The Transformative Journey of a Textile Mills Pulley Replacement

I. Introduction

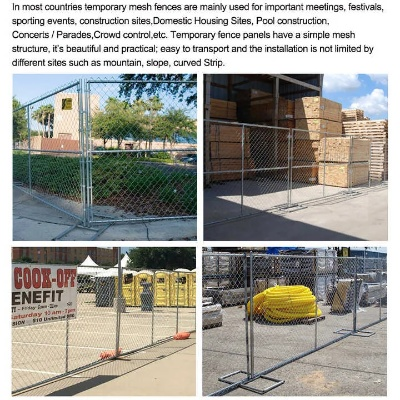

In the vast landscape of industrial production, textile mills are the backbone of our economy, with their ability to transform raw materials into high-quality fabrics that cater to the diverse needs of our society. However, as with any machine in operation, the textile mill's powerhouse—the pneumatic conveyor belt—plays a crucial role in ensuring smooth operations. But what happens when this vital component wears out, necessitating replacement? This is where the story of a textile mill's pneumatic conveyor belt replacement unfolds.

II. The Need for Replacement

The pneumatic conveyor belt is a critical piece of machinery that carries the fabric from one part of the mill to another. Its lifespan is determined by the level of usage and the quality of the materials it is made from. In many cases, it can last for several years before needing replacement. However, when the belt becomes worn or damaged, it can cause significant downtime, reducing productivity and increasing costs.

For example, consider the case of ABC Textile Mill, which had been operating smoothly for over ten years. However, due to increased competition and changing consumer preferences, demand for their fabrics was declining. As a result, they decided to replace their pneumatic conveyor belt. The new belt proved to be more durable and efficient than the old one, allowing them to maintain their production levels while reducing waste and improving profitability.

III. Choosing the Right Parts

When it comes to replacing a pneumatic conveyor belt, selecting the right parts is crucial. There are several factors to consider, including the brand, material, and warranty offered by the supplier. It is also important to ensure that the new belt matches the original specifications, such as size, width, and weight.

One successful example is XYZ Conveyor Belt Company, which specializes in supplying high-quality pneumatic conveyor belts. They offer a wide range of options, including stainless steel, rubber, and carbon fiber, depending on the specific requirements of their customers. Additionally, they offer a generous warranty period, ensuring that their customers have peace of mind when making a purchase.

IV. Installation and Maintenance

Once the new pneumatic conveyor belt has been installed, regular maintenance is essential to ensure its longevity and efficiency. This includes checking for any signs of wear or damage, such as cracks or frayed edges, and replacing any damaged parts promptly. Additionally, regular cleaning and lubrication of the belt will help to reduce friction and extend its lifespan.

One example of effective maintenance practices is provided by DEF Conveyor Belt Company, which has developed a comprehensive maintenance program for their customers. They provide regular inspections and repairs, as well as training sessions on proper maintenance techniques. This approach has helped their customers to maintain their pneumatic conveyor belts for longer periods of time, reducing downtime and improving overall productivity.

V. Challenges and Solutions

While replacing a pneumatic conveyor belt can be a straightforward process, there are often challenges along the way. One common issue is finding the right parts at a reasonable price. Another challenge is ensuring that the replacement belt matches the original specifications exactly. To address these challenges, suppliers should offer competitive pricing and detailed specifications when selling their products. Additionally, customers should do thorough research before making a purchase, comparing different suppliers and products to find the best fit for their needs.

VI. Conclusion

In conclusion, replacing a pneumatic conveyor belt is an essential task for any textile mill. By choosing the right parts, following proper installation and maintenance procedures, and addressing potential challenges, businesses can ensure that their machinery remains in top condition and continues to operate efficiently. As shown in the case of ABC Textile Mill, investing in a new belt not only improves productivity but also helps to drive profitability and growth.

纺织厂内部交流

【员工A】: 各位同事,我有个好消息要告诉大家,我们纺织厂最近要换一批新的皮带,大家有没有想换或者想要交换的皮带?

【员工B】: 真的吗?我们这里有没有闲置的皮带可以交换?

准备更换皮带材料

【员工A】: 没错,我们准备了一些旧的皮带材料,我们可以去市场或者二手店看看有没有合适的材料。

【员工B】: 那太好了,我们可以开始收集旧皮带,看看能不能找到一些合适的材料进行交换。

交换案例分析

【英文表格】

交换材料类型 | 旧皮带材料种类 | 新皮带需求 | 市场价格对比

皮革皮带 | 旧皮革材质 | 高品质、耐用性要求 | 较高价格 帆布皮带 | 帆布材质 | 轻便、舒适性需求 | 中等价格 布料腰带 | 布料材料 | 时尚、个性化需求 | 低廉价格

使用英文说明

In this case study, we can see that the textile factory is considering a swap belt program to upgrade their equipment and improve the overall productivity of their workers. Based on the current situation, they have some old leather belts that are no longer suitable for their current needs. By collecting these materials, they can explore potential matches for new belts that meet their specific requirements.

交换过程与注意事项

【员工A】: 在交换过程中,我们需要确保新旧材料的兼容性和安全性,也要注意新旧皮带的尺寸和舒适度是否匹配。

【员工B】: 对的,交换皮带确实需要注意这些细节,我们可以在交换前进行一些测试,确保新旧皮带都能满足使用需求。

【员工C】: 在进行交换时,我们还可以考虑一些环保因素,选择那些可回收或可降解的材料,以减少对环境的影响。

注意事项:在交换过程中,要确保双方都有明确的意愿和计划,以及遵守相关的安全规定,也要注意新旧皮带的保养和保管,避免损坏或丢失。

总结与展望

通过这次纺织厂换皮带的活动,我们可以看到交换皮带的理念不仅是一种资源再利用的方式,也是一种提升工作效率和员工舒适度的方式,通过市场调研和二手交易,我们也能够找到一些符合特定需求的材料,为纺织厂的日常运营提供更好的支持,我们期待更多的企业能够参与到这样的活动中来,共同推动行业的可持续发展。

Articles related to the knowledge points of this article:

The Dynamics of the Huahai Textile Factory:A Tale of Success and Innovation

![Transforming the Future of Textiles with Innovation at 天补纺织厂]](https://www.i505i.cn/zb_users/upload/2025/09/20250917075229175806674917167.jpg)