The Environmental Impacts of Textile Pretreatment Processes

The environmental impacts of textile pretreatment processes have been extensively studied. These processes are essential for the production of textile products, but they also have significant negative effects on the environment. The use of chemicals in these processes can lead to water pollution, air pollution, and soil contamination. Additionally, the disposal of wastewater from these processes can pose a threat to aquatic ecosystems. Therefore, it is important to develop sustainable alternatives to reduce the environmental impact of textile pretreatment processes. This can be achieved by using renewable resources such as solar energy and wind energy to power the processes, reducing the use of chemical solvents, and implementing effective waste management practices. By adopting these measures, we can minimize the negative impacts of textile pretreatment processes on the environment and promote sustainable development.

Introduction: Textile production is a crucial industry that contributes significantly to the global economy. However, this sector is also known for its environmental impacts, particularly in terms of waste generation and pollution. Textile pretreatment processes play a significant role in the overall textile production process, and their environmental impacts cannot be overlooked. This paper aims to explore the environmental impacts of textile pretreatment processes and propose ways to reduce these impacts.

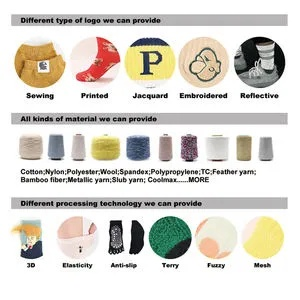

Textile Pretreatment Overview: Textile pretreatment refers to the steps taken before the actual dyeing or finishing process. These steps include cleaning, scouring, bleaching, and degreasing. Each of these steps has its own set of environmental concerns.

Cleaning: The cleaning step involves removing any dirt or impurities from the fabric. This can be done through mechanical cleaning or chemical cleaning. Mechanical cleaning uses brushes or rollers to remove dirt, while chemical cleaning uses detergents to break down dirt and grease. Both methods have their environmental impacts. Mechanical cleaning generates large amounts of wastewater, which can contain toxic chemicals such as detergents and soaps. Chemical cleaning, on the other hand, releases harmful chemicals into the environment, including chlorine and heavy metals.

Scouring: Scouring is another important step in textile pretreatment. It involves scrubbing the fabric with abrasive materials to remove any remaining dirt or stains. This process generates a significant amount of wastewater, which can contain toxic chemicals such as detergents and soaps. Additionally, abrasive materials can damage the fabric during the process, leading to increased waste generation.

Bleaching: Bleaching is the final step in textile pretreatment. It involves using chemicals to remove any color from the fabric. This process generates a significant amount of wastewater, which can contain toxic chemicals such as chlorine and heavy metals. The use of bleaching agents can also harm aquatic life and disrupt ecosystems.

Degreasing: Degreasing is the last step in textile pretreatment. It involves removing any remaining grease or oil from the fabric. This process generates a significant amount of wastewater, which can contain toxic chemicals such as detergents and soaps. Additionally, degreasing agents can harm aquatic life and disrupt ecosystems.

Environmental Impacts: The textile pretreatment process has a significant impact on the environment. The waste generated during these processes can cause water pollution, soil contamination, and air pollution. Chemicals used in these processes can also harm aquatic life and disrupt ecosystems.

Case Study: One example of the environmental impacts of textile pretreatment is the case of a textile company in India. The company was producing high-quality cotton fabrics using traditional methods, but it was facing increasing environmental regulations due to the negative impacts of its pretreatment processes. The company decided to switch to more eco-friendly methods, such as using natural detergents and reducing waste generation. As a result, the company's environmental impacts decreased significantly, and it became one of the most sustainable textile companies in the industry.

Conclusion: In conclusion, textile pretreatment processes have significant environmental impacts. The use of chemicals, waste generation, and pollution are some of the key issues associated with these processes. To address these issues, it is essential to adopt more eco-friendly methods and practices in textile production. By doing so, we can minimize our environmental footprint and contribute to a sustainable future for our planet.

Articles related to the knowledge points of this article:

Exploring the Wonderland of Disney Home Textiles

Preventing Textile Dyeing Issues with Strategies and Case Studies