A Comprehensive Guide to Textile Antimicrobial and Sterilization Equipment

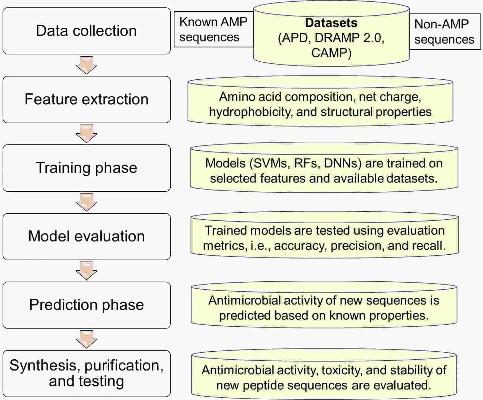

: A Comprehensive Guide to Textile Antimicrobial and Sterilization Equipment,Abstract:,This comprehensive guide aims to provide a thorough understanding of textile antimicrobial and sterilization equipment, including the selection criteria, application methods, and effectiveness evaluation. The guide covers various types of antimicrobial agents used in textiles, such as physical barriers, chemical treatments, and biological agents, and their respective mechanisms of action. Additionally, it discusses the importance of proper equipment selection for effective sterilization processes, including steam sterilizers, UV sterilizers, and autoclaves. Furthermore, the guide emphasizes the need for regular maintenance and inspection of these equipment to ensure their reliability and effectiveness. Finally, it provides practical tips for selecting appropriate antimicrobial agents and sterilization equipment based on specific requirements, including factors such as fabric type, material composition, and intended use. Overall, this guide aims to assist textile professionals in selecting the most suitable antimicrobial and sterilization equipment for their specific applications.

Introduction: In today's world, textiles are an integral part of our daily lives. They come in various forms such as clothing, bedding, and furnishings. However, the constant exposure to germs and bacteria can lead to infections and health problems. That's where textile antimicrobial and sterilization equipment comes into play. In this guide, we will explore the different types of equipment available for textiles and how they work to protect against microbial growth. We will also provide some examples of successful applications and highlight the importance of choosing the right equipment for your specific needs.

Types of Textile Antimicrobial and Sterilization Equipment:

-

Chemical Disinfectants: These are liquid or powdered chemicals that kill or inhibit the growth of microorganisms on textiles. Examples include quaternary ammonium compounds, alcohols, and aldehydes. Chemical disinfectants are effective at killing bacteria and viruses but may not be suitable for all fabrics. For example, they may damage certain synthetic materials or cause color fading.

-

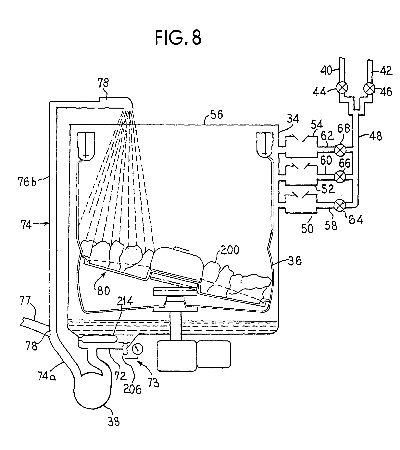

Heat Sterilizers: These use high temperatures to kill or inactivate microorganisms. Examples include steam sterilizers, microwave sterilizers, and autoclave machines. Heat sterilizers are widely used in healthcare settings and require careful handling to avoid damage to fabrics.

-

UV Sterilizers: These use ultraviolet light to kill microorganisms. Examples include UV lamps and UV-sterilized products. UV sterilizers are effective at killing bacteria and viruses but may not be suitable for all fabrics. For example, they may damage certain dyes or cause color fading.

-

Ionizing Radiation Sterilizers: These use high-energy radiation to kill microorganisms. Examples include X-ray sterilizers and electron beam sterilizers. Ionizing radiation sterilizers are effective at killing bacteria and viruses but may not be suitable for all fabrics. For example, they may damage certain dyes or cause color fading.

-

Laminar Airflow Sterilizers: These use a controlled environment with low airflow to kill microorganisms. Examples include laminar airflow cabinets and laminar airflow sterilizers. Laminar airflow sterilizers are effective at killing bacteria and viruses but may not be suitable for all fabrics. For example, they may damage certain dyes or cause color fading.

Examples of Successful Applications:

-

Medical Equipment: Medical devices such as surgical gowns, masks, and gloves are often sterilized using chemical disinfectants or heat sterilizers to prevent cross-contamination during surgeries.

