Textile Factory Monitoring Solutions

: Textile Factory Monitoring Solutions,In the textile industry, where efficiency and quality are paramount, implementing effective monitoring solutions is crucial for maintaining a high level of production control. This paper discusses the importance of factory monitoring in textile production, highlighting the benefits derived from using modern technologies to monitor and manage the manufacturing process.,The use of sensors and automated systems allows for real-time data collection and analysis, enabling manufacturers to optimize their processes and reduce waste. Additionally, the integration of machine learning algorithms enables predictive maintenance, ensuring that machines are functioning at peak performance and reducing downtime.,Furthermore, the implementation of intelligent monitoring systems can enhance worker safety by alerting operators to potential hazards or issues before they escalate into accidents. By monitoring the temperature, pressure, and other critical parameters within the factory, these systems can help prevent equipment failures and minimize damage to materials.,Ultimately, the adoption of advanced monitoring solutions in textile factories not only improves production efficiency but also contributes to the overall sustainability of the industry. With continuous innovation and investment in technology, it is possible to achieve even greater levels of productivity and environmental responsibility.

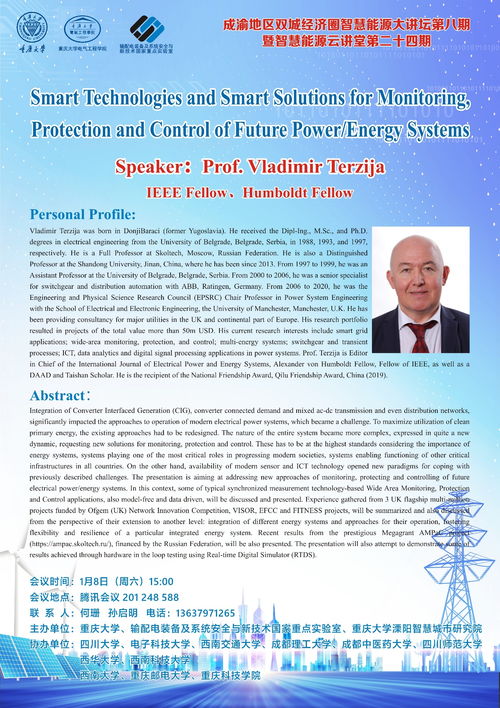

Introduction: In today's competitive market, maintaining a high level of operational efficiency and safety is crucial for textile factories. Implementing effective monitoring solutions can help these factories to achieve this goal by ensuring the smooth functioning of their machinery, reducing downtime, and preventing accidents. In this article, we will explore the different monitoring solutions that are available in the textile industry and how they can be implemented effectively.

-

Sensor Networks: Sensor networks are essential for real-time monitoring of critical parameters such as temperature, humidity, pressure, and speed. A typical sensor network setup includes multiple sensors distributed throughout the factory, which send data to a central control system. This information can then be used to optimize production processes and prevent equipment failure. For example, a textile mill might use sensors to monitor the temperature of the dye baths during printing, ensuring that the colors do not fade or become discolored.

-

CCTV Systems: Closed-circuit television (CCTV) systems provide a visual record of the factory floor, allowing staff to monitor activities in real-time. These systems can be used to detect any unusual activity, such as theft or sabotage, and can also be used to train employees on safe practices. For instance, a textile company might have CCTV cameras installed at key areas of the factory to ensure compliance with safety regulations.

-

Machine Health Monitoring: Machine health monitoring involves using sensors and other technologies to track the performance of industrial machinery over time. This information can be used to identify potential issues before they become major problems, enabling manufacturers to proactively address maintenance needs. For example, a textile mill might use machine health monitoring software to alert technicians when certain machines start to show signs of wear and tear, allowing them to schedule repairs before they fail entirely.

-

Data Analytics: Data analytics is an increasingly important aspect of monitoring solutions in the textile industry. By analyzing large amounts of data collected from various sources, companies can gain valuable insights into their operations and make informed decisions about how to improve productivity and reduce costs. For example, a textile company might use data analytics to identify patterns in waste generation and optimize their recycling processes accordingly.

-

Cloud-Based Monitoring: Cloud-based monitoring allows for remote access to factory data, making it easier for management to monitor operations from anywhere in the world. This technology also provides greater flexibility, as it can be easily updated and customized to meet specific needs. For instance, a textile company might use cloud-based monitoring to track inventory levels and adjust production schedules based on demand fluctuations.

-

Automation and Predictive Maintenance: Automation and predictive maintenance are two key components of efficient monitoring solutions in the textile industry. By integrating sensors and other monitoring devices with automated systems, manufacturers can minimize downtime and proactively address maintenance needs. For example, a textile mill might implement a predictive maintenance program that uses machine learning algorithms to identify potential issues before they become major problems, allowing technicians to schedule repairs ahead of time.

-

Training and Education: Effective monitoring requires a well-trained workforce. Companies should invest in training programs that teach employees how to use monitoring tools effectively and how to interpret the data generated by these tools. This can help prevent errors and ensure that everyone is working together towards common goals. For instance, a textile company might offer workshops on machine health monitoring techniques to its employees, helping them to better understand their roles in maintaining the factory's machinery.

