The Art of Threading:A Comprehensive Guide to Seam Weaving in Textile Mills

: The Art of Threading: A Comprehensive Guide to Seam Weaving in Textile Mills,Abstract: This comprehensive guide aims to provide a detailed understanding of the art of threading, which is integral to the production process of textile mills. It covers the various techniques and methods used to thread yarns onto looms, as well as the importance of proper threading practices in ensuring consistent and high-quality fabrics. The guide also highlights the challenges faced by weavers and their solutions, highlighting the significance of maintaining accurate measurements and using specialized tools for optimal results. By following this guide, readers will gain a deeper appreciation for the intricate details involved in seam weaving and the critical role it plays in the overall success of textile mills.

Introduction: In the world of textiles, the art of weaving is not just a mechanical process; it's an intricate dance that requires precision and skill. Among the many steps involved in creating textiles, seaming is one of the most crucial. It involves joining two or more fabrics together using thread, often referred to as "seam threads," which are woven into the fabric. In this guide, we will explore the various techniques used in seaming, including the importance of proper thread selection, the role of the seam weaver, and how to maintain consistent seams throughout the production process.

Part One: Seam Weaving Techniques

Seam weaving can be categorized into several methods depending on the type of fabric being seamed and the desired outcome. Here are some common techniques:

-

Over-the-edge (OTE) Seam Weaving: This technique involves sewing over the edge of the fabric, leaving a small gap for turning. It's commonly used for garments such as shirts and dresses.

-

Under-the-edge (UTE) Seam Weaving: In this method, the seam is sewn inside the fabric, creating a neat and tidy look. It's ideal for items like tablecloths and curtains.

-

Stitched Seam: This is a simple but effective method where a needle is used to stitch the seam together. It's suitable for both OTE and UTE seams.

-

Needle-turning Seam: Also known as a French seam, this technique involves turning the fabric over while sewing. It creates a crisp, clean finish and is commonly used for denim jeans.

-

Binding Seam: This is a decorative seam that adds texture and interest to the fabric. It's often used for finishing upholstered furniture or adding embellishments to clothing.

-

Machine-stitched Seam: This method uses a machine to sew the seam, making it faster and more efficient. It's particularly useful for large-scale production.

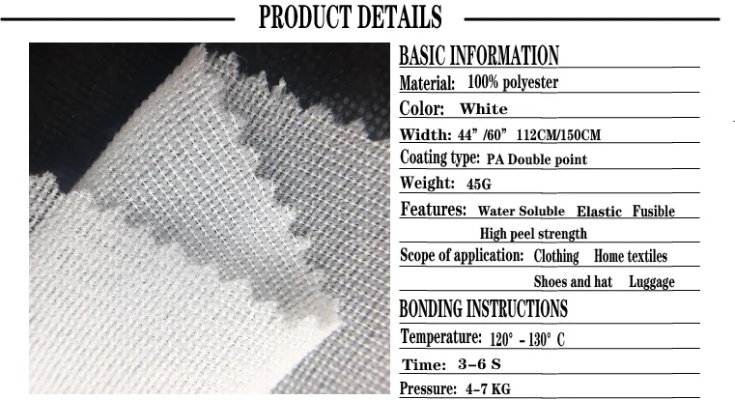

Part Two: Importance of Proper Thread Selection

The quality of the thread used in seaming plays a significant role in the overall appearance and durability of the finished product. Here are some factors to consider when selecting thread:

-

Type of Thread: There are different types of thread available, each with its own properties. For instance, polyester thread is strong and resistant to wear and tear, while cotton thread is softer and absorbent.

-

Thread Thickness: The thickness of the thread affects the strength and stretchiness of the fabric. Thicker threads are stronger and can withstand more wear and tear, while thinner threads may be more delicate and prone to fraying.

-

Color Coating: Some threads come with a color coating that enhances their appearance. However, it's important to ensure that the coating doesn't interfere with the thread's strength or durability.

-

Durability: The thread should be able to withstand the conditions of use, such as washing, drying, and repeated use.

Part Three: Seam Weaver's Roles

The seam weaver is responsible for ensuring that the seams are consistently made with high quality and meet the standards set by the manufacturer. Here are some key roles they play:

-

Knowledgeable: The seam weaver should have a thorough understanding of the materials and techniques used in seaming. They should also be familiar with any special requirements or guidelines that may apply to a particular project.

-

Precision: Seam weavers must be extremely precise in their work, paying attention to details such as thread tension, seam width, and stitch length.

