续秉承传统工艺,注重产品质量和环保,同时不断引进先进技术,提高生产效率,该厂还将注重品牌建设,提升品牌知名度和美誉度,该厂还将加强与国际市场的合作,拓展国际市场,打造国际品牌。

英文表格补充说明

南通米染纺织品厂产品信息表

| 产品名称 | 主要原料 | 米染工艺 | 环保理念 | 时尚元素 | 生产方式 | 价格范围 |

|---|---|---|---|---|---|---|

| 米色纺织品 | 优质稻米 | 传统工艺 + 现代科技 | 环保 | 结合现代审美观念融入时尚元素 | 生产、销售 | 根据品质和市场需求而定 |

| 其他产品描述 |

英文案例说明

以南通米染纺织品厂为例,其成功案例可以参考以下英文案例:某纺织公司在南通米染纺织品厂的帮助下成功研发出具有独特米色和纹理的高品质纺织品,该公司在传统工艺的基础上结合现代科技,采用环保染料和环保生产方式,注重产品质量和环保,该公司还注重品牌建设,不断提升自身竞争力,通过不断的市场营销策略,该公司的产品深受消费者喜爱,市场份额逐年上升。

Articles related to the knowledge points of this article:

The Artful Symmetry in Designing Fashion Textiles

The Art of Textile Labels and Their Incredible Benefits for Customers

The Characteristics of the纺织服装行业

Unlocking the Benefits of EPR Compliance for French Textile Exporters