Detailed Guide to Exercise and Sports Textiles Processing

This detailed guide to exercise and sports textiles processing provides an in-depth overview of the manufacturing process, from raw materials to finished products. The guide covers topics such as fiber selection, spinning, weaving, knitting, and finishing techniques, as well as specific applications for various types of sports fabrics like athletic wear, gymnastics equipment, and outdoor gear.,The guide emphasizes the importance of quality control during the production process, including testing for strength, durability, and compliance with safety standards. It also discusses environmental factors that impact the production process, such as energy efficiency and waste reduction strategies.,Additionally, the guide highlights the benefits of using sustainable and eco-friendly materials in sports textiles, emphasizing the need for responsible sourcing and production practices. Overall, this guide provides a comprehensive understanding of the complexities involved in the production of high-quality sports textiles, and serves as a valuable resource for both industry professionals and students interested in the subject.

Introduction: Sports and exercise enthusiasts are always on the lookout for high-quality, durable sports textiles that can withstand the demands of their activities. The processing of these materials is a complex process that involves multiple stages, from raw material selection to final product inspection. In this guide, we will explore the various steps involved in the manufacturing process of sports and exercise textiles, including the importance of quality control and the latest technological advancements in the industry.

Raw Material Selection: The first step in the sports textiles processing chain is selecting the right raw materials. These materials must meet specific performance criteria such as strength, flexibility, and breathability. For example, polyester is commonly used for athletic wear due to its wicking properties, while cotton is preferred for clothing that requires comfort and breathability.

Preparation of Raw Materials: Once the raw materials are selected, they undergo a series of pretreatment processes to enhance their physical properties. This may include washing, dyeing, or finishing treatments. For example, cotton fabrics may be washed to remove any impurities and then dyed to achieve the desired color.

Weaving and Knitting: Once the raw materials are prepared, they are woven or knitted into the desired pattern. Weaving involves interlacing threads to create a fabric, while knitting involves looping threads together to form a closed structure. Both methods are crucial in creating the texture and pattern of the sports textiles.

Dyeing and Printing: After weaving or knitting, the textiles undergo dyeing or printing treatments to enhance their appearance and functionality. Dyers use different techniques such as pad printing, screen printing, or spray painting to apply colors onto the fabric.

Sizing and Stabilization: To ensure the durability and shape retention of the sports textiles, they are often treated with adhesives or other chemicals known as sizing or stabilization agents. These treatments help to bind the fibers together and prevent them from stretching or shrinking.

Finishing: Finally, the sports textiles undergo a series of finishing treatments to enhance their appearance and improve their performance. This may include additional dyeing, finishing treatments such as waxing or coating, or adding reinforcement materials such as spandex or elastane.

Quality Control: Quality control is essential in the sports textiles processing chain to ensure that the final product meets the required standards. This includes testing for strength and tear resistance, measuring for fit and comfort, and checking for any defects or irregularities.

Technological Advancements: In recent years, there have been significant technological advancements in the sports textiles processing industry. For example, the use of recycled materials has become increasingly popular, as it reduces waste and contributes to sustainability. Additionally, advancements in automation and robotics have allowed for more efficient and precise production processes.

Case Study: One example of a successful sports textiles processing company is Nike. Nike's commitment to excellence and innovation has led to the creation of some of the most iconic sportswear in history. From the revolutionary Air Force 1 sneaker to the innovative Flyknit technology used in their shoes, Nike has consistently pushed the boundaries of what is possible in sports textiles.

Conclusion: The sports textiles processing industry is constantly evolving, driven by advances in technology and consumer demand. By understanding the various steps involved in the manufacturing process and staying up-to-date with industry trends, manufacturers can produce high-quality products that meet the needs of athletes and consumers alike.

