The Essential Testing Requirements for Textiles

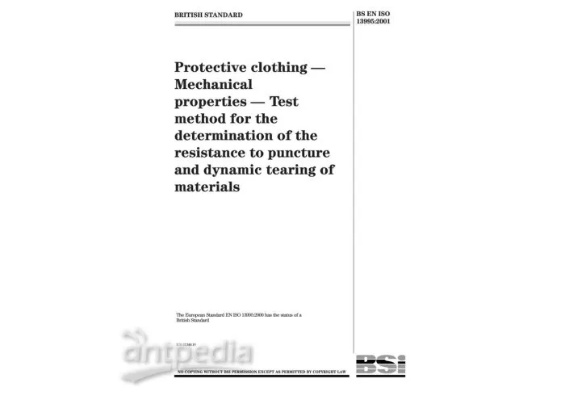

The essential testing requirements for textiles involve a series of rigorous processes aimed at ensuring the quality and durability of these materials. These tests are critical in determining whether a fabric meets specific standards, such as those set by international organizations like ISO or ASTM.,One common requirement is the determination of the fabric's weight per unit area, which is measured using a balance. This measurement allows for the calculation of various properties, including its density, thickness, and strength.,Another important test is the determination of the fabric's tear resistance, which involves measuring how much it can withstand before breaking. This test is performed using specialized equipment, such as a tearometer, to ensure that the fabric can withstand heavy use without becoming damaged or frayed.,In addition to these basic tests, there are more specialized tests that are conducted on specific types of textiles, such as those made from synthetic fibers or those designed for outdoor use. These tests help to identify any potential issues with the fabric's performance and ensure that it meets the intended purpose.

Textiles are an essential part of our daily lives, from clothing to home furnishings. They play a crucial role in protecting us from the elements and providing warmth and comfort. As such, it is important that textiles meet certain standards and undergo rigorous testing to ensure their quality and safety. In this article, we will explore some of the essential testing requirements for textiles.

Material Testing:

Before any textile can be produced, it must first pass material testing. This involves examining the raw materials used in the production process, such as cotton, wool, and synthetic fibers. Material testing ensures that the raw materials meet specific quality standards, including their composition, color, and texture. For example, a cotton fabric must have a minimum percentage of cotton fibers in order to be considered cotton-based.

Quality Control:

Once the materials have been processed, they must undergo quality control testing to ensure that they meet the required standards. This includes checking for defects such as holes, tears, and loose threads. Additionally, quality control tests can include measuring the fabric's weight, thickness, and density. For example, a sample of a t-shirt could be tested for its weight and thickness to ensure that it meets the required specifications.

Shrinkage Testing:

Textiles often shrink during washing or exposure to certain chemicals. Shrinkage testing is necessary to determine how much the fabric will shrink after washing and drying. This information is crucial for manufacturers to ensure that their products do not lose shape or become damaged during use. For example, a sample of a dress could be tested for its shrinkage rate to ensure that it does not lose its shape after being washed.

Flame Retardant Testing:

Textiles need to be flame retardant to prevent fires from spreading when they catch fire. Flame retardant testing involves evaluating the fabric's ability to resist burning and extinguish itself once it has caught fire. This testing is particularly important for fabrics used in outdoor settings, such as tents and outdoor furniture. For example, a sample of a tent could be tested for its flame retardant properties to ensure that it can withstand a fire without catching on fire.

Structural Strength Testing:

Textiles need to be structurally strong enough to withstand wear and tear over time. Structural strength testing involves evaluating the fabric's strength and durability by subjecting it to various stresses and strains. This testing is particularly important for high-wear items such as jeans and jackets. For example, a sample of a pair of jeans could be tested for its structural strength to ensure that it can withstand heavy wear and tear without breaking down.

