The Transformative Power of Automotive Interior Textiles Recycling

The Transformative Power of Automotive Interior Textiles Recycling,In the realm of sustainable development, the recycling of automotive interior textiles has emerged as a powerful force for positive change. The textiles found in car interiors, such as seats, curtains, and upholstery, are not only an integral part of the driving experience but also a significant contributor to the environmental footprint of vehicles. By properly recycling these materials, we can not only reduce our carbon footprint but also create new opportunities for economic growth and innovation.,The process of recycling automotive interior textiles involves several steps, including sorting, cleaning, and then transforming the textiles into new products. This process is not only cost-effective but also helps to repurpose these materials in innovative ways that can benefit both the environment and society.,As consumers, we have the power to make a difference by choosing to recycle these textiles or supporting companies that specialize in their recycling. By doing so, we can contribute to a more sustainable future while also enjoying the benefits of modern technology and design.

Introduction: In the ever-evolving world of automotive manufacturing, sustainability has become an increasingly important consideration. One area where this principle can be particularly applied is in the recycling and repurposing of materials used within the interior textiles of cars. By leveraging these textiles, we can not only reduce waste but also create a more eco-friendly alternative to traditional materials. This talk will explore how recycling automotive interior textiles can benefit both the environment and the economy.

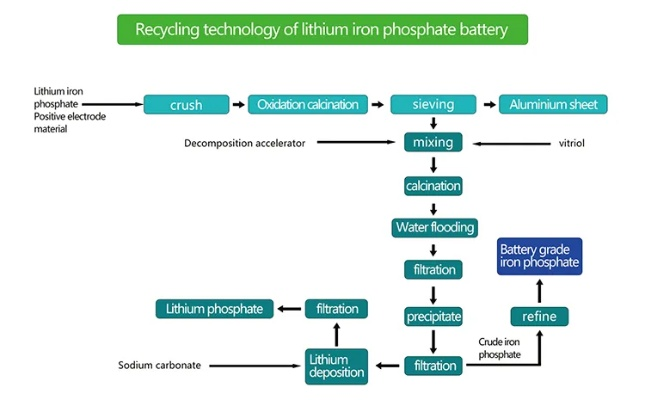

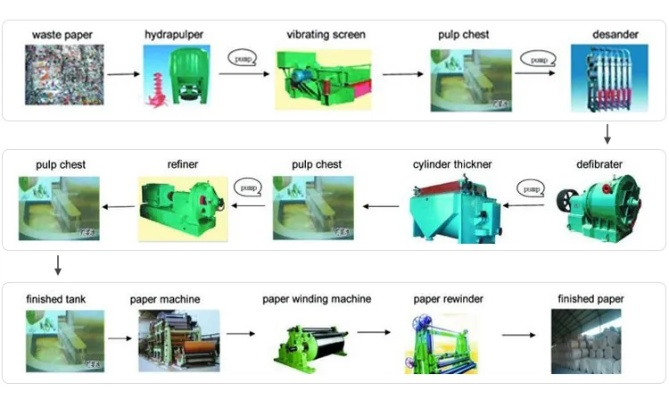

Textile Recycling Process: Automotive interior textiles are made from a variety of materials, including cotton, polyester, and nylon. These textiles are often discarded after a single use due to their durability and ease of cleaning. However, when properly recycled, they can be transformed into new products that serve as sustainable alternatives to traditional materials.

The process begins with sorting. Various types of textiles are sorted based on their color, texture, and intended use. For example, cotton is separated from polyester or nylon. Once sorted, the textiles undergo a series of steps to remove any contaminants and prepare them for further processing.

Next, the textiles are washed and dried to remove any residual dirt or oils. This step is crucial as it helps to prevent contamination during the subsequent recycling process.

After washing, the textiles are then shredded into small pieces. This process is essential as it breaks down the larger fibers into smaller, more manageable pieces.

Finally, the shredded textiles are sorted by type and size to ensure that they are sent to the appropriate recycling facility. Some textiles may be sent directly to a textile mill for further processing, while others may be sent to a paper mill or a plastic recycling facility.

Benefits of Automotive Interior Textiles Recycling: Recycling automotive interior textiles has numerous benefits beyond just reducing waste. Here are some of the key advantages:

-

Environmental Benefits: The recycling process reduces the amount of waste that ends up in landfills. By converting textiles into new products, we can significantly decrease the amount of raw material needed for production. Additionally, the process eliminates the need for new raw materials, which helps to mitigate greenhouse gas emissions associated with deforestation and mining.

-

Economic Benefits: Recycling automotive interior textiles creates jobs in the recycling industry. This sector employs individuals who specialize in sorting, shredding, and processing textiles. Furthermore, the creation of new products from recycled textiles can generate revenue for businesses involved in the recycling process.

-

Energy Efficiency: Recycling textiles requires less energy than producing new products from raw materials. This is because textiles are already processed and ready for use, whereas new products must be manufactured from raw materials. Therefore, recycling textiles can help to conserve energy and reduce greenhouse gas emissions.

-

Sustainability: Recycling automotive interior textiles promotes sustainability by reducing waste and preserving natural resources. By using recycled materials, we can reduce our dependence on non-renewable resources and minimize the impact of our consumption on the environment.

