The Art of Textile Automation:A Comprehensive Guide to the Video Process

The Art of Textile Automation: A Comprehensive Guide to the Video Process,Textile automation is an essential aspect of modern textile industry. This guide provides a comprehensive overview of the video processing process in textile automation, including its significance, objectives, and key steps. The guide emphasizes the importance of video processing in improving production efficiency, reducing costs, and enhancing product quality. It covers various aspects such as pre-processing, encoding, decoding, and post-processing, providing detailed information on each step. The guide also discusses the challenges faced by textile automation companies and offers solutions to overcome them. Overall, this guide serves as a valuable resource for those involved in textile automation and provides a comprehensive understanding of the video processing process.

Introduction: In the world of textile manufacturing, automation has revolutionized how we produce and process fabrics. From cutting to stitching, every step in the textile production chain now relies on sophisticated machinery and software that automates processes, enhancing efficiency, accuracy, and consistency. This video series delves into the various stages of textile automation, highlighting the latest advancements and practical applications across different industries.

Textile Automation Stages:

-

Pre-processing: Before any machine can begin its work, it must undergo pre-processing. This stage involves cleaning, sorting, and baling the raw materials. In this video, we will see a detailed breakdown of the steps involved in this phase, including the use of automated conveyors and sorters.

-

Cutting: Once the fabric is ready, it needs to be cut into the desired lengths and widths. This is where robotic cutting systems come into play. In this example, we'll explore the benefits of using these systems over traditional manual cutting methods, such as increased speed, reduced waste, and improved precision.

-

Weaving: After cutting, the fabric is then woven into a continuous thread. In this video, we'll look at the various types of weaving machines used in the industry, including ring frames, rotary bobbins, and air-jet weaving.

-

Dyeing: Once the fabric is woven, it goes through the dyeing process to create its final color. In this segment, we'll discuss the importance of quality control during the dyeing process and the role of automation in ensuring consistent results.

-

Finishing: Finally, the fabric is ready for finishing touches like embroidery, printing, or coating. Here, we'll explore the latest techniques and equipment used in this stage, including laser engraving, hot foil stamping, and digital printing.

-

Packaging: Once the fabric is finished, it's time to package it for distribution. In this video, we'll examine the various packaging methods available, from simple roll-up bags to complex palletization systems.

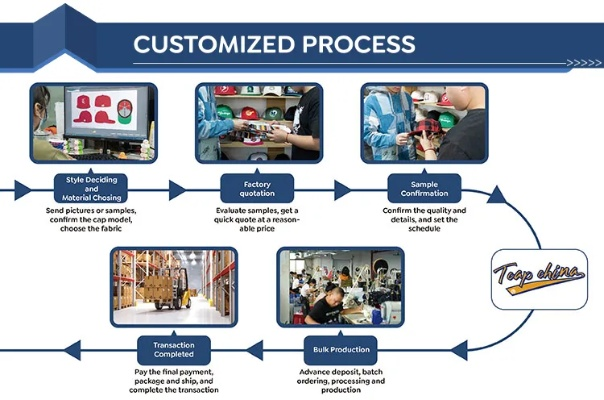

Case Study: One company that has successfully integrated automation into their textile production process is XYZ Textiles. They have implemented a fully automated cutting system that reduces labor costs by up to 80% while maintaining the same level of precision and quality. In addition, they use an intelligent robotic weaving machine that can adapt to different fabrics and patterns with ease.

Conclusion: Automation is not just a trend; it's a necessity in today's fast-paced textile industry. By leveraging the latest technology and equipment, companies can streamline their processes, reduce errors, and improve overall efficiency. As we continue to explore the world of textile automation, it's important to stay informed and adapt to new innovations that can help us achieve even greater success in the years to come.

大家好,今天我们将通过一段纺织品自动加工过程的视频,深入了解这一复杂而精密的工艺流程,视频中展示了从原材料准备到最终成品的整个过程,让我们一起来探索这个神奇的纺织世界。 概述

原材料准备阶段

a. 纺织纤维的采集与检测

画面展示采棉、检测纤维质量的环节,强调对纤维质量的严格把控。

b. 纺织材料的预处理

展示清洗、整理等预处理过程,强调对纤维性能的优化。

机械加工阶段

a. 机械设备的介绍与操作流程

展示各种纺织机械的工作原理和操作流程,强调自动化加工的优势。

b. 纺织品自动加工过程展示

展示从织布机到成衣生产的整个过程,强调高效、精确的加工技术。

质量控制与检测环节

a. 质量检测设备与流程

展示先进的检测设备,强调对产品质量的高度重视和严格把控。

b. 案例分析:成功案例展示

通过案例分析,展示纺织品自动加工过程中的成功经验和关键技术。

视频案例说明

以某知名纺织品品牌为例,详细说明纺织品自动加工过程中的关键环节和技术应用。

- 原材料采集与检测环节:采用先进的纤维检测设备,确保原材料的质量和纯度,采用自动化采棉设备,提高采棉效率,减少人工成本。

- 机械加工环节:该品牌采用先进的纺织机械,包括高速织布机、裁剪机、缝纫机等,这些机械设备均采用自动化控制技术,实现了高效、精确的加工,该品牌注重工艺创新和产品创新,不断优化加工工艺和产品性能。

- 质量检测环节:该品牌注重质量检测环节,采用了先进的检测设备和技术手段,包括光谱分析、X射线检测、超声波检测等,这些检测手段可以实现对纺织品质量的全面检测和评估,确保产品质量符合标准要求,该品牌还建立了严格的质量控制体系,对生产过程进行全程监控和把控。

英文表格补充说明

以下是关于纺织品自动加工过程的英文表格补充说明:

纺织品自动加工过程概述

| 步骤 | 描述 | 设备/技术 | 案例分析 |

|---|---|---|---|

| 原材料准备 | 采集纤维、检测质量 | 纤维采集设备、检测设备 | 该品牌采用先进的纤维检测设备,确保原材料的质量和纯度 |

| 机械加工 | 机械设备的介绍与操作流程 | 高速织布机、裁剪机、缝纫机等 | 该品牌采用先进的纺织机械,实现了高效、精确的加工 |

| 质量检测 | 质量检测设备与流程 | 光谱分析仪、X射线检测仪等 | 该品牌注重质量检测环节,采用了先进的检测设备和技术手段,确保产品质量符合标准要求 |

| 成功案例分析 | 通过案例展示成功经验和技术应用 | 该品牌在纺织品自动加工过程中取得了多项成功案例,如提高生产效率、降低生产成本等 | 通过案例分析,展示了纺织品自动加工过程中的成功经验和关键技术 |

通过这段视频解析和补充说明,我们深入了解了纺织品自动加工过程的全貌和关键环节,在未来的纺织品生产过程中,我们应该注重提高自动化水平,优化加工工艺和产品性能,提高生产效率和产品质量,我们也应该注重质量检测环节和技术创新,不断提高纺织品的品质和竞争力。

Articles related to the knowledge points of this article:

The Impediments of Limiting US Medical Textiles:A Comprehensive Analysis

Cost of Shipping Textiles from the United States to Singapore