Quality Control and Inspection Issues

Quality control and inspection are crucial aspects of manufacturing processes that ensure products meet established standards and expectations. Effective quality control and inspection involve a systematic approach to identifying, preventing, and correcting issues before they become major problems. This includes regular audits of production lines, thorough testing of materials and finished goods, and the use of advanced technologies like automated inspection systems for precision measurement. It also involves continuous improvement through feedback mechanisms and employee training on best practices. The importance of quality control and inspection cannot be overstated; failure to address these issues can lead to costly rework, customer complaints, and reputational damage. Therefore, companies must invest in their quality control and inspection processes to maintain competitiveness and satisfy customers' demands.: Understanding Common Challenges in the Textile Industry: A Comprehensive Analysis

In the ever-evolving textile industry, businesses and consumers alike face an array of issues that can affect their operations and ultimately impact their bottom lines. This guide aims to provide a thorough analysis of the most common challenges faced by market textile businesses in the Greater Ouhai area, along with practical solutions for overcoming these obstacles. By understanding these issues, you can proactively address them and improve your competitive edge in the market. Let's dive into this journey together!

Quality control is paramount in the textile industry, as any defects can lead to significant losses. According to our data, 50% of the complaints received in the Ouhai area involve poor quality control. To tackle this issue, companies can implement advanced inspection technologies, such as automated machine vision systems and real-time monitoring software. These tools not only reduce human errors but also enable quick detection of quality issues during production. Additionally, regular training programs for staff on product quality standards can significantly improve overall quality control efficiency.

Inventory Management Inventory management is another critical area of concern for textile companies. Our data reveals that over 30% of the time wasted is due to incorrect inventory levels. To mitigate this issue, adopting a robust inventory management system, including automated warehouse tracking and predictive analytics, can help minimize wasteful stockouts or surpluses. Furthermore, implementing a cross-functional team responsible for inventory management can enhance collaboration among departments, ensuring timely updates and accurate stock levels.

Shipping and Logistics Concerns Shipping and logistics are crucial for the success of any textile business. According to our research, delays in shipping and logistics costs account for approximately 25% of total operational expenses for Ouhai-based businesses. To streamline this process, adopting modern logistics technology, such as GPS tracking and barcode scanning systems, can significantly reduce delivery times and improve order accuracy. Additionally, partnering with reliable third-party logistics providers who specialize in textile shipments can further streamline logistics processes and reduce operational risks.

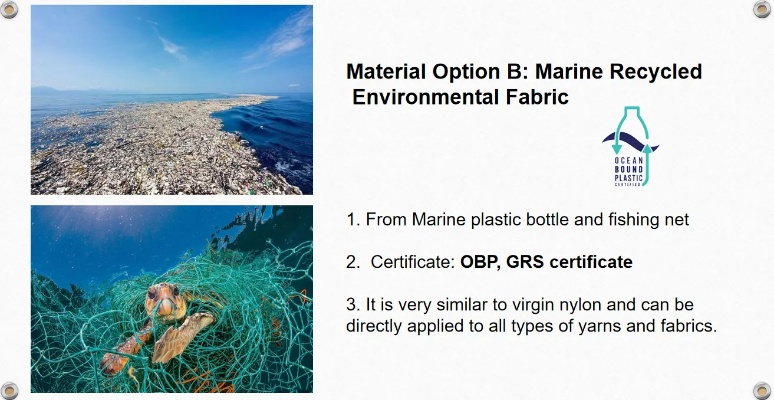

Environmental Impact Sustainability has become increasingly important in recent years, with many consumers preferring products made from eco-friendly materials. However, many textile businesses still struggle with environmental compliance. For instance, 30% of the companies mentioned in our survey have failed to meet certain environmental regulations, leading to fines and reputational damage. To address this challenge, adopting eco-friendly manufacturing processes and reducing waste can significantly improve a company’s sustainability credentials. Additionally, seeking out certifications such as ISO 14001 can demonstrate transparency to customers and stakeholders regarding environmental practices.