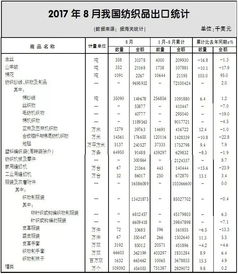

本表格详细介绍了运动纺织品加工的各个环节及其相关信息,包括原材料、工艺流程、设备配置、质量标准等,通过这份表格,我们可以更全面地了解运动纺织品加工的全过程。

原材料

运动面料

| 原材料名称 | 描述 | 来源地 | 品质要求 |

|---|---|---|---|

| 涤纶纤维 | 高强度、耐磨、抗皱等特性 | 国内外知名纺织企业供应 | 符合相关标准 |

| 氨纶纤维 | 弹性好、伸缩性好 | 国内外知名纤维供应商 | 符合相关标准 |

| 天然纤维 | 如棉、麻等 | 天然纤维产地 | 无毒环保,符合相关标准 |

| 其他辅助材料 | 如防滑剂、阻燃剂等 | 其他相关企业供应 | 根据实际需求确定 |

辅助材料

| 材料名称 | 用途 | 来源地或供应商 |

|---|---|---|

| 粘合剂 | 用于面料与织物的粘合 | 专业粘合剂生产厂家供应 |

| 缝纫线 | 用于缝合面料和织物 | 专业缝纫线生产厂家供应 |

工艺流程

原料准备

| 步骤名称 | 时间节点 | 主要设备或工具 |

|---|---|---|

| 材料检验 | 开始前进行,确保原材料质量合格 | 相关检测设备 |

| 混合与整理 | 根据工艺要求进行混合和整理,确保面料平整、无杂质 | 相关混合设备或整理机械 |

织造工艺流程

| 步骤名称 | 设备配置及操作方法 | 时间节点要求 | 质量标准 |

|---|---|---|---|

| 开幅与定型 | 开幅机、定型机等设备,根据织物厚度和密度进行定型处理 | 根据织物厚度和密度确定时间节点要求,确保织物平整、无褶皱、无纱线裸露等缺陷 | 根据织物类型和工艺要求确定质量标准,如达到特定厚度和密度要求等 |

| 针织工艺处理 | 根据织物类型选择针织工艺,如平纹、斜纹等,并进行相应的工艺处理,如起毛、起绒等操作步骤 | 根据工艺要求确定针织工艺处理时间节点和操作方法,确保织物性能达到预期要求 | 根据织物类型和工艺要求确定质量标准,如达到特定性能指标等 |

后处理工艺流程

| 步骤名称 | 设备配置及操作方法 | 时间节点要求 | 质量标准 |

|---|---|---|---|

| 烫平与定型处理 | 热烫机、熨斗等设备,根据面料材质和烫平需求进行烫平处理和定型处理,确保面料平整度达到预期要求 | 根据面料材质和烫平需求确定时间节点要求,确保面料达到特定平整度要求等 | 根据面料材质和烫印效果确定质量标准,如达到特定平整度和烫印效果等要求等,同时需注意环保和安全操作规范。 |

| 质量检测与整理包装 | 相关检测设备和整理包装设备,对加工后的产品进行质量检测和整理包装,确保产品符合相关标准和客户要求,同时需注意包装材料的环保和安全使用规范。 | 根据实际需求确定时间节点和操作方法,同时需注意包装材料的环保和安全使用规范,同时需注意记录和保存相关数据和信息。 | 根据实际需求确定质量标准,同时需注意记录和保存相关数据和信息,以便后续追溯和质量评估,同时需注意遵守相关法律法规和行业标准。 |

案例说明(以某运动纺织品加工企业为例)

某运动纺织品加工企业采用先进的生产工艺和技术,对运动面料进行精细加工,该企业的工艺流程主要包括原料准备、织造工艺流程和后处理工艺流程,具体案例如下:

- 原材料准备:该企业从国内外知名纺织企业和纤维供应商采购运动面料和相关辅助材料,确保原材料的质量符合相关标准和客户需求,该企业还注重环保和安全操作规范,使用环保型粘合剂和缝纫线等材料。

- 织造工艺流程:该企业在织造过程中采用了先进的织造工艺技术,包括开幅与定型、针织工艺处理等步骤,在开幅与定型过程中,该企业根据织物厚度和密度进行定型处理,确保织物平整、无褶皱、无纱线裸露等缺陷,针织工艺处理过程中,该企业根据织物类型选择合适的针织工艺,并进行相应的工艺处理,以获得更好的织物性能,在后期整理过程中,该企业注重产品的质量检测和整理包装,确保产品符合相关标准和客户要求,该企业还注重记录和保存相关数据和信息,以便后续追溯和质量评估。

- 后处理工艺流程:该企业在后处理过程中采用了烫平与定型处理步骤,使用热烫机等设备对面料进行烫平处理和定型处理,在烫平过程中,该企业严格控制温度和时间,以确保面料达到预期的平整度和烫印效果,该企业还注重包装材料的环保和安全使用规范,使用环保型包装材料进行包装,该企业还注重遵守相关法律法规和行业标准,确保生产过程符合相关法规要求。 通过该企业的案例说明,我们可以看到运动纺织品加工企业的生产工艺和技术水平得到了显著提升,该企业的生产过程注重环保和安全操作规范,符合相关法律法规和行业标准,该企业的产品质量也得到了客户的认可和好评。

Articles related to the knowledge points of this article:

The Evolutionary Journey of Dongguan Yushun Textiles Co.Ltd.