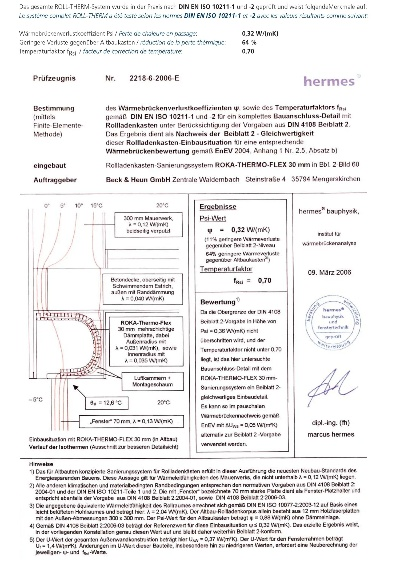

Certification:

Finally, textiles need to be certified to ensure that they meet certain standards and regulations. Certification involves passing various tests and evaluations to prove that the fabric meets specific quality and safety requirements. Certification helps consumers identify high-quality textiles and ensures that manufacturers comply with industry standards. For example, a sample of a shirt could be certified for its eco-friendly practices and sustainability goals.

In conclusion, textiles require several essential testing requirements to ensure their quality and safety. Material testing, quality control, shrinkage testing, flame retardant testing, structural strength testing, and certification all play a crucial role in ensuring that textiles meet the needs of consumers and industry standards. By following these testing requirements, manufacturers can produce high-quality textiles that provide comfort, protection, and style to people around the world.

在纺织品生产过程中,质量检测是确保产品符合标准的重要环节,本文将详细介绍纺织品需要做哪些检测项目,并通过案例分析来说明这些检测的重要性。

纺织品检测项目概述

- 物理性能检测:包括拉伸强度、弹性模量、耐磨性、色牢度等。

- 化学成分检测:包括纤维成分、染料成分、重金属含量等。

- 微生物检测:用于检测纺织品中是否存在有害微生物。

- 安全性能检测:如防火、防毒、防辐射等。

- 环境影响检测:评估纺织品对环境的影响,如环保认证等。

案例分析

以纺织品为例,说明不同检测项目的重要性:

某品牌纺织品检测项目

该品牌在生产过程中,对纺织品进行了全面的质量检测,其中包括物理性能检测、化学成分检测、微生物检测和环境影响检测,通过这些检测,确保了产品的质量符合国家标准,提高了消费者的信任度。

- 物理性能检测:该品牌对纺织品的拉伸强度、弹性模量进行了严格测试,确保产品的耐用性和舒适性。

- 化学成分检测:该品牌对纤维成分和染料成分进行了详细分析,确保产品的环保性和安全性,对重金属含量进行了严格控制,符合国家相关标准。

- 微生物检测:该品牌采用了先进的微生物检测技术,确保纺织品中不存在有害微生物,保障了消费者的健康安全。

- 环境影响检测:该品牌通过环保认证,证明其产品对环境的影响较小,符合可持续发展的要求。

具体检测项目及方法

- 物理性能检测:包括纤维长度、直径、均匀性、弹性模量等测试,具体方法包括拉伸试验、摩擦试验等。

- 化学成分检测:采用化学分析方法,如元素分析、色谱分析等,具体步骤包括样品制备、化学分析等。

- 微生物检测:采用无菌操作技术,对纺织品进行无菌处理,然后进行微生物培养和鉴定,采用实时监测技术,实时监控微生物的生长情况。

- 环境影响检测:采用环境影响测试仪器,对纺织品进行环境影响测试,包括温度、湿度、光照等环境因素测试,参考相关国家标准和行业标准进行评估。

纺织品的质量检测是确保产品质量的重要环节,通过全面的质量检测,可以确保产品的质量符合国家标准,提高消费者的信任度,对于环境影响较小的纺织品,可以更好地满足可持续发展的要求,在纺织品生产过程中,应该加强质量检测工作,提高产品质量水平。

就是关于纺织品需要做哪些检测的详细介绍,希望对您有所帮助,如果您需要更专业的解读或案例分析,请随时联系我们。

Articles related to the knowledge points of this article:

Springdale Textiles:A Journey into the World of Fabric and Fashion

Chinas Textile Trade Strength and Global Impact

The Transformative Journey of Guangdong Hanbo Textiles Company