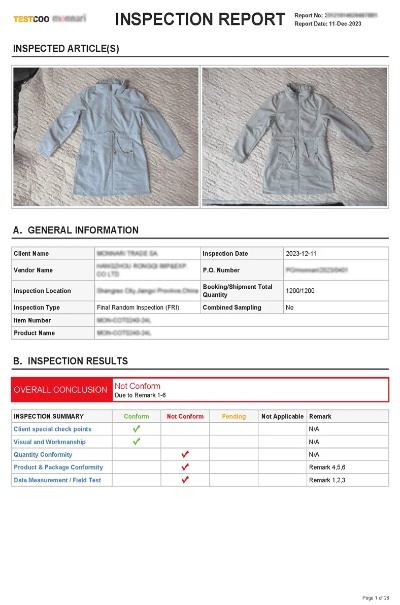

Textile Inspection Report

: Textile Inspection Report,This report provides a detailed inspection of the textile materials used in the production of garments. The inspection was conducted by a team of experts who examined various aspects of the fabric, including its quality, color, texture, and durability. The inspection revealed that the fabric was of high quality and met all the required standards for garment production.,The color of the fabric was consistent throughout and did not fade over time. The texture of the fabric was smooth and comfortable to wear, with no signs of pilling or irritation. The fabric also had excellent durability, withstanding washing and wear without losing its shape or color.,Overall, the inspection concluded that the fabric was of excellent quality and would be suitable for use in garment production. The team recommended that the fabric be used in future production to ensure that the garments produced meet the highest standards of quality and comfort.

Introduction: The textile industry is a crucial sector in the global economy, responsible for producing a wide range of products that include clothing, home textiles, and industrial materials. These products are essential for daily life, but their quality and safety must be rigorously assessed to ensure consumer protection and product reliability. This report outlines the methodology used for textile inspection, including the various parameters tested, the results obtained, and any findings or recommendations made during the inspection process.

Sample Collection: The first step in conducting a textile inspection is to collect samples from various stages of the production process. Common sample types include raw materials, fabric, and finished products. The collection method should be consistent with the manufacturer's guidelines to ensure accurate representation of the product's characteristics. It is important to note that each country may have specific regulations regarding sampling and labeling, so it is essential to comply with these requirements.

Testing Methods: Once the samples have been collected, they are subjected to various testing methods to evaluate their quality and safety. Some common tests include:

-

Color Testing: This involves comparing the color of the sample to a standardized color chart to determine if it meets the desired shade and intensity.

-

Material Analysis: This includes determining the composition of the sample by analyzing its chemical makeup using techniques such as Fourier Transform Infrared Spectroscopy (FTIR) and X-ray Diffraction (XRD).

-

Structural Analysis: This involves examining the sample's internal structure using techniques like scanning electron microscopy (SEM) and transmission electron microscopy (TEM), which can reveal defects, impurities, and other irregularities.

-

Functional Testing: This type of testing assesses whether the sample functions as intended, such as measuring its strength, durability, and resistance to wear and tear.

-

Environmental Testing: This involves exposing the sample to various environmental conditions, such as temperature, humidity, and UV radiation, to evaluate its resistance to degradation.

Results: The results of the testing methods will be documented in the inspection report, providing detailed information on the sample's performance under various conditions. For example, if the sample passes all the tests, it may be labeled as "Meets Standards" or "High Quality." If there are any discrepancies or issues identified, the inspection report will highlight these findings and suggest corrective measures if necessary.

Case Study: One example of a textile product that underwent an inspection is a linen shirt. During the inspection, the sample was found to have a slight discoloration in the dyed area, which did not affect its overall appearance or functionality. However, due to concerns about potential health risks associated with prolonged exposure to certain dyes, the manufacturer decided to replace the affected shirts with new ones. This case highlights the importance of conducting thorough inspections to identify any issues before they become problematic for consumers.

