Exploring the Plastic Possibilities for Textiles

In recent years, the development of textiles has witnessed a significant increase in their versatility and functionality. The use of plastic materials in textile production has opened up new possibilities for designers to create innovative and sustainable clothing. This paper aims to explore the potential of plastics in textiles and discusses the challenges and opportunities associated with this trend.,The integration of plastics into textiles has been driven by the need for lighter, stronger, and more durable fabrics. Plastic fibers have been used to create stretchy, elastic, and waterproof fabrics that are perfect for outdoor activities such as hiking, camping, and swimming. Additionally, plastic-based materials offer eco-friendly alternatives to traditional textiles, reducing waste and promoting sustainability.,Despite the benefits of using plastic in textiles, there are also concerns about the environmental impact of these materials. The production and disposal of plastic fibers require energy and resources, which can contribute to pollution and climate change. Therefore, it is essential to consider the long-term effects of using plastic in textiles and develop strategies to minimize their environmental footprint.,In conclusion, the use of plastic materials in textiles presents both opportunities and challenges. By exploring the potential of plastics in textiles, designers can create innovative and sustainable clothing that meet the needs of modern society. However, it is crucial to address the environmental impact of plastic usage and develop sustainable practices to ensure the long-term viability of this trend.

Introduction Textiles, a vital component of our daily lives, are made from a variety of materials, but plastic has recently emerged as a compelling contender in this field. From innovative designs to eco-friendly practices, plastic is increasingly being used in textile production, offering both practicality and sustainability benefits. In this talk, we'll explore the different types of plastic that can be incorporated into textiles, their applications, and the potential challenges they present. Let's dive into the world of plastic-textile hybrids!

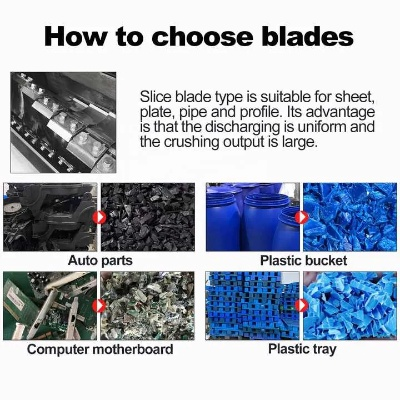

Types of Plastic Used in Textiles

-

Polyethylene (PE)

- Application: PE is commonly used as a film or fabric for packaging, such as food and beverage containers, and it's also used in the manufacture of shower curtains and window coverings.

- Case Study: PepsiCo uses PE films for its bottle caps, which not only protect the contents but also contribute to recycling efforts by being recyclable.

-

Polypropylene (PP)

- Application: PP is often used for durable outdoor clothing, bags, and other household items due to its resistance to wear and tear.

- Case Study: Patagonia uses recycled PP to create its iconic backpacks, showcasing the versatility of this versatile plastic.

-

Polystyrene (PS)

- Application: PS is commonly used for packaging foam, furniture, and toys. It's also used in the production of shower curtains and upholstery.

- Case Study: The American Toy Association promotes PS as a sustainable alternative to traditional wood products, highlighting the environmental benefits of using this plastic.

-

Polyamide (PA)

- Application: PA is used in the production of carpets, upholstery, and other soft furnishings due to its durability and resilience to stains.

- Case Study: Bed Bath & Beyond uses PA in their carpets, showcasing how this material can add texture and style to indoor spaces while also being recyclable.

-

Polycarbonate (PC)

- Application: PC is often used in the manufacture of automotive parts, such as windshields and interior trims, due to its strength and impact resistance.

- Case Study: Ford Motor Company uses PC in the construction of its vehicles, demonstrating the potential of this plastic in high-performance applications.

Potential Challenges and Opportunities While plastic offers significant advantages in terms of cost-effectiveness and ease of production, there are also concerns about its environmental impact. For instance, the use of certain plastics can release harmful chemicals into the environment during manufacturing processes or when they decompose. However, advancements in recycling and composting technologies can mitigate these risks.

Moreover, consumers have become more aware of the ethical implications of using plastic in textiles. Many brands are now incorporating recycled or sustainably sourced materials into their collections, signaling a shift towards a circular economy. This shift towards more responsible production methods presents an exciting opportunity for the textile industry to evolve and adapt to changing consumer preferences.

Conclusion The integration of plastic into textiles is not just about meeting the demands of modern society; it's also about fostering a more sustainable future. By exploring the various types of plastic available and their applications, we can better understand the potential benefits and challenges associated with this emerging trend. As we continue to push the boundaries of what's possible in the textile industry, let's embrace the opportunities presented by plastic-textile hybrids while also being mindful of the environmental impacts.

在探讨哪种塑料可以做纺织品时,我们可以从多个角度来分析,以下是一篇关于塑料与纺织品结合的英文口语化内容,并附上英文案例说明。

塑料作为一种广泛应用的材料,其在纺织品的制作中扮演着重要的角色,不同的塑料材料具有不同的物理性质和化学特性,因此它们可以被用于不同的纺织品制作中,本文将通过案例分析,探讨哪些塑料可以做纺织品。

塑料种类及其特性

- 聚乙烯(PE):聚乙烯是一种常见的塑料材料,具有优良的耐热性、耐寒性、抗冲击性等特性,使其成为制作各种纺织品的理想选择。

- 聚丙烯(PP):聚丙烯也是一种常用的塑料材料,具有轻质、高强度、耐腐蚀等特性,使其在制作轻便衣物和装饰性纺织品方面具有优势。

- 聚苯乙烯(PS):聚苯乙烯是一种硬质塑料,主要用于制作工业制品和装饰性装饰品,不适用于制作纺织品。

案例分析

聚乙烯案例:

某品牌服装公司使用聚乙烯制作夏季衣物,由于聚乙烯具有良好的透气性和吸湿性,使得其制成的衣物轻盈且透气性好,适合夏季穿着,聚乙烯的耐用性和抗老化性能也使其成为制作运动服装的理想选择。

家居装饰品公司使用聚乙烯制作窗帘和地毯,聚乙烯的柔软性和可塑性使其成为制作窗帘和地毯的理想材料,可以制作出各种形状和纹理的制品,由于其环保性质,聚乙烯制品也符合现代消费者对环保产品的需求。

其他塑料案例:

某些特殊用途的塑料也可以用于纺织品制作,某些塑料薄膜可以用于制作手提包、鞋垫等装饰性纺织品,某些塑料板材也可以用于制作窗帘、床单等家居用品。

塑料与纺织品的结合应用

- 工艺特点:不同塑料材料具有不同的工艺特点,使得它们可以应用于不同的纺织品制作中,聚乙烯的轻质和耐用性使其适合用于制作轻便衣物和装饰性纺织品;而聚丙烯的高强度和抗老化性能则使其适合用于制作运动服装和家居用品。

- 应用领域:随着科技的发展和人们生活水平的提高,塑料与纺织品的结合应用领域也在不断扩大,在服装、家居用品、装饰品等领域,都可以看到塑料与纺织品的结合应用。

不同的塑料材料具有不同的物理性质和化学特性,它们可以被用于不同的纺织品制作中,在选择适合的塑料材料时,需要考虑其工艺特点、应用领域等因素,随着科技的发展和人们生活水平的提高,塑料与纺织品的结合应用领域也在不断扩大,未来将会有更多的创新和发展。

Articles related to the knowledge points of this article:

Limitations in the Collection of Waste Textiles:A Call to Action