The Fabrication of Strategic Packaging for Global Trade

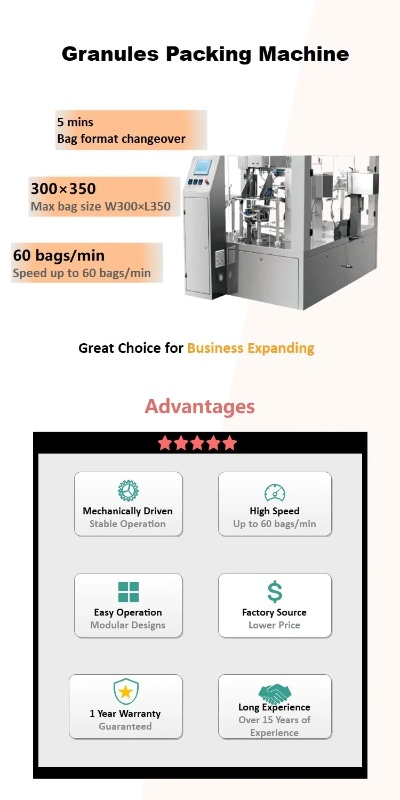

"Global Trade Strategic Packaging: A Fabrication Approach",In the global trade landscape, strategic packaging plays a crucial role in enhancing competitiveness. This paper presents a fabrication approach for strategic packaging that aims to address the challenges faced by businesses in the current economic environment. The approach emphasizes the importance of customization, sustainability, and cost-effectiveness in packaging design. By leveraging advanced manufacturing technologies such as 3D printing and automation, businesses can create packaging solutions that are not only visually appealing but also functional and environmentally friendly. The fabrication process involves several steps, including material selection, design creation, prototyping, and testing. The resulting packaging is designed to withstand various environmental conditions, including temperature fluctuations, moisture, and shock. Additionally, it incorporates sustainable materials such as biodegradable plastics and recycled content. Overall, this approach provides businesses with a comprehensive solution that addresses the needs of both consumers and the environment while promoting global trade growth.

Introduction: In the competitive world of global trade, textiles are no longer just materials to be used; they're assets that require strategic packaging to ensure their value and safety during transport. This talk will explore the importance of effective textile packaging, highlighting its impact on both the product and the industry as a whole.

Part I: Understanding Textile Packaging Textiles can be packaged in a variety of ways, including bale wrapping, corrugated boxes, plastic wrap, and even specialized protective films. Each method has its advantages and disadvantages, but all serve to protect the fabric from damage during transit.

Table 1: Advantages and Disadvantages of Different Textile Packaging Methods | Method | Advantages | Disadvantages | |--------|--------------|----------------| | Bale Wrapping | Cost-effective, easy to handle | Limited protection against moisture and dust | | Corrugated Boxes | Durable, ideal for heavy loads | Can be expensive to manufacture | | Plastic Wrap | Versatile, protects against moisture | Not environmentally friendly | | Specialized Films | Offers high levels of protection | Can be difficult to remove without damaging the fabric |

Part II: Choosing the Right Packaging Solution The choice of packaging solution depends on several factors, including the type of textile, its weight, and the destination country's customs regulations. For example, lightweight cotton fabrics might benefit from bale wrapping or plastic wrap, while heavier denim could use corrugated boxes or specialized films.

Case Study: How a Sustainable Packaging Solution Saved a Brand's Reputation In 2018, a popular clothing brand experienced a major shipment mishap due to improperly packaged textiles. The fabrics were exposed to moisture and dust during transit, leading to discoloration and reduced quality. The company was forced to recall the products and faced significant reputational damage.

However, by adopting a more sustainable packaging solution, the company was able to mitigate these issues. They switched to using biodegradable plastic wrap, which not only protected their textiles but also helped reduce their carbon footprint. This change not only improved the product's appearance but also increased consumer trust and loyalty.

