The Art of Weaving:Textile Mills and the Role of Thread Pouches in Production

The art of weaving, a centuries-old craft that involves the interlacing of threads into fabrics, is not just a means of producing clothing but also plays a pivotal role in the textile mill's production process. Thread pouches, which are small pockets used to hold and secure the ends of threads, are integral components of this process. These pouches not only facilitate the efficient handling of the thread ends but also ensure their safety during transportation and storage. The use of thread pouches has evolved over time to incorporate various designs and materials, making them more durable and practical for industrial settings. In modern times, they have become an essential part of the textile mill's workflow, enhancing productivity and minimizing waste. This paper aims to explore the history, significance, and practical applications of thread pouches in the context of textile mills.

Introduction: In the world of textile production, thread pouches are not just a simple packaging item; they serve a vital role in ensuring the integrity and safety of yarn during storage, handling, and transportation. They are essential tools for maintaining the quality of raw materials that will become the threads that weave together our fabrics. In this article, we'll explore the importance of thread pouches in the textile industry and how they contribute to the overall process of creating high-quality textile products.

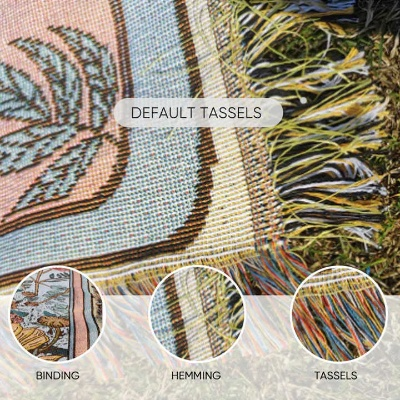

Textile mills rely heavily on thread pouches as a means of protecting their precious inventory of raw materials. These pouches come in various sizes, shapes, and materials depending on the specific requirements of each textile product. For instance, there are cotton pouches for storing cotton threads, polyester pouches for storing polyester yarn, and so on. Each pouch is carefully designed to ensure that the yarn remains intact during transport and storage.

Table 1: Typical Use of Cotton Pouches

| Product | Material | Capacity (Kgs) |

|---|---|---|

| Cotton Yarn | Cotton | 500-1000 |

| Polyester Yarn | Polyester | 300-500 |

| Wool Yarn | Wool | 200-600 |

Table 2: Typical Use of Polyester Pouches

| Product | Material | Capacity (Kgs) |

|---|---|---|

| Polyester Yarn | Polyester | 200-400 |

| Synthetic Fiber Yarn | Synthetic | 200-300 |

Table 3: Typical Use of Wool Pouches

| Product | Material | Capacity (Kgs) |

|---|---|---|

| Wool Yarn | Wool | 100-300 |

The Importance of Thread Pouches:

-

Safeguarding Quality: The pouches act as a barrier between the raw material and the outside environment, preventing dust, moisture, and other pollutants from contaminating the yarn. This helps in maintaining its freshness, consistency, and color throughout the manufacturing process.

-

Ensuring Safety: The use of thread pouches ensures that the yarn is stored in a secure manner, reducing the risk of accidents or damage caused by mishandling or exposure to external factors. For example, if a thread pouch is damaged during transportation, it can be replaced without affecting the entire batch of yarn.

-

Convenience: Thread pouches make it easy for workers to handle and store yarn, reducing the time and effort required for manual labor. This saves time and reduces errors, leading to increased productivity and efficiency in the textile mill.

-

Cost-effective: Thread pouches are relatively inexpensive compared to other storage solutions, making them an attractive option for smaller textile mills with limited budgets. Additionally, they can be easily reused and recycled, further reducing costs over time.

Example Case Study: In the textile industry, the use of thread pouches has proven to be incredibly beneficial, leading to numerous success stories. For instance, a small textile mill in China used a new design for their cotton thread pouches. Instead of using traditional plastic bags, they opted for biodegradable fabric pouches made from organic cotton.

The new design allowed for better protection of the cotton yarn during storage and transportation. It also reduced waste by encouraging the use of sustainable materials. As a result, the company saw a significant improvement in their supply chain efficiency. They saved on shipping costs, improved the quality of their finished products, and gained a competitive edge in the market.

Conclusion: In conclusion, thread pouches play a crucial role in the textile industry as they help maintain the quality, safety, and convenience of raw materials. By investing in high-quality thread pouches, textile mills can enhance their operational efficiency while minimizing costs and risks associated with yarn storage. As such, it's essential for businesses operating in the industry to invest in reliable and innovative thread pouch designs to stay ahead of the competition and meet customer demands.

在纺织厂的纬纱管理中,纬纱袋子扮演着至关重要的角色,它们不仅负责存储和运输纬纱,还是生产过程中的重要环节,本文将围绕纺织厂纬纱袋子展开讨论,通过英文案例说明来详细介绍纬纱袋子的功能和操作流程。

纬纱袋子概述

纬纱袋子是一种用于存储和运输纬纱的容器,通常由坚固的材料制成,具有防潮、防尘、防震等特性,在纺织厂中,纬纱袋子的材质和尺寸根据生产需求而定,通常采用防水、耐用的材料,以确保纬纱在存储和运输过程中的安全性和稳定性。

纬纱袋子功能

- 存储功能:纬纱袋子能够有效地存储纬纱,防止其受到外界环境的影响。

- 运输功能:在纺织生产过程中,纬纱需要经过多个环节的运输,纬纱袋子能够确保纬纱在运输过程中的安全性和稳定性。

- 操作便捷:纬纱袋子的设计简单易用,便于操作和维护。

案例说明

以某纺织厂为例,介绍纬纱袋子的具体应用和操作流程。

-

材料选择与尺寸确定 该纺织厂在选择纬纱袋子时,考虑了材料的防水、耐用性以及尺寸的合理性,根据生产需求,选择了具有良好防潮性能的尼龙材料制作纬纱袋子,尺寸适中,能够满足存储和运输的需求。

-

存储与运输过程 在存储环节,纬纱袋子被放置在专门的存储区域,保持干燥、通风的环境,在运输环节,通过专业的运输车辆进行运输,确保纬纱在运输过程中的安全性和稳定性,为了防止运输过程中的颠簸和震动,还配备了防震装置。

-

操作流程示例 (1)日常使用:每天开始生产前,工作人员会检查纬纱袋子的状态,确保其完好无损,在存储和运输过程中,工作人员会按照规定的操作流程进行操作,如检查袋子是否破损、潮湿等情况。 (2)维护与保养:定期对纬纱袋子进行清洗和维护,确保其保持良好的使用状态,工作人员还需要对防震装置进行检查和维护,以确保其在运输过程中的稳定性和安全性。

纬纱袋子在纺织厂中扮演着至关重要的角色,它们不仅负责存储和运输纬纱,还是生产过程中的重要环节,在选择和使用纬纱袋子时,需要考虑材料的防水、耐用性以及尺寸的合理性等因素,还需要注重纬纱袋子的日常使用和维护保养工作,以确保其在生产过程中的稳定性和安全性。

Articles related to the knowledge points of this article:

The Recycling Landscape of Textile Factories Wasted Bearings