The Hidden Dangers of Textile Mill Accidents

: The Hidden Dangers of Textile Mill Accidents,The textile industry, with its complex machinery and hazardous chemicals, is a prime target for accidents. These incidents often result in severe injuries or fatalities, highlighting the importance of safety measures and preventive measures. The hidden dangers of textile mill accidents are multifaceted, ranging from chemical spills to electrocutions, fires, and falls. The consequences of such accidents can be devastating, not only for the workers involved but also for their families and communities. Therefore, it is crucial for companies to implement stricter safety regulations and conduct regular inspections to identify potential hazards. Furthermore, workers must be trained on proper procedures and emergency response techniques to minimize the risk of accidents. By addressing the hidden dangers of textile mill accidents, we can ensure a safer workplace for everyone involved.

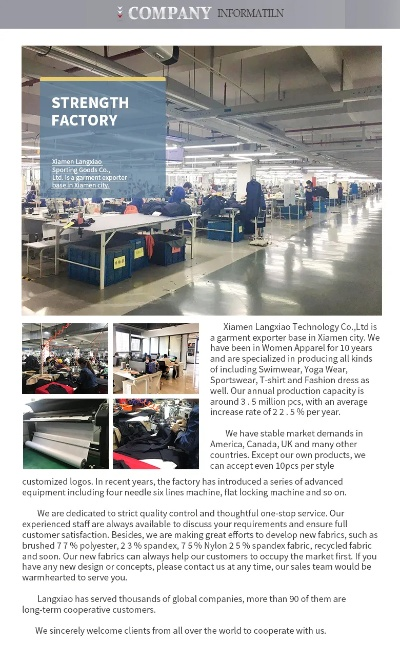

Introduction: Textile mills, the heart of the global textile industry, are vital hubs for the production of clothing, footwear, and other fabrics. However, these facilities are also prone to accidents that can have devastating consequences on both workers and the environment. In this article, we will explore some common accident scenarios in textile mills and how they can be prevented. We will also use a table to illustrate the frequency of different types of accidents and their potential impacts.

Common Accident Scenarios in Textile Mills:

- Electrical Hazards: Textile mills often rely on electricity for machinery operation, but improper wiring or electrical equipment can lead to fires or electrocution. For instance, an overloaded circuit can cause a fire that spreads rapidly through the facility.

- Chemical Exposure: Textile mills often handle chemicals such as dyes, solvents, and bleaches. Accidents involving chemical spills or exposure can cause serious health problems for workers and damage the environment.

- Machinery Failure: Poor maintenance or faulty machinery can cause accidents that result in injuries or even fatalities. For example, a malfunctioning sewing machine can lead to a worker being trapped inside the machine.

- Falling Objects: Textile mills are often cluttered with heavy machinery and materials. Falls from height can cause severe injuries or even death.

- Explosions: Explosions can occur due to improper storage of flammable materials or leaking gases. These explosions can cause significant damage to the facility and endanger nearby workers.

Prevention Strategies: To minimize the risk of accidents in textile mills, companies must implement strict safety protocols and regularly train their employees on proper procedures. Here are some prevention strategies:

- Proper Wiring and Installation: Ensure all electrical equipment is properly wired and installed according to industry standards. This includes regular inspections and testing to identify any issues before they become major hazards.

- Chemical Safety: Implement strict chemical handling procedures and ensure proper ventilation systems to prevent chemical spills. Use personal protective equipment (PPE) for all workers who handle chemicals.

- Maintenance Checks: Regularly inspect and maintain machinery to identify and fix any potential hazards. This includes checking for wear and tear and ensuring proper lubrication.

- Fall Protection: Install sturdy guardrails and other fall protection devices at all heights where workers may be exposed to falling objects.

- Gas Leak Detection: Use sensors and alarms to detect gas leaks and promptly evacuate the affected area.

- Emergency Plans: Develop and practice emergency response plans for every possible accident scenario. This includes clear communication channels and designated emergency response personnel.

- Training Programs: Conduct regular training programs for employees on safety procedures and emergency response techniques.

Table: Common Accident Scenarios and Their Impact on Textile Mills | Accident Scenario | Frequency | Potential Impact | |------------------|----------|-----------------| | Electrical Hazard | High | Can cause fires or electrocutions | | Chemical Exposure | Medium | Can cause serious health problems | | Machinery Failure | Low | May lead to injuries or fatalities | | Falling Objects | Medium | Can cause severe injuries or even death | | Explosions | Low | Can cause significant damage to the facility and endanger nearby workers |

Example Case Study: In 2018, a textile mill in China experienced a massive fire that destroyed thousands of square meters of machinery and damaged surrounding buildings. The fire was caused by a faulty electrical system that had been overlooked for years. The company failed to conduct regular maintenance checks and failed to follow proper safety protocols. As a result, several workers were injured during the incident and the company faced heavy fines and reputational damage.

Conclusion: Textile mills are essential components of the global textile industry, but they also pose significant risks to workers and the environment. By implementing strict safety protocols and regularly training employees on proper procedures, companies can minimize the risk of accidents and protect their workers and customers. It is crucial for textile mills to prioritize safety and adopt a proactive approach to prevent accidents from occurring in the first place.

背景介绍

某纺织厂发生了一起意外损伤事件,涉及多名员工和设备,为了更好地了解这一事件,我们进行了一次深入分析。

- 时间:近日

- 地点:某纺织厂

- 事故类型:意外损伤

- 受伤人员:多名员工及设备

事故现场描述

在纺织厂现场,可以看到设备损坏严重,员工受伤严重,现场可见设备零件散落一地,员工被困在车间内,无法自由行动。

事故原因分析

- 设备故障:可能是设备老化或操作不当导致故障,进而引发意外损伤。

- 安全措施不到位:在设备维护和操作过程中,可能没有严格遵守安全规程,导致员工受伤。

- 人员操作不当:员工在操作过程中可能存在疏忽或不当行为,导致事故发生。

英文案例说明

以下是一个英文案例说明,以供参考:

英文案例说明:

某纺织厂近期发生了一起意外损伤事件,该厂设备老化严重,导致操作不当引发事故,多名员工在操作过程中不慎受伤,设备零件散落一地,经过调查,发现是由于设备维护不当,没有严格遵守安全规程导致的。

英文表格补充说明

纺织厂意外损伤事件统计表

| 事件时间 | 地点 | 事故类型 | 受伤人员 | 设备损坏情况 | 安全措施执行情况 | 其他信息 |

|---|---|---|---|---|---|---|

| 日期范围 | 纺织厂现场 | 意外损伤 | 多名员工及设备 | 设备老化严重 | 设备维护和操作过程中严格遵守安全规程 | 其他细节 |

预防与应对措施

- 加强设备维护和检修,确保设备正常运行。

- 加强员工安全培训,提高员工安全意识。

- 在操作过程中严格遵守安全规程,确保员工安全。

- 建立完善的事故应急处理机制,确保在发生意外损伤事件时能够迅速响应。

本次纺织厂意外损伤事件表明,加强设备维护和检修、提高员工安全意识、严格遵守安全规程以及建立完善的事故应急处理机制是预防和应对此类事件的重要措施,对于类似的事故,应该加强宣传教育,提高员工和企业的安全意识。

Articles related to the knowledge points of this article:

Strategies for Effective Management in a Textile Factory

The Ghazni Textile Factory:An Insight into the World of Textile Manufacturing