Ensuring Quality in Changning District Textiles

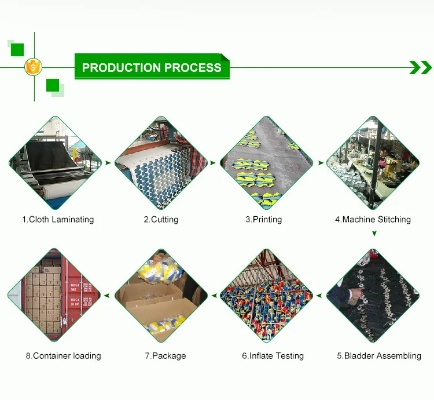

: Ensuring Quality in Changning District Textiles,Changning District, located in the southern part of China's Guangdong Province, is renowned for its textile industry, producing a wide range of high-quality garments and accessories. The district's textile sector has been instrumental in promoting local employment and generating significant economic growth. However, maintaining the quality of its products remains a critical challenge that requires concerted efforts from various stakeholders. This paper explores the strategies employed by the Changning District government to ensure quality in its textile industry.,One approach is through the establishment of a comprehensive quality control system, which includes regular inspections, certification programs, and training for textile workers. Additionally, the district has implemented strict environmental regulations to minimize the impact of pollution on the quality of its textile products.,Another strategy is to leverage technology, particularly in the areas of automation and digitalization, which can enhance efficiency and precision in the production process. By adopting advanced manufacturing techniques, the district aims to improve product consistency and reduce waste.,Furthermore, the district has established a strong supply chain management system, ensuring that raw materials are sourced only from reliable suppliers and that finished products meet international standards. Consumer education campaigns also play a crucial role in raising awareness about the importance of quality in the textile industry and encouraging consumers to choose products with good quality assurance.,In conclusion, ensuring quality in Changning District textiles is a multifaceted endeavor that involves implementing stringent quality control measures, leveraging technological advancements, managing the supply chain effectively, and engaging with consumers to foster a culture of quality. By working together, the district can continue to produce high-quality textile products that meet global standards and contribute to its ongoing economic growth.

Quality assurance is a critical aspect of any industry, and for the textile industry, it's even more vital. In Changning District, where textile products are produced and sold, ensuring quality is paramount to maintaining consumer trust and ensuring long-term success for businesses. This article will discuss the measures taken by the Changning District government and private sector organizations to guarantee the quality of textiles in the district.

Government Measures

The Changning District government has implemented several measures to ensure the quality of textiles in the district. One such measure is the establishment of a Quality Control Bureau, which is responsible for monitoring and enforcing standards for textile products. The bureau conducts regular inspections of factories and warehouses to ensure that they meet the required standards. Additionally, the bureau provides training and education to manufacturers on best practices for quality control.

Another measure is the implementation of strict regulations on imported textile products. The government requires all imported textiles to undergo rigorous testing before being allowed to enter the market. This ensures that only high-quality products are available for consumers in the district.

Private Sector Measures

While the government plays a crucial role in ensuring quality, the private sector also takes responsibility for its own actions. Many companies have implemented measures to ensure the quality of their products. For example, some companies use advanced technology to monitor the production process and identify any potential issues early on. Others use strict quality control procedures to ensure that every product meets the required standards.

One such company is Xinjiang Textile Co. Ltd., which produces high-quality cotton fabrics. The company employs a team of experts who regularly inspect its factories to ensure that they meet the required standards. Additionally, Xinjiang Textile Co. Ltd. has established a quality control system that involves regular audits and tests to ensure that every product meets the required standards.

Case Study: Xinjiang Textile Co. Ltd.

Xinjiang Textile Co. Ltd. is a leading manufacturer of cotton fabrics in Changning District. To ensure the quality of its products, the company has implemented several measures. Firstly, the company uses advanced technology to monitor the production process and identify any potential issues early on. This allows the company to take corrective action before the product leaves the factory. Secondly, the company has established a quality control system that involves regular audits and tests to ensure that every product meets the required standards.

In addition to these measures, Xinjiang Textile Co. Ltd. has also invested in employee training to ensure that everyone involved in the production process understands the importance of quality control. This not only helps to improve the quality of the products but also ensures that employees are motivated to work towards achieving high-quality results.

Importance of Quality Assurance

Quality assurance is essential for any industry, including the textile industry. By implementing measures such as the Quality Control Bureau, strict regulations on imported textiles, and advanced technology, the Changning District government and private sector organizations can ensure that the quality of textiles in the district is up to standard.

Moreover, investing in employee training and establishing a quality control system can further enhance the quality of products produced in the district. By doing so, businesses can build trust with consumers and maintain their position in the competitive textile market.

In conclusion, ensuring quality in the textile industry is crucial for maintaining consumer trust and ensuring long-term success for businesses in Changning District. Through government measures, private sector initiatives, and advanced technology, businesses can implement measures to ensure the quality of their products and build a reputation for excellence in the industry.

长宁区作为上海市的重要区域,其纺织品质量对于保障消费者权益、维护市场秩序具有重要意义,本篇旨在探讨长宁区纺织品质量保障的策略与实践,并通过案例分析来进一步说明。

纺织品质量保障的重要性

纺织品作为日常生活必需品,其质量直接关系到消费者的使用体验和身体健康,在长宁区,纺织品质量保障主要涉及以下几个方面:

- 源头质量控制:从原材料采购到生产过程控制,严格把控质量标准,确保原材料符合国家标准。

- 质量检测与认证:建立完善的检测体系,对纺织品进行严格的质量检测,确保产品符合相关标准和认证要求。

- 消费者教育:加强消费者对纺织品质量的认识和了解,提高消费者的维权意识。

长宁区纺织品质量保障策略

- 政策支持与法规制定:政府出台相关政策,鼓励纺织品生产企业加强质量管控,同时制定严格的法规标准,确保纺织品质量符合要求。

- 质量检测与认证体系完善:建立多层次的检测认证体系,包括第三方检测机构、行业协会等,对纺织品进行全方位的质量检测和认证。

- 强化供应链管理:加强与供应商的合作,建立严格的供应商准入制度,确保供应链的稳定性和可靠性。

- 消费者教育普及:开展多种形式的消费者教育活动,提高消费者对纺织品质量的认识和了解,举办纺织品质量知识讲座、消费者体验活动等。

案例分析

以某知名纺织企业为例,该企业在长宁区具有较高的知名度,其纺织品质量得到了广大消费者的认可,该企业在纺织品质量保障方面采取了以下措施:

- 源头质量控制:该企业从源头抓起,严格控制原材料采购质量,确保原材料符合国家标准,建立严格的原材料检验制度,对每一批次的原材料进行严格把关。

- 质量检测与认证:该企业建立了完善的检测体系,包括实验室检测、在线监测等多种检测方式,积极申请相关认证,确保产品符合国内外相关标准和认证要求。

- 消费者教育:该企业注重消费者教育,通过多种形式的活动提高消费者对纺织品质量的认识和了解,定期发布纺织品质量报告、举办消费者体验活动等,该企业还与行业协会合作,开展纺织品质量培训课程,提高消费者的维权意识。

长宁区纺织品质量保障需要从政策支持、质量检测与认证体系完善、供应链管理以及消费者教育等多个方面入手,通过实施这些策略和措施,可以有效提高纺织品质量水平,保障消费者的权益和健康,企业也需要不断改进和创新,提高纺织品的质量和竞争力。

Articles related to the knowledge points of this article:

Breaking Barriers and Unleashing Potential at the Frankfurt Textile Expo

The Advantages of Textiles Over Plastic Films in Various Applications