The Key Ingredients of Glass Textiles:An Illustrated Guide

"The Key Ingredients of Glass Textiles: An Illustrated Guide" is a comprehensive guide that delves into the essential components of glass textiles, providing an illustrated overview of the materials, techniques, and applications involved in creating these fascinating products. From the selection of raw materials to the final assembly process, this guide covers every aspect of glass textile production, offering readers a thorough understanding of what makes these textiles unique and valuable.,With its clear and engaging language, this guide aims to inspire both beginners and experts in the field of glass textiles, providing them with the knowledge they need to create beautiful and functional pieces that can be used in a variety of applications. Whether you're interested in exploring new design possibilities or simply expanding your knowledge of this fascinating industry, this guide is a must-read for anyone who wants to get started or deepen their understanding of glass textiles.

Introduction: Glass textiles, also known as glass fibers or glass fabrics, are a fascinating blend of science and art. These materials, made from the pulverized glass, have found applications in various industries such as construction, automotive, electronics, and more. In this article, we will delve into the components that make up these remarkable textiles and explore their properties through an illustrated guide.

Components:

-

Glass Fibers: The primary ingredient in glass textiles is the glass fiber, which is a long, thin filament made from molten silica. It is the backbone of the material, providing strength and rigidity.

-

Silane Coupling Agent: This chemical compound is used to bind the glass fibers together, creating a strong bond that enhances the overall performance of the textile.

-

Polymer Resin: This is a polymeric substance that fills in the gaps between the glass fibers, creating a continuous network structure that allows for better flexibility and resistance to wear and tear.

-

Heat-Resistant Adhesive: This adhesive helps to hold the glass fibers together and prevent them from coming loose during high temperatures.

-

Colorants: These are added to the glass fibers to give them a desired color and appearance. They can be natural pigments or synthetic dyes.

-

Antistatic Agent: To prevent static buildup and improve the handling of the textile, antistatic agents are added.

-

Flame Retardant Additives: These chemicals help to reduce the risk of fire by creating a barrier on the surface of the textile.

-

UV Stabilizers: These protect the glass fibers from ultraviolet rays, which can cause degradation over time.

-

Antimicrobial Agents: Some glass textiles are treated with antimicrobial agents to prevent the growth of harmful bacteria or fungi.

-

Fillers: These are small particles added to the glass fibers to increase its density and improve its mechanical properties.

Properties:

-

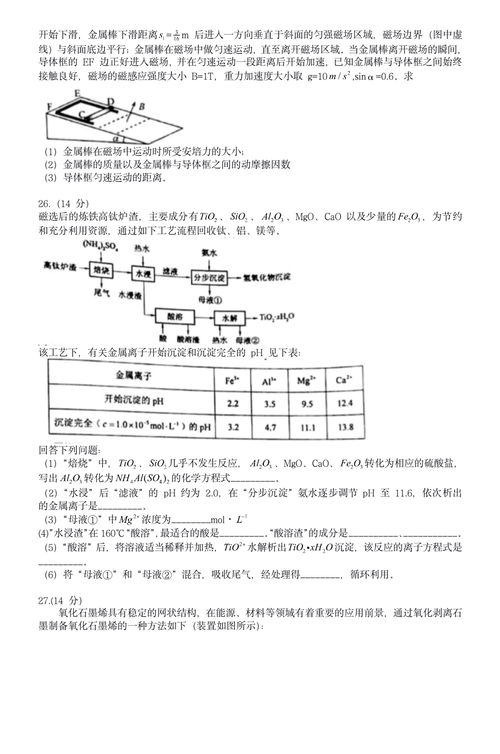

Strength and Durability: Glass textiles are incredibly strong and durable, making them ideal for outdoor applications where they can withstand harsh weather conditions.

-

Lightweight: Despite their strength, glass textiles are lightweight, making them ideal for use in aircraft structures or in construction projects where weight is a consideration.

-

Flexibility: The interconnected nature of the fibers allows for excellent flexibility, making it possible to create intricate designs and patterns.

