The Cost of Green Textiles:An Overview and Analysis

This paper explores the costs associated with producing green textiles, a term often used to describe eco-friendly or sustainable fabrics. The primary costs include raw material sourcing, energy consumption during production, and waste disposal. Raw materials for green textiles are typically more expensive than traditional ones due to their environmentally friendly nature and higher quality standards. In addition, the production process requires significant amounts of energy, which can be costly in terms of electricity and fuel. Finally, proper disposal of the textiles' end-of-life products is crucial for reducing environmental impact. This paper provides an overview and analysis of these costs, highlighting the importance of sustainable practices in the textile industry.

Introduction: In today's world, sustainability has become an essential aspect of our lives. As consumers, we are increasingly conscious of the environmental impact of our daily choices. This includes the textile industry, where the production of green textiles is gaining momentum as more companies strive to reduce their carbon footprint and promote eco-friendly practices. In this article, we will explore the costs associated with producing green textiles, including raw materials, manufacturing processes, and disposal. We will also present a case study that highlights the benefits of investing in green textiles for both the environment and the economy.

Raw Materials Costs: The first step in creating green textiles is sourcing sustainable raw materials. These materials must be certified by reputable organizations such as the Global Organic Textile Standard (GOTS) or Fair Trade Certified™ to ensure they meet high standards of environmental and social responsibility. The cost of these materials can vary significantly depending on the type of fiber used and the certification process involved. For example, organic cotton, which is grown without the use of harmful pesticides and fertilizers, may be more expensive than conventional cotton. Similarly, bamboo fabric, which is biodegradable and sustainably sourced, may require additional processing steps to achieve its properties.

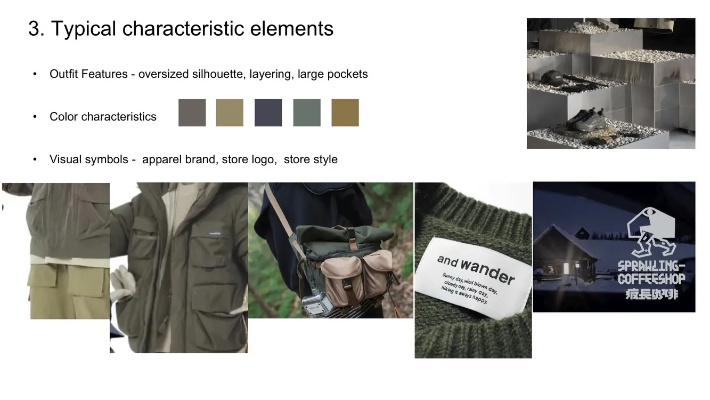

Manufacturing Processes: Once the raw materials have been collected, they must be processed into usable textile products. This process can be energy-intensive and produce significant amounts of waste. To reduce these emissions and minimize waste, manufacturers are implementing various technologies such as dye-free printing, water-based dyes, and low-temperature dyeing processes. These techniques not only improve the environmental performance of the product but also increase efficiency and reduce labor costs. However, these advanced manufacturing processes can be costly, particularly when compared to traditional methods.

Disposal and Waste Management: After the textile product is finished, it must be disposed of in a responsible manner. Many green textiles are designed to be durable and reusable, reducing the need for new products. However, even these products eventually reach the end of their life cycle and must be properly managed. Manufacturers are working towards reducing their environmental footprint by using recycled materials and implementing recycling programs. Additionally, some companies are exploring innovative solutions such as upcycling existing textiles into new products or using them in other industries.

Case Study: One company that has successfully implemented green textile practices is Patagonia. The outdoor apparel retailer was one of the first to adopt sustainable practices in its supply chain, from sourcing organic cotton to using recycled polyester in its clothing. Patagonia's commitment to sustainability has not only benefited the environment but also increased consumer trust and loyalty. By offering products that are not only stylish but also ethically produced, Patagonia has established itself as a leader in the green fashion industry.

Conclusion: The cost of green textiles is often perceived as higher upfront, but the long-term benefits far outweigh the initial investment. By choosing green textiles, we can reduce our ecological footprint, save money in the long run, and create a more sustainable future for ourselves and generations to come. As the demand for sustainable products continues to grow, it is crucial that we prioritize the environmental impact of our choices. By embracing green textiles, we can all play a part in making a positive impact on our planet.

随着环保意识的日益增强,绿色针纺织品已成为市场上的新趋势,本文将围绕绿色针纺织品费用展开讨论,通过案例分析,探讨其成本构成及影响因素。

绿色针纺织品费用构成

- 材料成本:主要涉及天然纤维的选择和品质控制,优质天然纤维如环保棉、再生纤维等具有较低的生产成本,同时环保标准要求也相应降低。

- 工艺成本:涉及纺织工艺的环保改造和优化,如采用环保染料、节能减排技术等,这些工艺改进可以降低能耗和排放,减少生产成本。

- 研发成本:包括绿色针纺织品的设计研发、测试验证等环节,需要投入大量的人力、物力和财力。

- 运输与存储成本:涉及绿色针纺织品从生产到销售过程中的运输和存储费用,随着物流行业的快速发展,绿色运输和存储方式可以降低成本。

案例分析

以某知名品牌为例,介绍绿色针纺织品费用的具体构成及实际案例。

- 材料成本:该品牌主要采用环保棉作为主要材料,同时注重天然纤维的品质控制,通过与优质纤维供应商合作,确保原材料的品质和供应稳定性。

- 工艺成本:该品牌在纺织工艺方面进行了大量的环保改造和优化,采用了先进的节能减排技术,有效降低了能耗和排放,该品牌还注重绿色生产线的建设和管理,确保生产过程的环保性和可持续性。

- 研发成本:该品牌投入大量资金进行绿色针纺织品的设计研发,不断推出符合市场需求的新产品,该品牌还与科研机构合作,进行新技术和新材料的研发和应用。

- 实际案例:该品牌在某次促销活动中,通过优化运输和存储方式,降低了运输和存储成本,通过提高产品质量和客户满意度,提高了品牌的市场竞争力。

影响因素分析

- 材料品质:优质的材料是绿色针纺织品的基础,直接影响着费用成本,高品质的材料可以降低生产成本,提高产品质量。

- 环保政策:环保政策的变化也会对绿色针纺织品费用产生影响,随着环保要求的不断提高,绿色针纺织品的生产成本也会相应提高。

- 市场竞争:市场竞争激烈程度也会对绿色针纺织品费用产生影响,在市场竞争中,企业需要不断提高自身竞争力,以降低费用成本。

- 物流成本:随着物流行业的快速发展,绿色运输和存储方式可以降低物流成本,企业需要选择合适的物流方式,确保产品的及时送达和存储。

绿色针纺织品费用是一个综合性的问题,涉及到材料成本、工艺成本、研发成本、运输与存储成本等多个方面,企业需要综合考虑各种因素,制定合理的成本控制策略,以降低绿色针纺织品费用,提高市场竞争力,政府也需要出台相关政策,鼓励和支持绿色针纺织品的发展,推动行业可持续发展。

Articles related to the knowledge points of this article:

Exploring the Global Market for Textiles at the National Textile Exhibition