The Role of Quality Control in Textiles

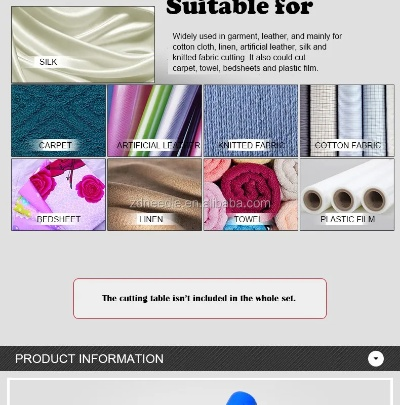

Quality Control plays a pivotal role in the production and quality assurance of textiles. It involves rigorous inspections, testing, and adjustments to ensure that the finished product meets industry standards and consumer expectations. This includes monitoring raw materials, processing steps, and final product quality to identify any defects or issues early on. Quality control also involves implementing quality management systems and using advanced technology to streamline the production process and improve efficiency. In addition to meeting regulatory requirements and ensuring product safety, effective quality control can help manufacturers build trust with customers, increase sales and market competitiveness. Overall, quality control is essential for ensuring textile products meet the high standards set by consumers and industry professionals alike.

Introduction: Quality control is crucial for the success of any manufacturing industry, including the textile sector. Textiles are among the most versatile and important materials used in our daily lives due to their durability, comfort, and aesthetic appeal. To maintain this high level of quality, rigorous quality control measures must be implemented throughout every stage of the production process, from raw material procurement to finished products. In this essay, we will explore the various methods and techniques used to ensure the quality of textile products.

Methodology: The quality control process in textiles involves a multi-tiered approach that includes testing before, during, and after the manufacturing process. Here's an overview of the steps involved:

-

Material Testing: Raw materials such as cotton, polyester, and wool are tested for quality before they enter the production line. This involves checking for defects, such as holes or fibers, and measuring its strength and consistency.

-

Process Testing: During the manufacturing process, samples of the final product are tested at regular intervals to ensure that each step meets specific standards. This includes checking thread count, fabric density, and color accuracy.

-

Finishing Process: After the fabric has been woven or knitted, it undergoes additional processing steps, such as dyeing, printing, or finishing. These steps are also tested for consistency and quality.

-

Packaging and Shipping: The final product is carefully packaged and shipped to the customer. It is crucial that the packaging protects the product against damage during transportation.

-

Customer Receipt: Upon receipt by the customer, the product is inspected for defects. If any issues are found, the manufacturer must resolve them immediately to prevent any further damage or harm to the customer.

Table 1: Textile Quality Testing Checklist

| Testing Phase | Method | Instrumentation | Result Criteria |

|---|---|---|---|

| Material Testing | Visual inspection | Saws, microscopes, calipers | No visible defects, consistent fiber size |

| Process Testing | Machinery monitoring | Sensors, cameras, thermometers | Stitch length, uniformity, temperature stability |

| Finishing Process | Hand inspection | Magnifying glasses, rulers | Color consistency, pattern matching, stitch accuracy |

| Packaging & Shipping | Packaging integrity | Inspection tags, weight checkers | Product integrity, no damage or loss |

| Customer Receipt | On-site inspection | Inspection tools, trained staff | No defective items received, correct return address |

Case Study: Consider the story of a textile company that produces clothing using a blend of synthetic and natural fibers. The company's quality control department was responsible for ensuring that every piece of clothing met stringent standards. One particularly challenging task involved ensuring the seamless weaving of the two types of fibers.

To tackle this challenge, the company invested in advanced machinery capable of precisely controlling the speed and tension of the weaving process. Additionally, regular training sessions were held for employees to understand the importance of maintaining consistent thread counts and patterns. By implementing these measures, the company was able to produce high-quality clothing that met or exceeded customer expectations.

