The Art of Textile Inspection:A Comprehensive Guide

: The Art of Textile Inspection: A Comprehensive Guide,Introduction to Textile Inspection,Textile inspection is a crucial step in the manufacturing process, ensuring that the final product meets quality standards and consumer expectations. This comprehensive guide provides an overview of the different techniques used for textile inspection, including visual inspection, mechanical testing, and chemical analysis.,Visual Inspection,Visual inspection involves the use of trained personnel to examine the fabric for defects such as holes, tears, and discoloration. This method is quick and easy to implement, but it may not detect all types of defects or identify subtle flaws.,Mechanical Testing,Mechanical testing involves subjecting the fabric to specific forces to measure its strength, flexibility, and tear resistance. This method is more effective than visual inspection in detecting defects such as holes and tears, but it requires specialized equipment and expertise.,Chemical Analysis,Chemical analysis involves analyzing the fabric's composition to identify any harmful chemicals or impurities. This method is important for products that are intended to be worn by humans or animals, as it helps ensure that they do not contain harmful substances.,Conclusion,Textile inspection is an essential part of the manufacturing process, and implementing a comprehensive guide like this one can help ensure that products meet high quality standards and consumer expectations. By using a combination of visual inspection, mechanical testing, and chemical analysis, manufacturers can identify and address any potential issues before they become a problem.

Introduction to Textile Inspection Textile inspection is a critical step in the manufacturing process, ensuring that the final product meets quality standards and consumer expectations. This process involves various methods, including visual inspection, dimensional measurement, and laboratory testing, to evaluate the fabric's appearance, fit, and functionality. In this guide, we will explore the different techniques used in textile inspection and provide an overview of the importance of this process for both manufacturers and consumers.

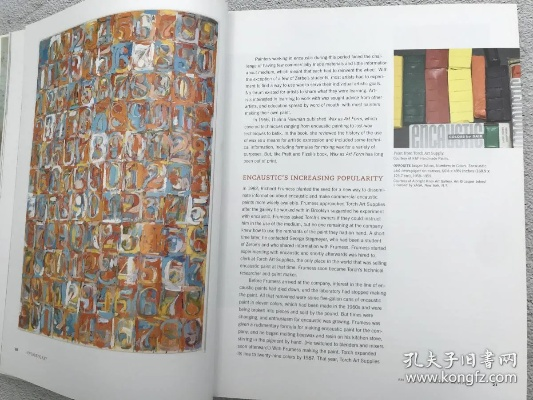

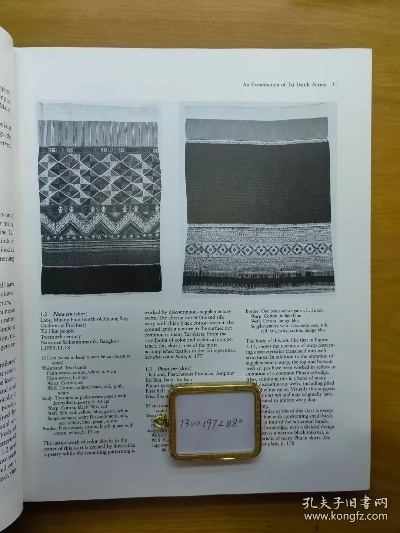

Visual Inspection Visual inspection is the first step in textile inspection. It involves examining the fabric for defects such as wrinkles, tears, holes, and color variations. This method is quick and easy to perform, but it may not detect all types of defects. To improve accuracy, manufacturers can use specialized tools like magnifying glasses or microscopes to examine more intricate details.

Dimensional Measurement Dimensional measurement is another crucial aspect of textile inspection. It involves measuring the dimensions of the fabric, including width, length, and thickness, to ensure they meet industry standards. This method is essential for garments, where proper fit is crucial for comfort and aesthetic appeal. Additionally, dimensional measurements can help identify any deviations from the original design, which may affect the overall quality of the product.

Laboratory Testing Laboratory testing is the most rigorous method used in textile inspection. It involves conducting tests on samples taken from the production line to determine their composition, texture, and durability. This method helps manufacturers identify any potential issues early on and take corrective action before the product reaches the market. Some common laboratory tests include dyeability tests, shrinkage tests, and tear strength tests.