-

Hospital Bedding: Hospital beds and linens are often washed using hot water and detergent to remove any residual bacteria from previous patients. After washing, they are then sterilized using chemical disinfectants or heat sterilizers to ensure cleanliness.

-

Sports Equipment: Sports equipment such as helmets, pads, and balls are often disinfected using chemical disinfectants or heat sterilizers to prevent the spread of germs during games.

-

Home Appliances: Home appliances such as dishwashers, washing machines, and dryers are often cleaned using detergent and hot water to remove any residual bacteria from previous uses. After cleaning, they are then sterilized using chemical disinfectants or heat sterilizers to ensure cleanliness.

Importance of Selecting the Right Equipment:

When selecting textile antimicrobial and sterilization equipment, it is important to consider several factors including the type of fabric being used, the level of sterilization required, and the budget available. For example, chemical disinfectants may be more effective at killing bacteria and viruses but may damage certain fabrics. Heat sterilizers are widely used in healthcare settings but may not be suitable for all fabrics. UV sterilizers are effective at killing bacteria and viruses but may not be suitable for all fabrics. Ionizing radiation sterilizers are effective at killing bacteria and viruses but may not be suitable for all fabrics. Laminar airflow sterilizers are effective at killing bacteria and viruses but may not be suitable for all fabrics. Therefore, it is important to research different options and consult with experts before making a decision.

随着人们对健康和生活品质的追求不断提高,纺织品作为日常生活中的必需品,其抗菌抑菌性能显得尤为重要,为了满足这一需求,纺织品抗菌抑菌设备应运而生,本文将详细介绍这种设备的特点、应用场景以及相关案例。

纺织品抗菌抑菌设备概述

设备类型与功能

纺织品抗菌抑菌设备是一种高效、便捷的纺织品处理设备,主要用于对纺织品进行抗菌抑菌处理,该设备采用先进的抗菌材料和技术,能够有效杀灭细菌、病毒等微生物,防止纺织品受到二次污染。

设备特点

(1)高效杀菌:采用高效杀菌技术,能够快速、有效地杀灭纺织品上的细菌和病毒。

(2)环保节能:设备采用环保材料制造,同时具备节能特点,降低能源消耗和运行成本。

(3)便捷操作:设备操作简便,易于使用和维护。

纺织品抗菌抑菌设备的应用场景

家居用品领域

在家居用品领域,纺织品抗菌抑菌设备主要用于清洁和消毒床上用品、毛巾、衣物等,通过使用该设备,可以有效防止细菌和病毒传播,提高家居环境的卫生和健康水平。

医疗领域

在医疗领域,纺织品抗菌抑菌设备主要用于医疗用品的消毒和灭菌,医院手术衣、口罩、手套等医疗用品,都需要经过严格的消毒和灭菌处理,以确保医疗用品的安全性和有效性。

案例分析

某品牌纺织品抗菌抑菌设备的生产与应用

某品牌纺织品抗菌抑菌设备采用了先进的杀菌技术和环保材料制造,能够有效杀灭纺织品上的细菌和病毒,该设备广泛应用于家居用品领域和医疗领域,为消费者提供了更加健康、安全的纺织品产品。

某地区纺织品抗菌抑菌设备的成功案例

在某地区,某商家通过使用该地区纺织品抗菌抑菌设备,成功解决了当地居民对纺织品污染问题的担忧,该设备不仅提高了居民的生活质量,还为当地经济发展做出了积极贡献。

纺织品抗菌抑菌设备的操作与维护

设备操作步骤

(1)清洗设备:将设备进行清洗,去除表面的污垢和杂质。

(2)消毒处理:将需要处理的纺织品放入设备中,进行高温或紫外线消毒处理。

(3)使用:根据需要处理的纺织品类型和数量,选择合适的处理模式和参数。

设备维护保养

(1)定期检查:定期对设备进行维护保养,确保设备的正常运行。

(2)清洁:定期对设备进行清洁,去除设备表面的污垢和杂质。

纺织品抗菌抑菌设备是一种高效、便捷的纺织品处理设备,能够有效杀灭纺织品上的细菌和病毒,提高纺织品的安全性和卫生性,在家庭用品领域和医疗领域都有广泛的应用前景,该设备的操作与维护也需要注意细节和规范,以确保设备的正常运行和使用效果。

Articles related to the knowledge points of this article:

Understanding and Applying Textile Color Standards

The Art of Textile Treasures:The Story of 珍之韵纺织品