The Innovative Journey of a Small Textile Factory:From Challenges to Success

The small textile factory, with its innovative spirit and relentless pursuit of excellence, has successfully transformed from a struggling enterprise to a thriving success story. The journey began with the factory's founder's visionary approach to innovation, which led to the development of a unique production process that not only improved efficiency but also enhanced product quality.,However, this path was not without obstacles. The factory faced challenges such as limited resources, outdated technology, and a lack of market awareness. Despite these challenges, the factory's team persevered, constantly seeking new solutions and adapting to changing circumstances.,Through hard work and dedication, the factory achieved remarkable success. It became a leader in its industry, producing high-quality products that were sought after by customers around the world. The factory's innovative approach to production and marketing strategies helped it establish itself as a trusted brand in the market.,This journey serves as an inspiration for other small businesses looking to succeed in their industries. It shows that with determination, creativity, and a willingness to adapt to change, even the smallest enterprises can achieve great success.

Introduction: In the world of textile manufacturing, small factories often face unique challenges that can either be opportunities or roadblocks to success. At our local small textile factory, we've seen firsthand how innovation and resilience can turn these challenges into stepping stones towards growth and sustainability. This journey is not just about producing quality products; it's about creating a legacy that values innovation, community, and environmental responsibility.

I. Understanding the Environment: A Case Study Our factory has always been mindful of its impact on the environment. We started by conducting regular audits to measure our carbon footprint and identify areas for improvement. Our commitment to sustainability led us to adopt eco-friendly practices such as using recycled materials and implementing energy-efficient machinery.

We also partnered with local communities to support sustainable initiatives. For example, we collaborated with a local cooperative that grows organic cotton, providing them with access to high-quality yarns and fabrics. This partnership not only benefited the cooperative but also increased our brand's reputation for being a socially responsible company.

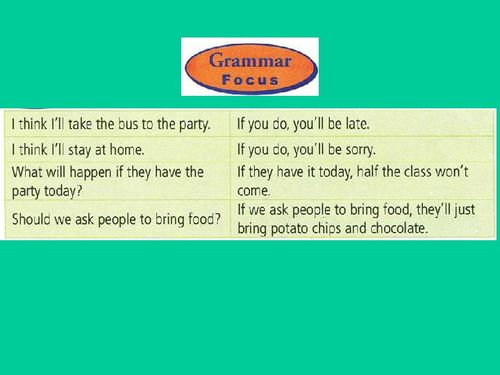

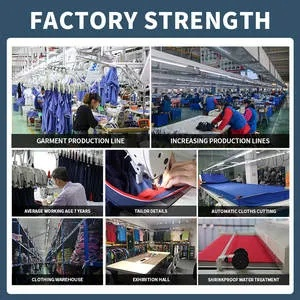

II. Innovation in Production: Technological Advancements In recent years, we have made significant investments in technology to improve our production processes. We introduced automated machines to reduce labor costs and increase efficiency. Additionally, we implemented a digital inventory management system that allows us to track our inventory more accurately and efficiently.

One innovative idea we implemented was a smart labeling system that helps us track the origin of our raw materials. By using blockchain technology, we can trace the journey of each piece of yarn from farm to factory, ensuring transparency and authenticity.

III. Embracing Change: Adapting to Market Trends The textile industry is constantly evolving, and our factory has had to adapt to stay ahead of the curve. We've embraced new technologies such as 3D printing and robotics to create intricate designs and patterns that were previously impossible to produce.

We's also adapted our supply chain to better respond to market demands. For instance, we now work closely with suppliers who specialize in sustainable materials, ensuring that our products meet the needs of conscious consumers.

IV. Building a Community: Collaboration and Sustainability At our small textile factory, we believe in the power of collaboration and sustainability. We regularly host workshops and training sessions for our employees to learn about sustainable practices and share best practices.

We also engage in various community projects, such as donating excess fabric to local shelters and supporting local farmers markets. These initiatives not only help us build a positive brand image but also foster a sense of belonging among our employees and the wider community.

Conclusion: Our small textile factory has come a long way since its inception. From facing challenges to turning them into opportunities, we've learned that innovation, sustainability, and collaboration are key to success. As we continue to grow and evolve, we remain committed to creating a brighter future for ourselves, our employees, and the communities we serve.

小纺织厂工厂是一个充满活力与创新的场所,它不仅生产出优质的纺织品,还为当地社区带来了就业机会和经济效益,我们深入了解这个工厂的运营模式、生产流程以及面临的挑战。

工厂运营模式

生产流程

小纺织厂工厂采用先进的生产技术,包括自动化生产线、智能监控系统等,确保产品质量和生产效率,在生产过程中,注重环保、节能和安全,采用绿色材料和环保工艺。

员工构成

工厂吸引了众多员工,包括熟练工人、技术工人和学徒等,员工队伍多元化,涵盖了各个年龄段和技能水平,工厂注重员工培训和发展,提供良好的工作环境和福利待遇。

生产特点

优质纺织品

小纺织厂工厂生产的纺织品质量上乘,品种丰富,满足不同客户的需求,工厂注重产品质量控制,采用严格的质量检测标准,确保产品符合国家标准和客户要求。

绿色环保

工厂注重环保理念,采用绿色材料和环保工艺,减少生产过程中的污染和浪费,工厂积极参与环保活动,推广绿色生产方式。

面临的挑战

市场竞争压力

随着市场竞争的加剧,小纺织厂工厂面临着来自国内外市场的竞争压力,为了保持竞争优势,工厂需要不断提高产品质量、降低成本、提高效率。

技术更新与升级

随着科技的不断进步,小纺织厂工厂需要不断更新技术和设备,提高生产效率和产品质量,工厂需要加强技术研发和创新,提高企业的核心竞争力。

案例分析

以某小纺织厂为例,介绍其在应对挑战、提高生产效率方面的成功经验,该工厂采用了先进的生产技术和管理模式,注重员工培训和发展,同时积极参与环保活动,在生产过程中,注重环保、节能和安全,采用绿色材料和环保工艺,该工厂还加强了与上下游企业的合作,提高了供应链的效率和稳定性,通过这些措施,该工厂在市场竞争中取得了较好的成绩。

小纺织厂工厂是一个充满活力和创新的地方,它不仅生产出优质的纺织品,还为当地社区带来了就业机会和经济效益,在面对市场竞争压力和技术更新与升级的挑战时,该工厂采取了多种措施来应对,该工厂注重员工培训和发展,积极参与环保活动,提高了企业的核心竞争力,该工厂将继续加强技术创新和管理创新,提高生产效率和产品质量,为当地社区和社会做出更大的贡献。

Articles related to the knowledge points of this article:

The Textile Factory Job Hunting Guide