Case Study: Textile Discrepancies Identified During Visual Inspection A textile manufacturer was experiencing discrepancies in the quality of their products after receiving feedback from customers. Upon closer inspection, the manufacturer discovered that some garments had uneven draping and loose stitching. These discrepancies were caused by a lack of attention to detail during the visual inspection process. To resolve this issue, the manufacturer implemented a new training program for their inspectors to improve their skills and attention to detail. They also introduced new tools and equipment to enhance their ability to detect subtle defects. As a result, the company was able to reduce the number of dissatisfied customers and improve their reputation among other manufacturers.

Importance of Textile Inspection Textile inspection is essential for ensuring the safety and quality of clothing, home furnishings, and other textile products. By identifying defects early on, manufacturers can take corrective action before the product reaches the market, reducing the risk of customer complaints and legal disputes. Additionally, good inspection practices can improve product durability and extend its lifespan, ultimately saving consumers money in the long run.

Conclusion In conclusion, textile inspection is a critical step in the manufacturing process that ensures the quality and safety of textile products. By utilizing visual inspection, dimensional measurement, and laboratory testing, manufacturers can detect and address any potential defects early on. This approach not only improves product quality but also enhances consumer satisfaction and loyalty. As such, investing in effective inspection practices is essential for the success of any textile manufacturer.

大家好,今天我们将探讨纺织厂如何进行检验工作,纺织行业是国民经济的重要支柱产业,而纺织厂的检验工作对于确保产品质量、提高生产效率具有重要意义,下面我们将从多个方面详细介绍纺织厂检验的方法和步骤。

检验前的准备工作

在开始检验之前,纺织厂需要做好以下准备工作:

- 确定检验标准和方法:根据产品类型、生产流程和质量要求,制定详细的检验标准和方法。

- 收集相关资料:收集产品的质量检测记录、生产流程图等相关资料。

- 安排检验人员:根据检验需求,合理安排检验人员,确保检验工作的顺利进行。

检验方法及步骤

-

外观检查: (1)检查纤维含量、颜色、光泽等外观指标是否符合标准要求。 (2)检查织物结构、质地、密度等物理性能指标是否符合设计要求。 (3)使用仪器设备对纺织品进行检测,如纤维分析仪、织物密度测试仪等。

-

化学成分检测: (1)对纺织产品进行化学成分分析,包括纤维成分、染色剂成分等。 (2)使用专业化学试剂进行样品处理,如酸碱度测试、重金属含量检测等。

-

机械性能检测: (1)对纺织产品的机械性能进行检测,包括拉伸强度、撕裂强度、耐磨性等。 (2)使用相关设备进行测试,如拉力试验机、耐磨试验机等。

-

微生物检测: (1)对纺织品进行微生物检测,包括细菌总数、真菌总数等。 (2)使用专业微生物检测设备进行样品处理和检测。

-

质量管理体系检查: (1)检查纺织厂的质量管理体系是否健全、有效。 (2)检查质量管理体系文件是否符合国家或行业标准。

案例说明

以某纺织厂为例,详细说明检验过程:

某纺织厂在检验过程中,首先确定了详细的检验标准和方法,包括纤维含量、颜色、光泽等外观指标以及机械性能等,该厂安排了专业的检验人员,对纺织品进行了全面的检测,在外观检查中,检验人员发现了一些不符合标准的问题,例如某些纤维含量不符合要求或者织物结构不够紧密等,针对这些问题,检验人员使用仪器设备进行了深入的分析和检测,并提出了相应的改进措施,在化学成分检测中,该厂使用了专业的化学试剂对样品进行了处理和分析,发现了一些不合格的化学成分,针对这些问题,该厂采取了相应的纠正措施,并对生产流程进行了优化,该厂还检查了质量管理体系是否健全、有效,并符合国家或行业标准,通过以上案例说明,我们可以看到纺织厂检验工作的复杂性和重要性。

纺织厂检验工作对于确保产品质量和提高生产效率具有重要意义,在检验过程中,纺织厂需要做好准备工作,明确检验标准和方法,合理安排检验人员,确保检验工作的顺利进行,纺织厂还需要注意采用先进的检测技术和设备,提高检验效率和准确性,纺织厂还需要加强质量管理体系建设,确保产品质量和安全生产。

Articles related to the knowledge points of this article:

The Story of Nanning Textile Factory School