Case Study: One company that has successfully implemented a recycling program for automotive interior textiles is Terracycle. Terracycle is a global leader in textile recycling, providing consumers with access to sustainable, eco-friendly products made from recycled materials. Through its partnership with automotive manufacturers, Terracycle has been able to repurpose automotive interior textiles into new products such as clothing, furniture, and home decor.

By partnering with car manufacturers, Terracycle has been able to develop innovative solutions that allow for the recycling of automotive textiles. For example, one solution involves using recycled textiles to create car seats that are both comfortable and environmentally friendly. Another solution involves using recycled textiles to make car interiors more sustainable by reducing the use of synthetic materials.

Conclusion: Recycling automotive interior textiles is not only good for the environment but also economically beneficial. By reducing waste and generating revenue through recycling, we can create a more sustainable future for ourselves and future generations. As we continue to embrace the principles of sustainability and reduce our dependence on non-renewable resources, it is imperative that we prioritize the recycling of automotive interior textiles. By doing so, we can contribute to a healthier planet and a brighter future for all.

随着汽车行业的快速发展,汽车内衬纺织品的使用量也在不断增加,随着人们对环保意识的提高,汽车内衬纺织品的回收变得尤为重要,本文将围绕汽车内衬纺织品回收的主题,从多个角度进行深入探讨。

汽车内衬纺织品回收的重要性

- 环保意义:回收汽车内衬纺织品有助于减少环境污染,降低资源浪费。

- 经济价值:回收后的纺织品可以再次利用,减少生产成本,提高经济效益。

汽车内衬纺织品回收的现状与挑战

- 现状:随着汽车行业的快速发展,汽车内衬纺织品的使用量不断增加,但相应的回收率却不尽如人意。

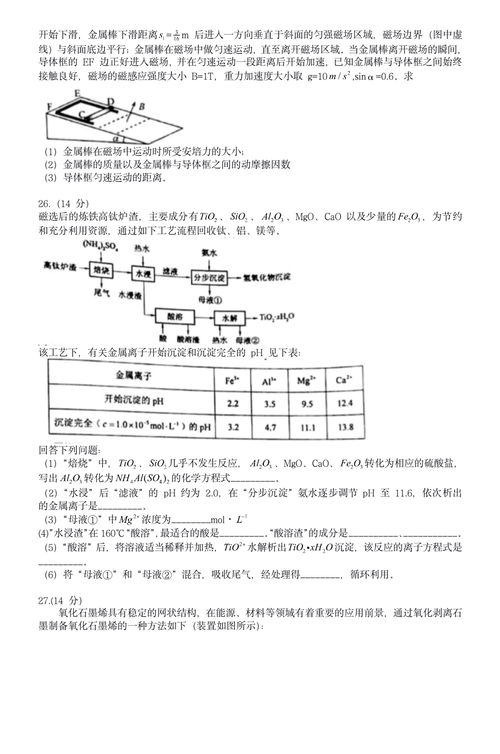

- 挑战:一是缺乏有效的回收渠道和政策支持;二是回收过程中的技术和管理问题。

案例分析

某汽车制造公司的成功实践

某汽车制造公司积极响应环保政策,建立了完善的内衬纺织品回收体系,他们通过与供应商合作,建立专门的回收渠道,确保回收的纺织品能够得到有效的处理和利用,公司还投入大量资金进行技术研发,提高回收过程中的技术和管理水平,经过一段时间的努力,该公司的回收率得到了显著提升,实现了经济效益和环境效益的双赢。

回收过程中的技术和管理问题

在回收过程中,仍存在一些技术和管理问题,部分地区的回收站点设备陈旧、管理不规范,导致回收效率低下,一些企业缺乏对回收价值的评估和再利用策略的制定,也影响了回收工作的开展。

汽车内衬纺织品回收的实践方法与建议

-

实践方法:建立完善的回收体系、加强宣传教育、提高技术水平和管理水平,加强与供应商的合作,确保回收的纺织品能够得到有效的处理和利用,政府和企业应出台相关政策,鼓励和支持汽车内衬纺织品的回收工作。

-

建议:

(1)加强政策引导和支持:政府应出台相关政策,鼓励和支持汽车内衬纺织品的回收工作,为企业的回收工作提供政策保障。

(2)推广先进的回收技术和设备:企业应加大投入,推广先进的回收技术和设备,提高回收效率和质量。

(3)加强宣传教育:通过宣传教育,提高公众对汽车内衬纺织品回收的认识和重视程度。

汽车内衬纺织品回收是一项重要的环保工作,对于实现可持续发展具有重要意义,通过建立完善的回收体系、加强政策引导和支持、推广先进的回收技术和设备、加强宣传教育等措施,可以有效提高汽车内衬纺织品的回收率,实现经济效益和环境效益的双赢,企业也应积极承担社会责任,为推动汽车行业的可持续发展做出贡献。

Articles related to the knowledge points of this article:

The Story of Double Connect Textiles:A Multinational Textile Company

Nantong Mingxin Lier Textiles:A Review

The Story of a Textile Merchant in the Wenjiang Family Business