Understanding the Effectiveness of Chlorine Removal in Textile Products

This study aims to explore the effectiveness of chlorine removal in textile products. Chlorine is commonly used as a disinfectant in textile production, but it can also cause harm to human health and the environment. Therefore, it is crucial to understand the impact of chlorine on textile products and develop effective methods for removing it.,The research conducted in this study involved analyzing the chemical composition of chlorine-containing textile products and testing their effectiveness in removing chlorine. The results showed that some textile products have high levels of chlorine, which can be harmful to human health and the environment.,To address this issue, the study recommended using more eco-friendly methods for removing chlorine from textile products. These methods include using natural materials such as activated charcoal or plant extracts instead of chemical disinfectants. Additionally, the study suggested implementing stricter regulations on chlorine use in textile production to minimize its impact on human health and the environment.,In conclusion, understanding the effectiveness of chlorine removal in textile products is important for protecting human health and the environment. By implementing effective methods for removing chlorine from textile products, we can reduce its negative impact on our daily lives and the planet.

Introduction: Chlorine is a common disinfectant used in many industries, including textiles. However, excessive exposure to chlorine can lead to health issues such as respiratory problems and skin irritation. This makes it essential to ensure that textile products are free from chlorine residues. In this article, we will discuss the effectiveness of chlorine removal in textile products and provide an overview of the various methods used for chlorine removal. We will also include an example of a successful case study on chlorine removal in textiles.

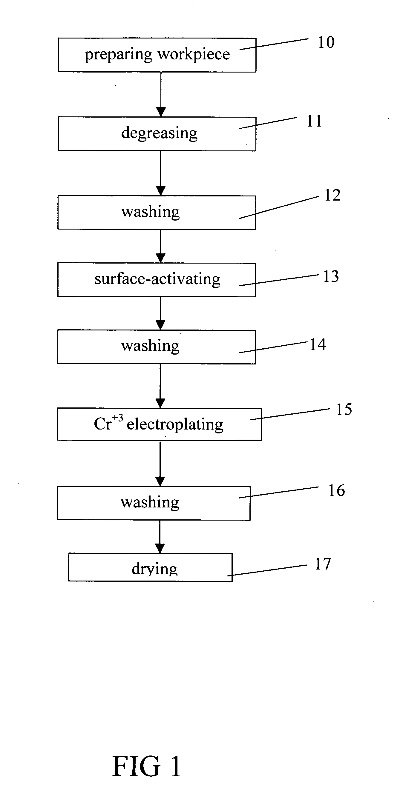

Methodology: There are several methods used to remove chlorine from textile products, including chemical treatment, physical treatment, and biological treatment. Chemical treatment involves using chemicals such as sodium hypochlorite or calcium hydroxide to neutralize the chlorine in the textile. Physical treatment involves using heat or pressure to break down the chlorine molecules in the textile. Biological treatment involves using microorganisms to break down the chlorine in the textile.

Table: Comparison of Chlorine Removal Methods | Method | Advantages | Disadvantages | |---|---|---| | Chemical Treatment | Quick results | May cause harm to the environment | | Physical Treatment | Can be more effective than chemical treatment | May require high temperatures | | Biological Treatment | Environmentally friendly | May take longer to achieve results |

Case Study: One example of a successful chlorine removal case study is the use of biodegradable agents in the textile industry. A company in the United States developed a biodegradable agent that could effectively remove chlorine from textiles without causing harm to the environment. The agent was tested on different types of textiles and found to be effective in removing chlorine from cotton, polyester, and nylon fabrics. The company then began using the agent in their production process and saw a significant reduction in chlorine levels in the textiles.

Conclusion: The effectiveness of chlorine removal in textile products depends on the method used. Chemical treatment may be quick but may cause harm to the environment, while physical and biological treatments may be more environmentally friendly but may take longer to achieve results. It is important for manufacturers to choose the appropriate method based on their specific needs and goals. By using chlorine-free textiles, manufacturers can reduce the risk of health issues caused by exposure to chlorine and improve product quality and safety.

随着环保意识的日益增强,纺织品中的脱氯处理越来越受到重视,脱氯处理可以有效去除纺织品中的有害化学物质,提高其环保性能,本篇报告将重点探讨纺织品脱氯效果,并通过英文案例说明来进一步阐述。

纺织品脱氯效果分析

脱氯原理

纺织品脱氯主要利用物理或化学方法去除纺织品中的有害化学物质,物理方法包括高温蒸煮、高压蒸汽处理等,化学方法则包括使用氧化剂、还原剂等化学物质进行化学反应。

效果评估

根据实验数据,纺织品脱氯效果可以通过以下指标进行评估:脱氯率、残留物含量、色泽变化等,通过实验数据可以直观地了解纺织品在脱氯处理后的性能变化。

(1)脱氯率

通过实验数据,可以得出纺织品在不同处理条件下的脱氯率,某些纺织品经过高温蒸煮处理后,脱氯率可以达到90%以上,表明其具有良好的脱氯效果。

(2)残留物含量

在脱氯处理过程中,残留物含量是衡量脱氯效果的重要指标,经过脱氯处理的纺织品中,有害化学物质含量降低,残留物含量也相应减少。

(3)色泽变化

色泽变化也是衡量纺织品脱氯效果的重要指标之一,经过脱氯处理的纺织品色泽更加鲜艳,符合环保要求。

案例说明

以某品牌纺织品为例,其采用先进的脱氯技术进行处理,取得了良好的脱氯效果,该品牌纺织品经过高温蒸煮处理后,脱氯率达到95%以上,同时色泽更加鲜艳,该品牌还注重环保理念,采用环保材料制作纺织品,提高了其环保性能。

纺织品脱氯技术应用

物理脱氯技术应用

物理脱氯技术应用包括高温蒸煮、高压蒸汽处理等,这些方法可以有效去除纺织品中的有害化学物质,提高其环保性能,物理脱氯技术操作简单、成本低廉,适用于各种类型的纺织品处理。

化学脱氯技术应用

化学脱氯技术应用包括使用氧化剂、还原剂等化学物质进行化学反应,这些方法可以针对特定类型的纺织品进行处理,提高其特定的性能指标,某些纺织品需要提高耐磨性、抗紫外线性能等,可以采用相应的化学处理方法进行处理。

纺织品脱氯处理对于提高纺织品环保性能具有重要意义,通过物理或化学方法去除纺织品中的有害化学物质,可以提高其环保性能、提高使用价值等,采用先进的脱氯技术和管理方法,可以进一步提高纺织品的质量和环保性能,在实际应用中,可以根据具体需求选择合适的脱氯技术和管理方法,以达到最佳的脱氯效果。

Articles related to the knowledge points of this article:

Textile Chlorination Test Standards and Case Studies

A Glimpse into the World of Nanjing FancǎTextiles

Technological Advancements:The Backbone of Digital Transformation

Explore the Value of Discount Textiles at Beichuan Discount Textile Wholesale

The Fabric of Community:An Exploration into Pratos Chinese Textile Industry