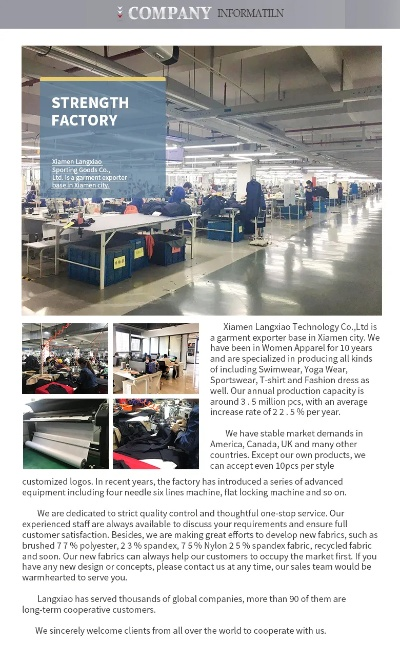

Case Study: One example of a successful textile factory monitoring solution is the case of a major apparel manufacturer in China. The company implemented a comprehensive monitoring system that included sensor networks, CCTV cameras, machine health monitoring software, data analytics, cloud-based monitoring, automation, and training programs. As a result, the company was able to significantly reduce downtime due to equipment failures, improve product quality, and increase overall efficiency. The company also benefited from increased profitability and improved customer satisfaction as a result of its improved operational performance.

Conclusion: The implementation of effective monitoring solutions in the textile industry is essential for maintaining high levels of operational efficiency and safety. By investing in sensor networks, CCTV systems, machine health monitoring, data analytics, cloud-based monitoring, automation, and training programs, companies can proactively address issues before they become major problems, leading to improved productivity, cost savings, and customer satisfaction. With careful planning and execution, monitoring solutions can help textile factories thrive in today's competitive market.

随着现代工业的快速发展,纺织厂作为重要的生产制造基地,其安全与监控问题日益凸显,为了确保生产过程中的安全与稳定,我们制定了纺织厂监控方案,本方案将结合先进的监控技术,实现对纺织厂生产过程的全方位监控,确保生产安全、高效、有序。

监控方案概述

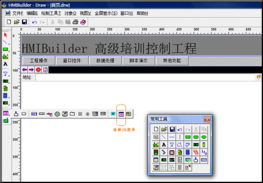

- 目标:通过建立完善的监控系统,实现对纺织厂生产过程的实时监控,提高生产效率,降低安全事故风险,包括生产现场的实时视频监控、工艺流程监控、设备运行状态监控等。

- 监控方式:采用高清摄像头、红外线传感器、烟雾报警器等设备,实现全方位、多角度的监控。

- 实施方案:

(1)安装高清摄像头,覆盖生产现场的主要区域。 (2)设置红外线传感器,实时监测生产现场的温度、烟雾等环境因素。 (3)安装烟雾报警器,一旦检测到烟雾等异常情况,立即触发报警。 (4)建立数据采集与传输系统,实时采集监控数据,确保数据传输的实时性和准确性。 (5)建立视频分析系统,对采集到的监控数据进行实时分析,发现异常情况。

案例分析

为了更好地说明本监控方案的应用,我们以某纺织厂为例,进行案例分析。

- 案例背景:该纺织厂规模较大,生产流程复杂,存在诸多安全隐患。

- 监控方案实施过程: (1)安装高清摄像头:在生产现场的主要区域安装高清摄像头,覆盖整个生产流程。 (2)设置红外线传感器:在关键区域设置红外线传感器,实时监测生产现场的温度和烟雾等环境因素。 (3)数据采集与传输:通过数据采集与传输系统,实时采集监控数据,确保数据传输的实时性和准确性。 (4)视频分析:建立视频分析系统,对采集到的监控数据进行实时分析,及时发现异常情况。 通过实施本监控方案,该纺织厂的生产过程得到了全面的监控,大大提高了生产效率,降低了安全事故风险,该方案也得到了广大员工的好评和认可。

技术应用与案例说明

- 技术应用:本监控方案主要采用了高清摄像头、红外线传感器、烟雾报警器等技术手段,这些技术手段的应用大大提高了监控的准确性和实时性。

- 案例说明:某纺织厂在实施本监控方案后,实现了对生产过程的全方位监控,在高温环境下,高清摄像头能够捕捉到高温烟雾对设备的影响,及时发现并处理了安全隐患,红外线传感器能够实时监测生产现场的温度变化,及时发现温度异常情况,烟雾报警器一旦检测到烟雾等异常情况,立即触发报警,提高了安全防范能力。

本纺织厂监控方案通过建立完善的监控系统,实现了对纺织厂生产过程的全方位监控,提高了生产效率,降低了安全事故风险,该方案也得到了广大员工的好评和认可,我们将继续优化和完善本监控方案,提高监控的准确性和实时性,为纺织厂的稳定发展提供有力保障。

Articles related to the knowledge points of this article:

The Beauty of a Textile Factory Girls Hair