The Fabric Fiasco:Unraveling the Causes and Solutions of Textile Defects

"The Fabric Fiasco: Unraveling the Causes and Solutions of Textile Defects",This article explores the complex issue of textile defects, highlighting the various causes that contribute to these issues. The article discusses the importance of proper manufacturing processes, quality control measures, and the role of advanced technology in reducing fabric defects. It also provides insights into the solutions that can be implemented to address these issues, such as implementing stricter standards for product inspection, investing in research and development to improve materials and manufacturing techniques, and providing ongoing training and education to employees on best practices for textile production. Overall, this article aims to provide a comprehensive understanding of the causes and solutions to textile defects, and to encourage industry professionals to take proactive steps to prevent and mitigate these issues.

Introduction: The textile industry is a cornerstone of our daily lives, from the softness of our favorite sweaters to the durability of our work uniforms. However, when these fabrics fail to meet our expectations, it can lead to frustration and potential health hazards. In this article, we will explore the causes of textile defects and offer practical solutions to minimize such incidents. Let's dive into the world of textiles and uncover the truth behind those unsightly stains.

Table of Contents:

-

Understanding Textile Defects

-

Common Causes of Textile Defects

-

Preventive Measures

-

Corrective Strategies

-

Case Studies

-

Conclusion

-

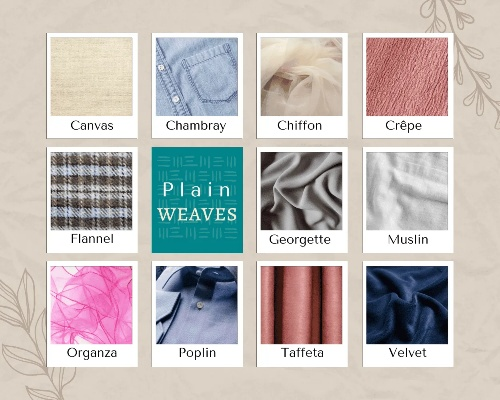

Understanding Textile Defects Textile defects refer to any imperfections in the fabric that affect its appearance, functionality, or comfort. These defects can range from minor blemishes like loose fibers or small holes to more significant issues like color fading, pilling, or excessive pilling. The severity of the defect often determines how quickly it needs to be addressed.

-

Common Causes of Textile Defects There are several common reasons for textile defects, including:

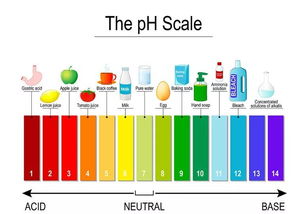

- Dyeing Issues: Incorrect dyeing techniques can cause discoloration, fade, or spotting.

- Weaving Mistakes: Errors during the weaving process can result in loose fibers or thread breaks.

- Pressing Improperly: Overpressing can cause fabric to shrink or become too stiff.

- Chemical Treatments: Excessive use of chemicals can damage the fabric structure.

- Machine Maintenance: Regular maintenance of the machinery used in the production process is essential for preventing defects.

- Material Quality: Low-quality materials may not withstand the manufacturing process and lead to defects.

Preventive Measures To prevent textile defects, manufacturers should adhere to strict quality control standards and implement preventative measures at every stage of the production process. This includes:

- Quality Assurance Testing: Conducting regular inspections to identify defects before they become visible.

- Adequate Material Handling: Proper storage and handling of raw materials and finished products can help prevent contamination and damage.

- Professional Machinery Maintenance: Regularly inspecting and maintaining machinery can reduce the risk of machine failure leading to defects.

- Training Workforce: Educating employees on proper techniques and procedures can help minimize errors during production.

- Environmental Control: Ensuring a clean and controlled work environment can prevent contaminants from entering the production process.

Corrective Strategies If textile defects do occur, there are several corrective strategies to address them effectively:

- Patchwork: For minor flaws, patches can be applied to the affected area using a similar fabric.

- Repair: For larger defects, repairing the damaged area can restore the fabric's integrity.

- Removal: For severe defects, the fabric may need to be removed and replaced with new material.

- Sizing Adjustments: If the defect is due to incorrect sizing, re-sizing the fabric can fix the issue.

