Strategies for Identifying Textile Risks

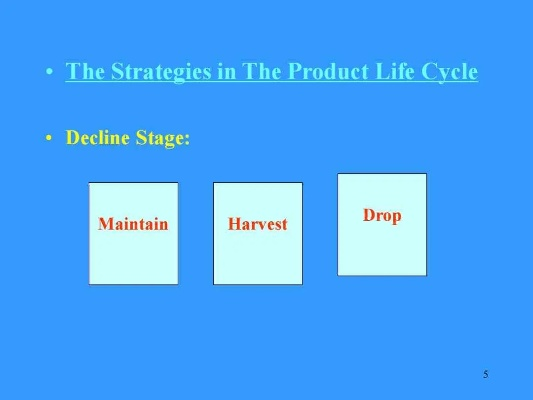

"Identifying textile risks is crucial for ensuring product quality, safety, and environmental protection. There are several strategies that can be employed to identify textile risks, including:,1. Conducting risk assessments: This involves analyzing the potential hazards associated with textile products, such as exposure to chemicals or allergens. Risk assessments can help identify potential risks and prioritize them accordingly.,2. Implementing quality control measures: Quality control measures can help identify any defects or issues in textile products before they reach the consumer. These measures may include testing for specific chemicals or allergens, as well as monitoring production processes.,3. Engaging in collaboration with industry experts: Collaborating with experts in the textile industry can provide valuable insights into potential risks and help develop effective strategies for identifying them.,4. Conducting regular inspections and audits: Regular inspections and audits can help identify any potential risks in textile products and ensure that they meet regulatory requirements.,Overall, identifying textile risks requires a multi-faceted approach that takes into account various factors, including product design, manufacturing processes, and regulatory requirements."

Introduction Textiles, as one of the most essential and versatile materials in our daily lives, are often used in various industries such as apparel, home furnishings, and industrial applications. However, with their wide range and diverse uses, textiles can pose a variety of risks that could impact both the quality and safety of end products. In this article, we will discuss some effective methods for identifying these risks and provide an example to illustrate how they can be applied.

Identification Methods

-

Material Analysis The first step in identifying textile risks is to analyze the raw materials used in the production process. This includes examining the composition of the fibers, dyes, and additives used. For example, certain types of dyes may cause skin irritation or allergies in sensitive individuals. Additionally, understanding the environmental impact of the raw materials used can help identify potential hazards associated with manufacturing processes.

-

Process Monitoring Regular monitoring of the manufacturing process is crucial for identifying any potential risks. This can involve using sensors and other equipment to track the temperature, pressure, and other variables that affect the quality and safety of the textiles produced. For instance, if the temperature during the dyeing process exceeds a certain limit, it may lead to uneven color distribution or chemical reactions that could damage the fabric.

-

Quality Control Quality control measures are essential for ensuring that the final product meets industry standards and consumer expectations. These measures include testing for defects such as thread breakage, fraying, and shrinkage. By conducting regular inspections and audits, manufacturers can identify any issues early on and take corrective action to prevent them from reaching the final product.

-

Regulatory Compliance Compliance with regulatory requirements is another important aspect of risk identification. Many countries have specific regulations governing the production and use of textiles, including those related to health and safety. Companies must ensure that their products meet all applicable standards and guidelines to avoid legal penalties and reputational damage.

-

Customer Feedback Customer feedback is also an important source of information for identifying risks in textile products. By collecting and analyzing customer complaints and reviews, companies can identify areas where their products may be lacking in quality or safety. This information can then be used to make improvements to products and processes to address these concerns.

Case Study: Bleached Knitwear Staining Issues In 2019, a major clothing manufacturer experienced a significant problem with its knitwear products after customers reported staining issues. The company had been using a new bleaching process to achieve brighter colors, but it was not entirely clear how well this process worked on different types of fabrics. As a result, some customers received products that were too dark or had discoloration that was not consistent across different batches.

