Standards for Tear Proneness in Textiles

Tear-proneness is a critical quality parameter in the textile industry, as it directly affects the durability and longevity of apparel. This paper discusses the standards for tear-proneness in textiles, focusing on factors such as fabric structure, yarn properties, and finishing techniques. It also explores the impact of environmental conditions on tear-proneness, including temperature, humidity, and air circulation. The paper concludes by highlighting the importance of maintaining consistent tear-proneness levels to ensure the quality and safety of apparel products.

Introduction: Textiles, whether they be clothing, upholstery, or industrial fabrics, are an integral part of our daily lives. However, the durability and resistance to wear and tear are often measured by the quality of the material itself. One key factor that determines how well a textile resists tearing is its tear propensity, which refers to the tendency of the fibers to break apart under stress. In this article, we will discuss some of the common methods used to measure and classify the tear propensity of textiles, including a table outlining the various standards. We will also present an illustrative case study to demonstrate how these standards can be applied in practice.

Tear Propensity Measurement Methods: There are several methods used to assess the tear propensity of textiles, each with its own advantages and limitations. Here's a table summarizing some of the most common methods:

| Method | Advantages | Disadvantages |

|---|---|---|

| Tensile Testing | Highly accurate, but requires specialized equipment and trained personnel | Can be time-consuming and expensive |

| Bursting Testing | Simple and quick, but may not accurately reflect real-world tearing conditions | May not capture all types of tears |

| Scaling Testing | Predictive of long-term durability, but may not capture short-term tearing | Not suitable for certain types of textiles |

| Dimpling Testing | Can simulate real-world tearing conditions, but may not fully represent the strength of the fabric | Requires specialized equipment and expertise |

Classification of Tear Propensity: The tear propensity of textiles can be classified based on their susceptibility to tearing under normal use conditions. Here are some common classifications:

- Low Tear Propensity (LTPP)

- Medium Tear Propensity (MTPP)

- High Tear Propensity (HTP)

- Very High Tear Propensity (VHTP)

Low Tear Propensity (LTPP): This category includes textiles that are resistant to most everyday wear and tear. Examples include high-quality denim jeans, which are designed to withstand heavy usage and washing.

Medium Tear Propensity (MTPP): Textiles in this category have moderate levels of tear resistance but still maintain sufficient durability for most everyday activities. For example, cotton t-shirts are typically considered MTPP.

High Tear Propensity (HTP): Textiles in this category are susceptible to tearing under normal circumstances. However, they can still withstand more intense wear and tear than other categories. Examples include athletic apparel, which may have higher levels of tear resistance than casual wear.

Very High Tear Propensity (VHTP): Textiles in this category are extremely prone to tearing under normal conditions. They require special care and maintenance to maintain their appearance and functionality. Examples include fine silk fabrics, which are highly susceptible to creasing and wrinkling.

Case Study: To illustrate how these standards can be applied in practice, let's consider a textile company that produces high-quality denim jeans. The company has developed a standardized process for measuring the tear propensity of each batch of jeans, using both tensile testing and scaling tests. The results are then categorized according to the classification system outlined above. This information is used by the company's marketing team to communicate the level of durability and resistance to wear and tear to consumers. By highlighting the jeans' high MTPP rating, the company can attract customers who appreciate the quality and longevity of their clothing.

Conclusion: Understanding the tear propensity of textiles is crucial for manufacturers, retailers, and consumers alike. By employing appropriate measurement methods and classifying textiles according to their tear resistance, we can ensure that products meet the expectations of those who rely on them for daily use. With the right knowledge and tools, we can create textiles that not only look good but also last for years to come.

