Transforming the Future of Textiles:The Story of Changping Textile Factory

The Changping Textile Factory, located in the heart of China's textile industry, stands as a symbol of innovation and resilience. Since its inception in 1958, the factory has undergone numerous transformations, from humble beginnings to becoming a global leader in the production of high-quality textile products.,Over the years, the Changping Textile Factory has embraced technological advancements, investing heavily in research and development to create new materials and processes. This has led to a significant increase in product quality, reducing waste and improving efficiency.,In addition to technological innovation, the factory has also focused on sustainable practices. By adopting eco-friendly methods and reducing its carbon footprint, the factory has become a role model for other textile manufacturers.,Today, the Changping Textile Factory continues to play an integral role in Chinese textile production. With its commitment to innovation and sustainability, it is poised to continue shaping the future of textiles for generations to come.

Introduction: In the world of textiles, Changping Textile Factory stands out as a beacon of innovation and commitment to sustainability. Established over a century ago, this factory has not only revolutionized the production of high-quality fabrics but also played a pivotal role in advancing the industry's future through sustainable practices. This journey is a testament to the power of collaboration, technology, and dedication towards creating a better world for tomorrow.

Partnerships: Changping Textile Factory's journey began with a visionary partnership between the factory's founder and renowned textile designer, Mr. Li Qiang. Together, they recognized the potential of using advanced technology to enhance the quality of fabrics and create more eco-friendly processes. This partnership led to the establishment of a research center that focuses on developing new materials and techniques that are both efficient and environmentally friendly.

Case Study: To illustrate the success of this partnership, let us take a closer look at the development of a new yarn blend that uses biodegradable materials. Through rigorous testing and refinement, the blend has been found to significantly reduce waste while maintaining the same level of strength and durability. By implementing this new material into their production process, Changping Textile Factory has not only reduced its carbon footprint but also increased its market competitiveness.

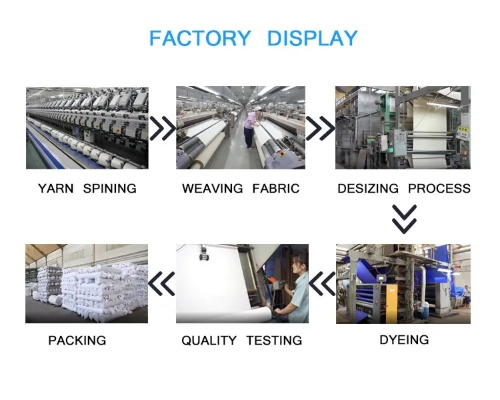

Technology Advancements: As technology continues to evolve at an unprecedented pace, Changping Textile Factory has been at the forefront of adopting cutting-edge technologies. One notable example is their use of 3D printing technology to produce custom-sized fabrics, reducing waste and increasing efficiency. Additionally, the factory has invested in renewable energy sources such as solar panels and wind turbines, further reducing its reliance on fossil fuels.

Sustainability Goals: Changping Textile Factory is not just focused on technological advancements; it also prioritizes sustainability. The factory has set ambitious goals to reduce its overall environmental impact by 20% over the next five years. This includes investing in recycling programs, implementing water and energy-saving measures, and reducing the use of harmful chemicals in its production process. Through these efforts, Changping Textile Factory is setting a benchmark for other textile manufacturers to follow.

Future Prospects: Looking to the future, Changping Textile Factory is committed to staying at the forefront of innovation. The factory plans to invest in AI-powered machinery that will automate certain production processes and improve accuracy, resulting in faster turnaround times and higher quality products. Additionally, the company is exploring new areas such as smart textiles and wearable technology, where digital fabrics can monitor health or adjust temperature based on user preferences.

Conclusion: Changping Textile Factory's story is one of progress and transformation. By partnering with visionaries, embracing technology, and prioritizing sustainability, the factory has not only transformed itself but also set an example for others in the industry to follow. As we enter a new era of textile manufacturing, Changping Textile Factory's commitment to innovation, sustainability, and customer satisfaction will undoubtedly continue to drive change and shape the future of textiles.

背景介绍

长平纺织厂位于我国某地区,是一家历史悠久的纺织企业,该厂以其精湛的工艺、优质的产品和良好的信誉在当地享有盛誉,近年来,随着市场竞争的加剧,长平纺织厂不断进行技术创新和产业升级,力求在激烈的市场竞争中保持领先地位。

长平纺织厂的发展历程

早期发展阶段

在过去的几十年里,长平纺织厂经历了从手工制作到机械化生产的转变,他们注重技术创新和人才培养,不断提高生产效率和产品质量。

现代化生产流程

近年来,长平纺织厂引入了先进的生产设备和技术,实现了自动化、智能化生产,他们注重环保和可持续发展,采用环保材料和节能技术,降低生产成本,提高资源利用效率。

长平纺织厂的产品与服务

长平纺织厂的产品种类繁多,包括棉布、丝绸、麻布等各类纺织品,他们的产品以其高质量、高性价比、多样化的特点赢得了广大消费者的喜爱,长平纺织厂还提供定制化服务,满足客户的不同需求。

案例分析

为了更好地说明长平纺织厂的发展情况,我们可以引用一个具体的英文案例。

环保纺织品生产项目

某地区的一家长平纺织厂成功实施了一项环保纺织品生产项目,他们采用环保材料和技术,降低生产成本,提高资源利用效率,他们注重产品质量和客户体验,提供优质的售后服务,该项目不仅提高了企业的经济效益,也赢得了广大消费者的好评。

技术创新与产业升级

长平纺织厂在技术创新和产业升级方面取得了显著成果,他们注重技术研发和创新人才的培养,不断提高生产效率和产品质量,他们还积极引进先进的生产设备和技术,实现自动化、智能化生产,长平纺织厂还注重绿色环保和可持续发展,推动产业升级和转型。

展望未来,长平纺织厂将继续加强技术创新和产业升级,提高生产效率和产品质量,他们还将注重品牌建设和市场营销,提高企业的知名度和美誉度,他们还将积极拓展国际市场,提高企业的国际竞争力。

长平纺织厂是一家历史悠久、技术精湛、产品优质的企业,他们在技术创新和产业升级方面取得了显著成果,为当地经济发展做出了重要贡献,长平纺织厂将继续加强品牌建设和市场营销,提高企业的竞争力和影响力。

Articles related to the knowledge points of this article:

Exploring the Industrial Splendor of Jiangsus Spring Scenery Textile Factory

The Story of the Tianfu Textile Factory