To address this issue, the company conducted a thorough analysis of the raw materials used in the production process and monitored the manufacturing process closely to identify any potential risks. They also implemented stricter quality control measures, including regular inspections and audits, and required suppliers to provide detailed information about the materials used in their products.

In addition, the company collaborated with customers to gather feedback on their experiences with the products, which helped them understand the root causes of the staining issues and develop strategies to address them. As a result, the company was able to improve its production processes and reduce the occurrence of similar problems in the future.

Conclusion Identifying textile risks requires a combination of material analysis, process monitoring, quality control, regulatory compliance, and customer feedback. By implementing these strategies, companies can ensure that their products meet industry standards and consumer expectations while minimizing the risk of harm to consumers and the environment.

纺织品作为日常生活中不可或缺的原材料,其生产过程中的风险识别对于保障产品质量和消费者权益至关重要,本文将介绍纺织品风险识别的方法,并结合实际案例进行说明。

纺织品风险识别方法

风险识别流程

(1)收集信息:通过市场调研、行业报告、技术文献等方式,收集纺织品生产过程中的各种风险信息。

(2)分析原因:对收集到的风险信息进行深入分析,找出可能的原因。

(3)确定风险等级:根据风险可能性和影响程度,确定风险的等级。

(4)制定应对策略:根据风险等级,制定相应的应对策略。

常用风险识别方法

(1)定性风险识别法:通过专家评估、历史数据对比等方式,对纺织品生产过程中的风险进行定性分析。

(2)定量风险识别法:利用数学模型、统计分析等方法,对纺织品生产过程中的风险进行定量分析。

案例说明

以某纺织企业为例,该企业在生产过程中面临的主要风险包括原料质量不稳定、生产环境恶劣、技术更新滞后等,针对这些风险,企业采取了以下应对策略:加强原料质量控制,改善生产环境,及时更新技术设备,企业还建立了风险监测系统,对生产过程中的风险进行实时监测和预警。

纺织品风险识别案例分析

原料质量不稳定风险识别案例分析

(1)收集信息:该企业采购的原料主要来自外部市场,存在原料质量不稳定的风险,通过市场调研发现,部分原料质量不符合标准。

(2)分析原因:原料质量不稳定的原因可能包括供应商管理不善、原料采购不严格等。

(3)确定风险等级:根据风险可能性和影响程度,该企业认为原料质量不稳定的风险属于中等级别。

(4)制定应对策略:企业加强与供应商的沟通与合作,建立严格的原料质量控制体系;加强原料检测,确保原料质量符合标准。

生产环境恶劣风险识别案例分析

(1)收集信息:该企业在生产过程中面临的生产环境恶劣,包括高温、高湿、噪音等不利因素。

(2)分析原因:生产环境恶劣的原因可能包括设备老化、管理不善等。

(3)制定应对策略:企业采取改善生产环境措施,如加强设备维护、优化生产工艺等;建立环境监测系统,实时监测生产环境情况。

纺织品风险防范措施

加强原料质量控制

(1)建立原料质量控制体系,明确原料采购、检验、存储等环节的规范要求。

(2)加强原料检测,确保原料质量符合标准。

(3)建立原料信息共享机制,及时了解市场原料质量情况。

改善生产环境

(1)加强设备维护,确保生产设备处于良好状态。

(2)优化生产工艺,提高生产效率和质量。

(3)建立环保意识,推广绿色生产方式。

技术更新滞后风险防范措施

(1)加强技术研发和创新能力,及时更新技术设备。

(2)建立技术更新机制,鼓励企业采用新技术、新工艺。

(3)加强人才培养,提高企业技术创新能力。

总结与展望

纺织品风险识别是保障产品质量和消费者权益的重要环节,本文介绍了纺织品风险识别的方法和案例分析,同时提出了纺织品风险防范措施,随着纺织行业技术的不断进步和消费者需求的不断提高,纺织品生产过程中的风险也将不断变化和升级,企业需要不断加强风险管理意识,完善风险管理机制,提高风险管理水平。

Articles related to the knowledge points of this article:

Exploring the Ten Top Textiles of Stone Lions An Illustrative Journey