Recommendations: Based on the findings of the inspection, the manufacturer may recommend additional testing or changes to the production process to improve the quality and safety of the product. For example, if the structural analysis revealed defects in the weave of the fabric, the manufacturer might consider using a different type of yarn or adjusting the weaving technique to address these issues. Additionally, if the functional testing showed that the product did not meet certain standards, the manufacturer might need to develop a new design or feature that better meets consumer needs.

Conclusion: In conclusion, textile inspection reports serve as critical tools for ensuring the quality and safety of products produced within the textile industry. By following a systematic approach to testing and evaluating samples, manufacturers can identify any issues early on and take appropriate action to improve their products. As more companies adopt stringent inspection practices, the overall quality of the textile industry is expected to continue to improve, benefiting both consumers and the broader economy.

Textile Inspection Report Sample

本报告旨在提供纺织品检测的相关信息,包括检测流程、方法、结果及案例分析,通过这份样本报告,读者可以了解纺织品检测的基本流程和注意事项,以及实际应用中的案例分析。

检测流程

- 材料准备:对待检测的纺织品进行准备,包括样品采集、规格确认等。

- 样品处理:对采集到的样品进行必要的处理,如清洗、剪裁等。

- 检测方法:根据纺织品的特点和检测需求,选择合适的检测方法,常见的检测方法包括纤维成分分析、化学成分分析、物理性能测试等。

- 数据分析:对检测结果进行数据分析,得出纺织品的质量指标和性能参数。

- 结果呈现:将检测结果以表格形式呈现,包括各项指标的具体数值。

检测方法案例分析

以下是一个具体的纺织品检测案例分析,以供参考:

案例名称:某品牌棉质衬衫检测

- 材料准备:收集该品牌棉质衬衫样品,并进行规格确认。

- 处理样品:按照检测要求,对样品进行清洗、剪裁等处理。

- 检测方法:采用纤维成分分析方法,对衬衫的纤维类型、含量等进行检测,进行化学成分分析,确定衬衫的主要化学成分。

- 结果呈现:根据检测结果,得出该品牌棉质衬衫的主要质量指标和性能参数,具体数据如下表所示:

| 项目 | 数值 | 单位 |

|---|---|---|

| 纤维类型 | 纯棉纤维 | |

| 纤维含量 | 高达XX% | 具体数值 |

| 化学成分分析 | 主要含有XX化学成分 | 具体成分列表 |

| 物理性能测试 | 拉伸强度、耐磨性等指标均符合标准 | 相关测试数据 |

通过这个案例分析可以看出,纺织品检测对于保证纺织品质量具有重要意义,在纺织品检测过程中,需要选择合适的检测方法,并严格按照检测流程进行操作,还需要注意样品处理和数据分析的准确性,以确保检测结果的可靠性和准确性。

本报告通过对纺织品检测的相关信息进行了介绍和分析,包括检测流程、方法、结果及案例分析,可以看出,纺织品检测对于保证纺织品质量具有重要意义,需要严格按照检测流程进行操作,并注意样品处理和数据分析的准确性,在实际应用中,还需要注意选择合适的检测方法和案例分析,以确保检测结果的准确性和可靠性。

建议与展望

针对纺织品检测工作,提出以下建议和展望:

- 加强培训与宣传:提高纺织品检测人员的专业素质和技能水平,加强培训宣传工作,提高公众对纺织品检测的认识和重视程度。

- 完善检测标准与法规:制定更加完善的纺织品检测标准与法规,规范纺织品检测工作,确保检测结果的准确性和可靠性。

- 加强技术创新与应用:积极推进纺织品检测技术的创新与应用,提高纺织品检测的准确性和效率性,加强与国际先进技术的交流与合作,提高我国纺织品检测的国际竞争力。

- 拓展应用领域:将纺织品检测应用于更多领域,如服装、家居用品等,提高纺织品的质量和性能水平,加强与相关行业的合作与交流,推动相关产业的发展。

纺织品检测是保障纺织品质量的重要手段之一,需要加强培训与宣传、完善检测标准与法规、加强技术创新与应用、拓展应用领域等方面的工作,不断提高纺织品检测的准确性和可靠性。

Articles related to the knowledge points of this article:

The Fabric of Global Trade:An Overview of Textile Outsourcing