Textile Oxygen Index Method and Its Application in Fire Safety

The Textile Oxygen Index Method (TOIM) is a critical tool for assessing the combustibility of textiles. This method involves measuring the oxygen index, which is defined as the ratio of oxygen to fuel needed to initiate and sustain a flame. The TOIM provides a quantitative measure of the fire safety properties of textile materials, enabling manufacturers to optimize their products for use in hazardous environments. In this context, we explore the application of the TOIM in fire safety assessments, highlighting its importance in ensuring that textiles meet stringent safety standards. By understanding the principles behind the TOIM and how it can be used to evaluate the fire resistance of various textile products, we aim to promote safer and more effective fire protection measures.

Introduction to Textile Oxygen Index Method (TOI)

The textile industry is a critical component of our daily lives, from clothing to furnishings. However, this sector is also prone to fire hazards due to the high levels of combustible materials used in its production. The Textile Oxygen Index Method (TOI) is a widely recognized standard that evaluates the resistance of textile products to ignition and combustion under specific conditions. This method is essential for ensuring the safety of consumers and preventing potential fire incidents.

Textile Oxygen Index Method Overview

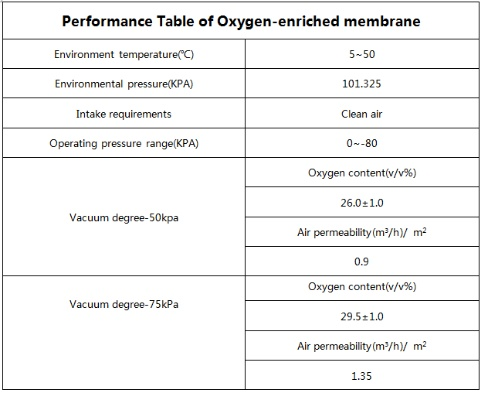

The Textile Oxygen Index Method (TOI) is a test that measures the amount of oxygen required to ignite a textile sample. It is based on the principle that combustion occurs when there is an imbalance between the concentration of oxygen and the concentration of fuel. In the case of textiles, this means that if the oxygen level in the air is too low, the textile will not ignite. Conversely, if the oxygen level is too high, the textile will burn more intensely.

To determine the TOI, a sample of the textile is exposed to an oxygen-enriched environment while being monitored for any signs of ignition. The time it takes for the sample to ignite is recorded, along with the temperature at which it does so. These data are then used to calculate the TOI value, which represents the minimum oxygen concentration required to ignite the textile.

Application of Textile Oxygen Index Method

The Textile Oxygen Index Method (TOI) has several applications in the textile industry. One of the most significant uses is in assessing the fire safety performance of textile products. By using the TOI, manufacturers can identify areas where their products may be vulnerable to fire hazards and take steps to address these risks.

Another important application is in regulatory compliance. Many countries have set standards for the TOI values of textiles, requiring manufacturers to meet certain requirements. Companies that fail to comply risk fines or even recall of their products. Therefore, understanding and implementing the TOI is crucial for maintaining compliance with regulations.

In addition, the Textile Oxygen Index Method (TOI) can be used to optimize the design of textile products. By understanding the impact of different factors on the TOI, designers can create textiles that are more resistant to fire. For example, incorporating flame retardant additives into the fabric can increase its TOI value and make it more resistant to fire.

Case Study: Textile Oxygen Index Method in a Real-World Scenario

One example of how the Textile Oxygen Index Method (TOI) can be applied in a real-world scenario is in the development of fire-resistant clothing. A company producing outdoor clothing sought to improve its product's fire safety performance. They tested various fabrics and found that a blend of polyester and cotton had the best combination of properties for fire protection.

Using the TOI, they determined that this particular fabric needed a minimum oxygen concentration of 18% to ignite. To achieve this, they added a flame retardant additive to the fabric. After testing, they found that the new fabric was much more resistant to fire than before.

Conclusion

The Textile Oxygen Index Method (TOI) is an essential tool for assessing the fire safety performance of textile products. By understanding the impact of different factors on the TOI, manufacturers can optimize their designs and ensure compliance with regulations. Additionally, the TOI can help identify areas where products may be vulnerable to fire hazards and take steps to address these risks. As such, it is vital for the textile industry to continue investing in research and development related to this method to further enhance fire safety and protect consumer safety.

纺织品氧指数法简介

纺织品氧指数法是一种用于评估纺织品燃烧特性的方法,它通过测量纺织品在特定条件下燃烧时释放氧气的量来评估其燃烧性能,这种方法不仅适用于纺织品的质量控制,还可以为纺织品的使用提供安全保障。

氧指数法原理及操作步骤

氧指数法的基本原理是通过测量纺织品在氧气浓度为15%-25%的条件下燃烧所需的时间来评估其燃烧性能,具体操作步骤包括准备样品、设置测试环境、点燃样品进行燃烧测试等。

氧指数法测试流程示例

案例说明

纺织品氧指数测试的应用实例

某公司为了评估其生产的纺织品在特定环境下的燃烧性能,采用了氧指数法进行测试,该公司选择了不同纤维含量和织造工艺的纺织品样品,在不同氧气浓度下进行燃烧测试,测试结果表明,该公司的纺织品具有较高的燃烧性能,能够在较低的氧气浓度下保持稳定的燃烧状态。

氧指数法应用案例分析

在案例一中,我们可以看到氧指数法在纺织品质量控制中的应用,通过氧指数法的测试结果,可以有效地评估纺织品的燃烧性能,确保其在特定环境下的使用安全,这种方法还可以为纺织品的设计和生产提供参考,优化纺织品的结构和性能。

氧指数法注意事项

在进行纺织品氧指数测试时,需要注意以下几点:

- 选择合适的测试环境,确保测试条件稳定、可靠。

- 确保样品具有代表性,避免样品差异对测试结果的影响。

- 严格按照测试流程操作,确保测试结果的准确性。

纺织品氧指数法是一种有效的评估纺织品燃烧性能的方法,它不仅适用于质量控制,还可以为纺织品的使用提供安全保障,在实际应用中,我们应该根据具体情况选择合适的测试环境和方法,确保测试结果的准确性和可靠性,我们还需要不断改进和完善纺织品氧指数法的测试方法和标准,提高其应用范围和实用性。

Articles related to the knowledge points of this article:

Broadening Horizons:Exploring the Global Reach of Wus Textiles

Utilizing Textile Waste to Create a Green Future in Wuhu

Exploring the Future of Quality:The Story of Qianzhuang Textiles Company

Exploring the Beauty and Durability of Yishu Li Textile Factory

The Artful Craft of Lotus Silk Textiles

Fabric Testing in Wuxi A Journey Towards High-Quality Textiles