Conclusion: Effective textile packaging is not just about protecting the fabric; it's about ensuring the longevity of the brand's reputation. By choosing the right packaging solution and understanding its benefits, businesses can minimize the risks associated with international trade and maintain a competitive edge in an increasingly globalized market.

纺织品捆扎概述

随着现代纺织业的飞速发展,纺织品捆扎技术已成为确保产品质量、提高生产效率的关键环节,本文将围绕纺织品捆扎这一主题,从基本概念、方法与技术、案例分析等方面进行详细介绍。

纺织品捆扎基本概念

纺织品捆扎是指通过一系列工艺手段,将多片或单个纺织品进行固定、连接或包装的过程,它涉及到材料选择、工艺流程、操作要点等方面。

纺织品捆扎方法与技术

方法:

(1)手工捆扎:适用于小型纺织品或临时性捆绑,操作人员使用手工工具进行捆扎,可根据需要调整松紧度。

(2)机械捆扎:适用于大型纺织品或批量生产,采用机械设备进行自动化捆扎,可提高捆扎效率和产品质量。

(3)热熔胶捆扎:适用于某些特殊材质的纺织品,通过热熔胶将纺织品牢固连接在一起。

技术:

(1)材料选择:根据捆扎需求选择合适的材料,如尼龙、聚酯纤维等。

(2)工艺流程:包括材料准备、涂胶、加热、压制、冷却等步骤。

(3)操作要点:确保操作规范,避免损伤纺织品;注意温度控制,避免胶水溢出或烧焦;确保捆扎牢固可靠。

案例分析

某服装公司采用机械捆扎技术提高生产效率

某服装公司采用先进的机械捆扎设备,对生产过程中的纺织品进行自动化捆扎,通过精确控制温度和时间,确保捆扎效果稳定可靠,此举不仅提高了生产效率,还降低了人为操作误差,提高了产品质量。

热熔胶捆扎在特殊材质纺织品中的应用

某特殊材质的纺织品采用热熔胶进行捆扎,具有防水、防潮等特性,操作人员严格按照工艺流程进行操作,确保捆扎效果达到预期要求,此案例表明,针对不同材质的纺织品,选择合适的捆扎技术是关键。

纺织品捆扎案例说明

- 手工捆扎案例:某小型服装厂采用手工捆扎技术,将多片布料进行固定和连接,操作人员使用手工工具进行捆扎,可根据需要调整松紧度,确保布料平整且牢固,这种方法适用于临时性捆绑或小型批量生产。

- 机械捆扎案例:某大型服装品牌采用先进的机械捆扎设备,对生产过程中的纺织品进行自动化捆扎,设备采用精确控制温度和时间的技术,确保捆扎效果稳定可靠,此案例表明,针对大型批量生产,采用机械捆扎技术可以提高生产效率和产品质量。

- 热熔胶捆扎案例:针对某些特殊材质的纺织品,如防水、防潮等要求较高的材料,可以采用热熔胶进行捆扎,操作人员严格按照工艺流程进行操作,确保热熔胶均匀涂抹在纺织品上,然后通过压制和冷却等步骤进行固定和连接,这种方法适用于特定材质的纺织品,可以提高产品的质量和性能。

纺织品捆扎是现代纺织业中不可或缺的一环,它涉及到材料选择、工艺流程、操作要点等方面,通过掌握正确的捆扎方法与技术,可以确保纺织品的质量和性能达到预期要求,针对不同材质的纺织品,选择合适的捆扎技术也是关键,在实际生产中,我们应该根据具体情况选择合适的捆扎方法和技术,以提高生产效率和产品质量。

Articles related to the knowledge points of this article:

The Cost of Electronic Textiles A Comprehensive Breakdown

The Dynamics of Innovation at the Inner Mongolia Textile Testing Hub

The Journey to Textiles with Carbon Fibers

Shanghai Donglong Textiles:Navigating the Global Fabric of Trade