-

Quality Control: They must monitor the quality of the seams throughout the production process and take corrective action if necessary.

-

Communication: Seam weavers need to communicate effectively with other team members, including pattern makers, dyers, and finishers, to ensure that all aspects of the project are aligned.

Part Four: Maintaining Consistent Seams

To ensure consistent seams throughout the production process, there are several practices that can be followed:

-

Standardized Workflow: Having a standardized workflow can help reduce errors and improve consistency. This includes setting up a system for measuring and cutting fabric, preparing tools, and following predefined procedures.

-

Training: Providing regular training to seam weavers can help them develop skills and knowledge needed to produce high-quality seams.

-

Quality Checks: Continuous quality checks during the production process can help catch errors early and prevent defects from reaching the final product.

-

Use of Technology: Advances in technology, such as computer-aided design (CAD) software and automated equipment, can help streamline the seaming process and improve consistency.

Conclusion: Seaming is an essential part of the textile manufacturing process, and it requires both technical expertise and attention to detail. By understanding the various techniques used in seaming, selecting high-quality thread, delegating responsibilities effectively, and maintaining consistent practices, textile mills can produce high-quality products that meet customer expectations. As with any craft, the art of seaming requires patience, practice, and continuous improvement to achieve excellence.

纺织厂接缝盘简介

在纺织行业中,接缝盘是一个重要的工具,用于精确控制纺织品的接缝质量,它不仅关系到产品的外观和耐用性,还影响着生产效率和成本,本文将围绕纺织厂接缝盘展开讨论,并提供相关案例说明。

接缝盘的结构与功能

接缝盘的结构

接缝盘通常由多个部件组成,包括接缝板、压脚、夹具等,接缝板是接缝盘的核心部件,用于承受压力和固定纺织品,压脚用于施加压力,确保接缝平整,夹具则用于固定纺织品,确保接缝位置的准确性。

接缝盘的功能

接缝盘的主要功能是控制纺织品的接缝质量,确保产品外观和耐用性,通过精确控制接缝的宽度、深度和角度,可以确保纺织品在生产过程中的稳定性和一致性,接缝盘还可以提高生产效率,减少人工操作误差,降低生产成本。

接缝盘的使用与维护

在使用接缝盘时,需要注意以下几点:

- 选择合适的接缝盘型号和规格,根据纺织品类型和要求进行选择。

- 正确安装和使用夹具和压脚,确保接缝位置的准确性。

- 定期检查接缝盘的状态,及时维修和更换磨损部件。

案例分析

以某纺织厂为例,介绍接缝盘的使用与维护情况,该纺织厂采用先进的接缝盘技术,实现了高质量的纺织品生产。

接缝盘的使用情况

该纺织厂采用先进的接缝盘技术,严格控制接缝质量,在生产过程中,接缝盘能够精确控制纺织品接缝的宽度、深度和角度,确保产品外观和耐用性,该厂还采用了自动化生产线,提高了生产效率。

接缝盘的维护情况

该纺织厂注重接缝盘的维护工作,定期检查接缝盘的状态,及时维修和更换磨损部件,该厂还采用了先进的维护技术,提高了接缝盘的可靠性和使用寿命,该厂还注重员工培训,提高了员工对接缝盘的认知和使用能力。

使用表格说明

以下是使用表格说明纺织厂接缝盘的一些关键信息:

| 参数 | 描述 | 数据来源 |

|---|---|---|

| 接缝盘型号 | 根据纺织品类型和要求进行选择 | 实际使用情况 |

| 结构 | 接缝板、压脚、夹具等 | 实际使用情况 |

| 功能 | 控制纺织品接缝质量,确保产品外观和耐用性 | 相关文献资料 |

| 使用与维护 | 选择合适的型号和规格,正确安装和使用夹具和压脚,定期检查和维护 | 实际使用和维护情况 |

| 案例分析 | 该纺织厂采用先进的接缝盘技术,实现了高质量的纺织品生产 | 相关案例资料 |

结论与建议

纺织厂接缝盘是控制纺织品接缝质量的重要工具,在使用和维护过程中,需要注意选择合适的型号和规格、正确安装和使用夹具和压脚、定期检查和维护等方面,还需要注重员工培训和技术更新,提高接缝盘的可靠性和使用寿命,建议纺织企业加强接缝盘的研发和应用,提高产品质量和生产效率。

Articles related to the knowledge points of this article:

The Story of Huatian Textile Factory

The Height of Yangs Textile Factory

The Art of Textile Factory Plastic Belt Making

The Risk of the Ningjin Textile Factory