- Customization: For unique designs, customization allows for individualized repairs or replacements.

Case Studies To illustrate the impact of textile defects and how they can be addressed, consider the following case studies:

- Case Study 1: A company experienced a significant drop in sales after a batch of clothing was recalled due to poor dyeing quality. The manufacturer implemented a comprehensive quality control system and increased training for their workforce, resulting in a significant improvement in product quality and customer satisfaction.

- Case Study 2: A garment manufacturer discovered that their washing machines were causing excessive pilling on some fabrics. They replaced the machines with new models equipped with advanced anti-pilling technology, which significantly reduced the incidence of pilling on subsequent batches.

Conclusion Textile defects can have serious consequences for manufacturers and consumers alike. By understanding the causes and implementing preventive and corrective measures, businesses can minimize the occurrence of these issues. It is essential for manufacturers to prioritize quality control and invest in the latest technology and training to ensure that their products meet the highest standards of excellence. With careful attention to detail and a commitment to excellence, textile manufacturers can provide customers with reliable, durable, and aesthetically pleasing products that exceed their expectations.

纺织品掉渣现象概述

在日常生活中,我们常常会遇到纺织品在使用过程中出现掉渣的问题,这不仅影响了产品的美观度,还可能给穿着者带来不适,纺织品掉渣可能是由于多种原因造成的,包括纤维材质、生产工艺、使用环境等,本文将通过案例分析和讨论,深入探讨纺织品掉渣现象及其解决方案。

纺织品掉渣案例分析

某品牌女士连衣裙

某品牌女士连衣裙在销售过程中出现掉渣问题,该连衣裙采用高质量的纤维材质,但经过一段时间的使用后,出现了明显的掉渣现象,消费者反映,穿着时感觉衣物不平整,影响了穿着体验。

分析:纺织品掉渣的原因可能包括纤维材质本身的问题,如纤维结构不稳定、纤维表面处理不当等,生产工艺也可能存在问题,如纺丝过程中的温度控制不当、纤维干燥不均匀等,使用环境也可能对纺织品造成影响,如潮湿、摩擦等。

改进措施

针对纺织品掉渣问题,该品牌采取了一系列改进措施,加强原材料质量控制,选用高质量的纤维材质,确保纤维结构稳定、表面处理得当,优化生产工艺流程,提高纺丝过程中的温度控制、纤维干燥均匀性等,加强产品使用环境的控制,避免在潮湿、摩擦等环境下使用。

纺织品掉渣现象的英文表格说明

以下是对纺织品掉渣现象的英文表格说明:

| 指标 | 描述 | 例子 | 解决方案 |

|---|---|---|---|

| 纤维材质 | 材质问题 | 采用高质量纤维材质 | 加强原材料质量控制 |

| 生产工艺 | 生产问题 | 生产工艺不当 | 优化生产工艺流程 |

| 使用环境 | 使用环境影响 | 使用潮湿、摩擦等环境 | 加强产品使用环境的控制 |

纺织品掉渣问题的解决方案

针对纺织品掉渣问题,我们可以采取以下解决方案:

- 加强原材料质量控制:选用高质量的纤维材质,确保纤维结构稳定、表面处理得当,对原材料进行严格检测,避免使用劣质材料。

- 优化生产工艺流程:提高纺丝过程中的温度控制、纤维干燥均匀性等,确保纤维在生产过程中的质量稳定,加强工艺培训,提高员工对生产工艺的掌握程度。

- 加强产品使用环境的控制:避免在潮湿、摩擦等环境下使用纺织品,加强产品包装和存储管理,确保产品在运输和使用过程中不受损害。

纺织品掉渣现象是一个比较普遍的问题,它不仅影响了产品的美观度,还可能给穿着者带来不适,针对纺织品掉渣现象,我们应该采取相应的解决方案,加强原材料质量控制、优化生产工艺流程、加强产品使用环境的控制等,我们还可以通过加强宣传和教育,提高消费者对纺织品质量的认识和要求。

Articles related to the knowledge points of this article:

The Impact of the US Export Textile Tax on Global Trade