Conclusion: Quality control is the backbone of any successful textile manufacturing operation. By employing a comprehensive approach that covers testing, processing, packaging, and customer satisfaction, manufacturers can deliver products that meet and even exceed industry standards. The case study illustrates how careful attention to detail and ongoing investment in technology and training can lead to improved quality, increased customer loyalty, and ultimately, long-term success in the competitive textile market.

在纺织品生产过程中,质量检验是确保产品符合标准、保证消费者权益的重要环节,本文将详细介绍纺织品质量的检验方法及案例分析,帮助大家更好地了解如何进行纺织品质量的检验。

纺织品质量检验方法

外观检验

外观检验是纺织品质量检验的基础环节,主要通过观察纺织品表面、质地、颜色等外观特征来判断其质量,具体包括以下几个方面:

(1)面料平整度:检查面料是否平整,有无褶皱、起毛等现象。

(2)颜色一致性:检查纺织品颜色是否一致,有无色差、色晕等现象。

(3)纤维含量检测:通过纤维含量检测仪器,对纺织品纤维含量进行准确测量。

机械性能检验

机械性能检验是检验纺织品强度、耐磨性、抗皱性等物理性能的重要手段,具体包括以下几个方面:

(1)强度测试:使用强力撕裂测试仪等设备,对纺织品进行强度测试,判断其抗拉强度、耐磨性等。

(2)耐磨性测试:通过模拟磨损环境,对纺织品进行耐磨性测试,评估其耐磨性能。

(3)抗皱性测试:使用抗皱性能测试仪等设备,对纺织品进行抗皱性能测试,观察其褶皱恢复情况。

化学成分检验

化学成分检验是通过检测纺织品中的化学成分来判断其成分是否符合标准,具体包括以下几个方面:

(1)纤维成分检测:通过纤维成分检测仪器,对纺织品中的纤维种类、含量等进行检测。

(2)染色牢度检验:通过染色牢度试验,检测纺织品染色后的耐久性和牢度。

实验室检测方法举例

实验室检测方法包括光谱分析、拉力测试、耐磨性试验等,光谱分析可以用于检测纺织品的纤维类型、含量等;拉力测试可以用于评估纺织品的抗拉强度和耐磨性能;耐磨性试验可以模拟实际使用环境,评估纺织品的耐磨性能。

案例分析

以某品牌纺织品为例,进行质量检验案例分析,该品牌在纺织品生产过程中,注重质量检验环节,确保产品质量符合标准,具体步骤如下:

-

外观检验:检查面料是否平整、有无褶皱、起毛等现象,经过外观检验,发现该品牌纺织品面料平整度良好,颜色一致,无明显色差和色晕现象,纤维含量检测也显示该品牌纺织品纤维含量符合标准。

-

机械性能检验:对该品牌纺织品进行强度测试和耐磨性测试,强度测试结果显示该品牌纺织品具有较高的抗拉强度和耐磨性能,符合标准要求,耐磨性试验中,该品牌纺织品表现优异,能够模拟实际使用环境中的磨损情况,表现出良好的耐磨性能。

-

化学成分检验:对该品牌纺织品进行化学成分检测,通过纤维成分检测仪器,发现该品牌纺织品的主要纤维种类为天然纤维,含量符合标准要求,染色牢度检验也显示该品牌纺织品染色后的耐久性和牢度良好。

总结与建议 可以看出,纺织品质量检验是一项重要的工作,需要采用多种方法进行全面检查,在具体操作中,需要注意细节和规范,确保检验结果的准确性和可靠性,还需要不断改进和完善质量检验方法和技术手段,提高纺织品质量水平,建议企业在生产过程中加强质量检验环节,确保产品质量符合标准要求,还需要加强质量管理体系建设,提高企业质量管理水平。

Articles related to the knowledge points of this article:

Exploring the Natural Elements of Liyun Textiles Raw Materials

The Complete Guide to Textile Dyeing Methods

Protecting Your Home with the Power of Antimicrobial Guangzhou Textiles