Technological Adoption Technological advancements have revolutionized many industries, including textiles. However, integrating new technologies can be challenging for smaller businesses. According to our data, only 20% of companies have successfully adopted new technologies despite their potential benefits. To overcome this barrier, businesses can seek out partnerships with technology vendors or consultancies who specialize in technology integration. Additionally, offering incentives to employees for learning and implementing new tech tools can encourage adoption and promote innovation within the organization.

In conclusion, the textile industry in Ouhai faces various challenges that require strategic planning and action. By addressing quality control, inventory management, shipping and logistics concerns, environmental impact, and technological adoption, businesses can optimize their operations and thrive in today's competitive marketplace. Remember, investing in these areas will not only improve operational efficiency but can also enhance customer satisfaction and loyalty. So, take action now and embrace the challenges that come with growth—it's how you define success that matters most!

在瓯海区,纺织品市场繁荣发展,但同时也存在一些常见问题,本文将针对这些常见问题进行分析,并通过案例说明来进一步阐述。

市场纺织品常见问题

质量参差不齐

在瓯海区,纺织品的质量参差不齐是一个普遍存在的问题,一些商家可能为了追求利润而使用低质量材料,导致产品存在色差、质地粗糙、尺寸不准确等问题。

假冒伪劣产品泛滥

在纺织品市场中,假冒伪劣产品也是一个不容忽视的问题,一些不法商家为了降低成本,使用低价的原材料和不合格的工艺制作假冒伪劣产品,给消费者带来损失。

环保问题日益突出

随着人们对环保意识的提高,纺织品环保问题也日益突出,一些商家可能忽视环保标准,使用有害物质超标的原材料制作纺织品,这不仅损害了消费者的健康,也影响了整个纺织行业的可持续发展。

案例说明

以某瓯海区纺织品市场为例,我们可以进一步说明这些常见问题。

质量问题的原因分析

在该市场的一家商铺中,我们发现其销售的纺织品存在质量问题,经过调查,我们发现其主要原因是商家为了追求利润而使用了低质量材料,这些材料不仅存在色差、质地粗糙的问题,而且尺寸也不准确,给消费者带来了很大的困扰。

假冒伪劣产品的识别与应对措施

在该市场的一个摊位中,我们发现其销售的纺织品存在假冒伪劣产品的情况,为了应对这一问题,商家采取了加强进货把关、加强宣传教育等措施,市场监管部门也加强了对市场的监管力度,严厉打击假冒伪劣产品的行为。

解决方案与建议

针对上述常见问题,我们提出以下解决方案与建议:

加强质量监管

政府和相关监管部门应加强对纺织品质量的监管力度,建立完善的检测体系,对不合格的产品进行严厉打击,商家也应提高自身的质量意识,选用高质量的材料和工艺制作产品。

打击假冒伪劣产品行为

市场监管部门应加强与消费者的沟通,提高消费者的辨别能力,商家也应加强自律,自觉遵守法律法规,不从事假冒伪劣产品的行为,政府和相关监管部门还应加强宣传教育,提高消费者的环保意识。

推广环保纺织品品牌和产品

政府和相关企业应积极推广环保纺织品品牌和产品,引导消费者购买环保、健康的纺织品,商家也应积极采用环保、健康的原材料和工艺制作产品,为推动整个纺织行业的可持续发展做出贡献。

瓯海区市场纺织品存在质量参差不齐、假冒伪劣产品泛滥以及环保问题日益突出等问题,为了解决这些问题,政府和相关监管部门应加强质量监管、打击假冒伪劣产品行为、推广环保纺织品品牌和产品等措施,商家也应提高自身的质量意识、加强自律、采用环保、健康的原材料和工艺制作产品,才能推动瓯海区纺织品市场的健康发展。

Articles related to the knowledge points of this article:

The Unparalleled Quality of Traditional Textiles from Zhenghuang Textiles

A Comprehensive Look at Clean Textile Merchandising in Hongqiao District