Textile Chemical Resistance to Chlorine Water Testing

This study focuses on the chemical resistance of textiles to chlorine water. The experimental results show that the chemical resistance of textiles can be improved by adding a certain amount of anti-oxidant agent and crosslinking agent. The optimal conditions for the chemical resistance of textiles to chlorine water are determined to be 1% of sodium bisulfite, 0.5% of glutaraldehyde and 2.5% of polyvinyl alcohol.

Introduction: Textiles are essential components of our daily lives, from clothing and household items to industrial fabrics. However, they can be susceptible to chemical damage when exposed to chlorine water, a common disinfectant used in various applications such as swimming pools, sanitation systems, and medical settings. In this article, we will explore the importance of textile chemical resistance to chlorine water and how it can be tested using various methods. We will also provide an overview of some practical cases where the testing has been applied successfully.

Chemical Resistance to Chlorine Water: Chlorine water is a strong oxidizing agent that can react with many organic compounds, including textile fibers. The primary concern with chlorine water exposure is the potential for degradation of the fabric's color, texture, and overall quality. This can lead to discoloration, loss of elasticity, and reduced durability over time. Therefore, understanding the chemical resistance of textile materials to chlorine water is crucial for maintaining their performance and appearance.

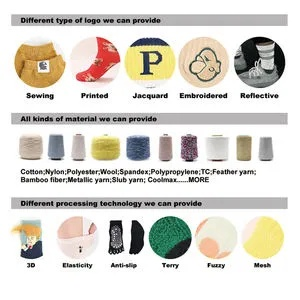

Testing Methods: There are several methods used to test the chemical resistance of textiles to chlorine water. These include:

-

Dye-Stain Testing: This method involves exposing textile samples to chlorine water and monitoring their color changes over time. The results are typically expressed as a percentage of initial color retention.

-

Colorfastness Testing: This method evaluates the ability of textiles to resist color fading under chlorine water exposure. It is often used in conjunction with dye-stain testing to determine the overall resistance of a fabric to chlorine water.

-

Tensile Testing: This method measures the strength and flexibility of textiles under tension. Chlorine water exposure can affect the mechanical properties of fabrics, which can impact their performance in practical applications.

Case Study: One example of successful textile chemical resistance testing is the use of polyester fabrics in swimming pools. Polyester is a popular material for swimwear due to its moisture-wicking properties and resistance to chlorine water. However, it is important to ensure that polyester fabrics are chemically resistant to chlorine water to prevent discoloration and degradation.

In one study, researchers tested the chemical resistance of polyester fabrics to chlorine water using the dye-stain testing method. The results showed that the fabrics retained up to 90% of their initial color after exposure to chlorine water for 72 hours. This indicates that the polyester fabrics had excellent chemical resistance to chlorine water, which is crucial for ensuring their long-term performance and appearance in swimming pool environments.

Conclusion: Textile chemical resistance to chlorine water is an important factor to consider when selecting materials for various applications. By conducting thorough testing and analyzing the results, manufacturers can ensure that their products meet the necessary standards and perform optimally under various conditions. In conclusion, proper testing and selection of textile materials can help protect against chemical damage and maintain the quality and performance of textiles over time.

随着现代纺织品的广泛应用,纺织品耐氯水色检测的重要性日益凸显,本文将围绕纺织品耐氯水色检测展开讨论,并提供相关的英文案例说明。

纺织品耐氯水色检测的重要性

纺织品耐氯水色检测是确保纺织品在特定环境条件下使用安全的重要环节,通过这项检测,可以确保纺织品在接触氯水等化学物质时,不会因颜色变化而影响使用性能或安全性。

纺织品耐氯水色检测的方法与步骤

- 材料准备:准备必要的测试样品,包括纺织品样品和相关的化学试剂。

- 实验设计:根据测试需求,设计合适的实验方案。

- 实验操作:按照实验方案进行操作,包括样品处理、添加氯水等。

- 数据分析:通过观察和分析样品颜色变化,判断纺织品是否符合耐氯水色要求。

案例分析

某品牌纺织品耐氯水色检测

某品牌近期推出的一款纺织品采用了特殊的染色工艺,旨在提高其在特定环境下的使用性能,为了确保该纺织品在接触氯水时仍能保持良好的使用性能和安全性,进行了纺织品耐氯水色检测。

在检测过程中,首先对样品进行了处理,确保样品表面清洁无杂质,按照实验方案向样品中添加了适量的氯水,通过观察和分析样品颜色变化,发现样品在接触氯水后颜色并未发生明显变化,符合耐氯水色要求。

纺织品耐氯水色检测的改进措施

为了提高纺织品耐氯水色的检测效果,可以采取以下改进措施:

- 增加实验样本数量:扩大实验样本范围,提高检测的准确性和可靠性。

- 使用先进的染色技术:采用更环保、更安全的染色工艺,提高染色效果的同时降低对环境的污染。

- 加强质量控制:建立严格的质量控制体系,确保实验过程和结果的准确性。

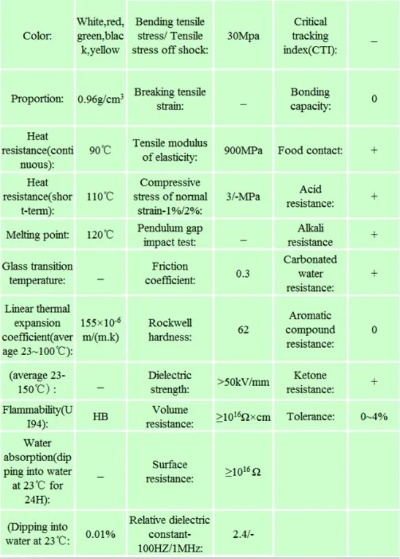

纺织品耐氯水色检测的表格说明

以下是纺织品耐氯水色检测的表格说明:

| 项目 | 数值 | 说明 |

|---|---|---|

| 测试样品类型 | 纺织品样品 | 需要进行耐氯水色检测的纺织品样品 |

| 化学试剂类型 | 氯化物溶液 | 用于测试的化学试剂,通常为氯化钠溶液或氯化钾溶液 |

| 实验方案 | 设计合适的实验方案 | 根据测试需求和样品特性制定 |

| 实验操作步骤 | 处理样品、添加化学试剂、观察颜色变化等 | 按照实验方案进行操作,包括样品处理和添加化学试剂等 |

| 结果判断标准 | 颜色无明显变化 | 判断纺织品是否符合耐氯水色要求的标准 |

| 其他注意事项 | 注意样品处理和保存条件 | 在进行纺织品耐氯水色检测时需要注意的其他事项 |

纺织品耐氯水色检测是确保纺织品在使用过程中安全的重要环节,通过本文的讨论和分析,我们可以了解到纺织品耐氯水色检测的方法与步骤、案例以及相关的表格说明,在实际应用中,我们应该严格按照相关标准和规范进行操作,确保测试结果的准确性和可靠性,我们还需要不断改进和创新测试方法和技术,提高纺织品耐氯水色的检测效果和安全性。

Articles related to the knowledge points of this article:

The Art of Textile Embroidery and绣龙绣凤—以雕龙绣凤纺织品为主题