在日常生活中,纺织品是我们日常生活中不可或缺的一部分,为了确保纺织品的质量和安全性,我们制定了相应的撕破标准,本篇文章将围绕纺织品的撕破标准展开讨论,并通过案例分析进一步说明。

纺织品的撕破标准概述

定义与分类

纺织品的撕破标准是指对纺织品在特定条件下进行撕破测试,以确保其在使用过程中不会出现撕裂、破损等现象,根据不同的纺织品类型和应用场景,撕破标准也有所不同。

测试方法与标准

常见的纺织品的撕破测试方法包括静态撕裂强度测试和动态撕裂强度测试,静态撕裂强度测试通常用于检测纺织品在静态环境下的抗撕裂性能,而动态撕裂强度测试则用于模拟实际使用场景下的撕裂性能。

案例分析

常见纺织品撕破标准的适用性

某品牌的一款女士连衣裙,其撕破标准主要包括静态撕裂强度测试,根据该品牌的产品说明,该连衣裙采用了高品质的纤维材料,经过严格的生产工艺处理,确保其在正常使用条件下具有良好的抗撕裂性能。

特殊纺织品撕破标准的特殊要求

对于某些特殊用途的纺织品,如防水、防污等特殊功能的纺织品,其撕破标准可能更加严格,某些防水地毯或防污窗帘等,其撕破标准不仅要求静态撕裂强度测试合格,还可能需要进行动态撕裂强度测试等其他相关测试,以确保其在特定使用场景下的性能。

纺织品的撕破标准补充说明

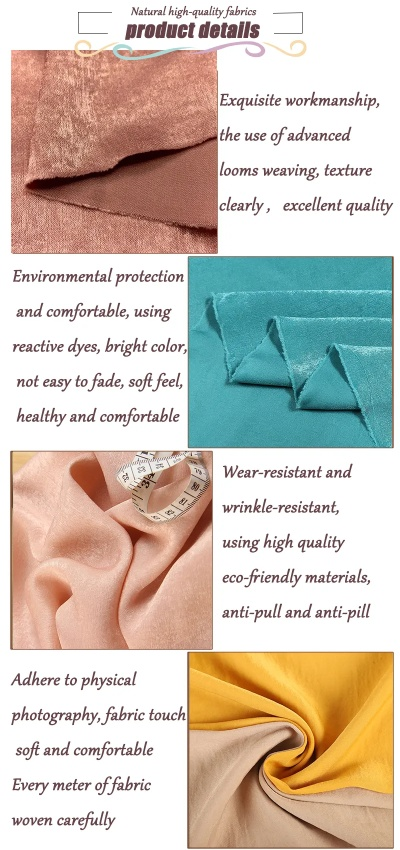

纤维类型与性能的关系

不同纤维类型对纺织品的抗撕裂性能有着重要影响,某些高强度纤维具有较高的撕裂强度,适用于需要高抗撕裂性能的纺织品;而某些柔软纤维则更适合柔软舒适的纺织品,在选择纺织品时,需要根据其用途和要求选择合适的纤维类型。

生产过程中的质量控制

生产过程中的质量控制是确保纺织品撕破标准的重要环节,在生产过程中,需要严格控制纤维的质量、纺丝工艺、织造工艺等关键环节,以确保纺织品在生产过程中的质量稳定性和一致性,还需要进行严格的检验和测试,以确保纺织品在出厂前符合相应的撕破标准。

总结与建议

纺织品的撕破标准是确保纺织品在使用过程中不会出现撕裂、破损等现象的重要标准,在实际应用中,我们需要根据不同的纺织品类型和应用场景,选择合适的撕破标准,我们还需要加强生产过程中的质量控制,确保纺织品在生产过程中的质量稳定性和一致性,我们还可以通过加强宣传和教育,提高消费者对纺织品撕破标准的认识和重视程度。

Articles related to the knowledge points of this article:

Mastering Photoshop for Editing Textiles A Comprehensive Guide

Exploring the Rich Tapestry of Cotton Textiles in Shaoxing

Technological Advancements:The Backbone of Digital Transformation

The Dynamic World of Foreign Trade Textiles and their Fabric Characteristics