-

Ease of Cleaning: Glass textiles are easy to clean and maintain, making them popular in areas where hygiene is critical.

-

Biodegradability: When disposed of properly, glass textiles can biodegrade, reducing their environmental impact.

Case Study: One example of how glass textiles are used is in the construction industry. For instance, glass fiberglass is commonly used in the manufacture of roof tiles, siding, and other building materials. It provides excellent insulation properties and is highly resistant to corrosion, making it a popular choice for coastal regions where exposure to saltwater is common.

Conclusion: In conclusion, glass textiles are a marvel of modern engineering, combining the strength and durability of glass with the flexibility and beauty of textiles. By understanding the key ingredients and properties of these materials, we can harness their full potential and create innovative solutions for a variety of applications.

各位朋友们,今天我们来聊聊玻璃纺织品的主要成分及其背后的故事,让我们一起来探索这个神奇的纺织世界吧!

玻璃纺织品的成分构成

玻璃纺织品主要由以下几种主要成分组成:

-

玻璃纤维:这是玻璃纺织品的主要组成部分,玻璃纤维是一种由高纯度玻璃制成的纤维材料,具有高强度、高韧性、耐腐蚀等特性,它广泛应用于各种工业领域,如建筑、汽车、航空航天等。

-

聚合物:聚合物是玻璃纤维和其他化学物质混合而成的材料,用于增强玻璃纤维的强度和耐久性,常见的聚合物有聚丙烯、聚酯等。

-

染色剂:为了使玻璃纺织品呈现出特定的颜色或图案,还会添加染色剂,染色剂可以是天然染料或合成染料,用于赋予纺织品颜色和纹理。

案例分析

让我们通过一个具体的案例来进一步了解玻璃纺织品的成分及其应用。

环保玻璃纺织品

近年来,环保玻璃纺织品越来越受到人们的关注,这种纺织品通常使用可再生资源制造,如回收的玻璃碎片和聚合物,它们不仅具有美观的外观,而且具有环保特性,减少了生产过程中的环境污染,某公司研发的一款环保玻璃纺织品,采用了回收的玻璃碎片作为主要原料,经过特殊工艺处理后制成衣物或窗帘等家居用品,这种纺织品不仅美观实用,而且符合环保理念,深受消费者喜爱。

玻璃纺织品的介绍

朋友们,玻璃纺织品是一种由特殊材料制成的纺织品,具有独特的外观和性能,它们通常由玻璃纤维、聚合物和其他化学物质混合而成,可以制作出各种颜色、图案和质地,这种纺织品不仅美观大方,而且具有优良的耐用性和抗腐蚀性,可以长时间保持其原有的质量和外观。

主要成分及其作用

(1)玻璃纤维:玻璃纤维是一种高强度、高韧性的纤维材料,可以增强纺织品的强度和耐久性,它还具有很好的绝缘性和耐腐蚀性,可以用于制作各种电器产品、航空航天等领域。

(2)聚合物:聚合物是玻璃纤维和其他化学物质混合而成的材料,可以增强纺织品的柔软性和弹性,它还可以赋予纺织品特定的颜色和纹理,使其更加美观。

实际应用案例

在现实生活中,玻璃纺织品的应用非常广泛,在建筑领域中,玻璃纺织品可以用于制作窗户、门帘、墙布等家居用品;在汽车行业中,玻璃纺织品可以用于制作汽车内饰、车窗等;在航空航天领域中,玻璃纺织品可以用于制作飞机座椅、窗户等部件,随着环保理念的普及,环保玻璃纺织品也越来越受到人们的关注和喜爱。

玻璃纺织品是一种由特殊材料制成的纺织品,具有独特的外观和性能,它们的主要成分包括玻璃纤维、聚合物和其他化学物质混合而成,可以制作出各种颜色、图案和质地,随着科技的不断发展和人们对于环保、美观等方面的需求不断提高,玻璃纺织品的未来将会更加广阔和多样化。

Articles related to the knowledge points of this article:

Testing Fabric Content for Fibers in Textile Industry

Industrial Printing Textile Testing Standards

The Transformative Power of Bamboo in Textiles