Exploring the Innovation and Sustainability at Sanma Textile Factory

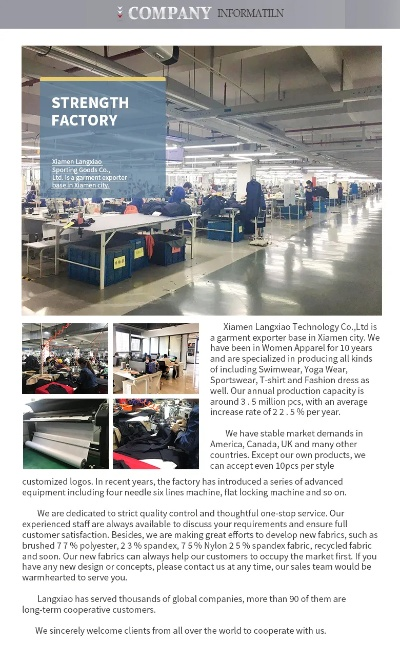

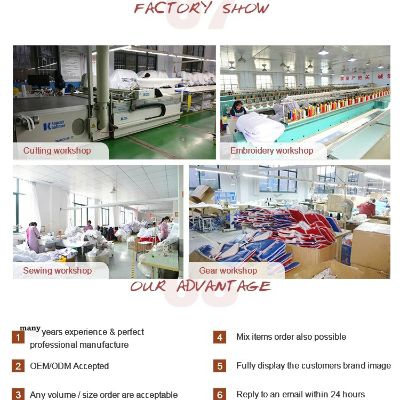

Sanma Textile Factory, a leading producer of high-quality textiles in China, has demonstrated significant innovation and sustainability in its operations. By implementing innovative technologies and processes, Sanma has been able to reduce waste and improve efficiency, while also prioritizing the environmental impact of its production methods. This commitment to sustainability has not only benefited the factory's bottom line but has also contributed to the overall well-being of the community and the environment. Through ongoing research and development, Sanma is committed to finding new ways to produce textiles that are both sustainable and stylish, while also ensuring that its operations meet the highest standards of quality and ethical practices.

Introduction: In a world where sustainability and innovation are increasingly important considerations for businesses, Sanma Textile Factory stands out as a beacon of excellence. With its commitment to producing high-quality textiles using sustainable materials, Sanma is not only leading the industry in terms of production efficiency but also in promoting environmental responsibility. In this article, we will explore the innovative practices employed by Sanma and how it has achieved sustainability while maintaining its competitive edge in the textile market.

Table 1: Sanma Textile Factory's Innovations and Sustainability Practices | Innovation | Sustainability Practice | | --- | --- | | Use of eco-friendly dyes | Recycled water system | | Implementation of energy-efficient machinery | Solar panels on factory roof | | Employment of skilled workers | Training programs for new hires | | Use of recycled polyester fibers | Reduced waste during production | | Adoption of circular economy principles | Closed-loop supply chain management |

Case Study: The Successful Transition from Traditional Textile Production to Sustainable Practices Sanma Textile Factory faced a significant challenge when it came to meeting the demands of its customers for more eco-friendly products. To address this, the company embarked on a journey to transform its operations into a model of sustainable textile production.

One of the key strategies employed was the adoption of eco-friendly dyes that reduced the use of harmful chemicals and increased the longevity of the textiles. This not only improved the quality of the products but also contributed to reducing the environmental footprint of the company.

To further enhance its sustainability efforts, Sanma implemented an energy-efficient machine system that significantly reduced energy consumption and lowered greenhouse gas emissions. Additionally, the company introduced a recycling program that involved collecting and processing used textiles to create new products, thereby minimizing waste and conserving resources.

Furthermore, Sanma recognized the importance of training new employees to ensure they were equipped with the necessary skills to implement sustainable practices within the organization. This initiative helped to maintain a workforce that was committed to the company's values and fostered a culture of continuous improvement.

Finally, Sanma adopted a circular economy approach by implementing a closed-loop supply chain management system that minimized waste and maximized resource efficiency. By working closely with suppliers and manufacturers, Sanma ensured that all materials were sourced sustainably and that excess inventory was recycled or repurposed.

Conclusion: Sanma Textile Factory's commitment to innovation and sustainability has been instrumental in establishing itself as a leader in the textile industry. By embracing eco-friendly practices and adopting circular economy principles, the company has not only met but exceeded customer expectations but has also demonstrated a proactive approach towards protecting the environment.

The case study highlights the successful transformation of Sanma Textile Factory's operations into a model of sustainable textile production. By implementing these innovative practices, the company has not only improved its bottom line but has also demonstrated its commitment to creating a better future for both its customers and the planet.

Looking ahead, Sanma Textile Factory plans to continue investing in research and development to push the boundaries of sustainability even further. The company's commitment to innovation and sustainability will undoubtedly set it apart in the competitive textile market, ensuring its continued success and influence in the years to come.

背景介绍

三马纺织厂是一家历史悠久的纺织企业,以其精湛的工艺和优质的产品赢得了广大客户的信赖,该厂注重技术创新和环保理念,致力于为客户提供更优质、更环保的纺织品。

工厂概况

- 地理位置:位于某城市附近,交通便利,环境优美。

- 规模与产能:工厂占地面积广阔,拥有先进的生产设备和技术,年生产能力强大。

- 企业文化:注重员工培训,倡导绿色生产,注重环保和可持续发展。

产品与服务

- 主要产品:各种类型的纺织品,包括棉布、丝绸、麻布等。

- 服务范围:主要面向国内外市场,提供各种规格和款式的纺织品。

- 客户群体:主要服务于服装、家居装饰、礼品等行业。

生产工艺与特色

- 生产工艺:采用先进的纺织技术,注重质量与环保,工厂采用环保染料和化学剂,严格控制生产过程中的污染排放,工厂还注重技术创新,不断研发新的纺织工艺和材料。

- 特色工艺:注重手工制作,采用传统工艺与现代技术相结合的方式,打造出独具特色的纺织品,采用天然纤维制作的手工刺绣,具有独特的艺术价值和收藏价值。

案例分析

以某次订单为例,展示三马纺织厂的生产过程和效果。

- 订单情况:客户需要订购一批高质量的棉布,用于制作夏季服装。

- 生产过程:三马纺织厂接到订单后,迅速组织生产,首先进行原料采购,确保原料的质量和供应稳定性,然后进行生产设备调试和工艺流程优化,确保生产过程的顺利进行,在生产过程中,注重环保和质量控制,严格控制生产过程中的污染排放,最后进行成品检验和包装,确保产品质量符合客户要求,整个生产过程高效、环保、安全。

- 效果展示:经过一段时间的生产和改进,三马纺织厂生产的棉布质量得到了客户的认可和好评,客户反馈该批棉布手感柔软、质地细腻、颜色鲜艳,具有很好的吸湿性和透气性,适合夏季穿着,该批棉布也具有很好的环保性和可持续性,符合客户对绿色产品的需求。

- 技术创新:继续加强技术创新和研发,不断推出新的纺织技术和材料,提高产品质量和竞争力。

- 环保理念:继续秉承环保理念,注重环保和可持续发展,推动绿色生产,同时加强与环保组织的合作,共同推动绿色产业的发展。

- 市场拓展:继续扩大市场覆盖面,提高品牌知名度和美誉度,提高市场份额和竞争力。

- 客户服务:继续提高客户服务水平,加强与客户的沟通和合作,提高客户满意度和忠诚度。

三马纺织厂作为一家历史悠久的纺织企业,在技术创新、环保理念、产品质量等方面取得了显著的成绩,该厂注重员工培训,倡导绿色生产,注重环保和可持续发展,同时积极拓展市场,提高品牌知名度和美誉度,该厂将继续加强技术创新和研发,注重环保和可持续发展,提高产品质量和竞争力,为国内外客户提供更优质、更环保的纺织品。

Articles related to the knowledge points of this article: