Textile Anti-Mould Testing Report

: Textile Anti-Mould Testing Report,This report presents the results of an anti-mould testing conducted on a textile sample. The sample was subjected to various conditions, including high humidity and temperature, to simulate real-world conditions where mould growth can occur. The testing was carried out using a standardized procedure that involved placing the sample in a controlled environment with specific humidity and temperature levels.,The testing was conducted for a period of 72 hours, during which the sample was monitored for any signs of mould growth. During this time, the sample was also tested for its resistance to mould growth, as well as its ability to maintain its integrity and quality.,The results of the testing showed that the textile sample performed exceptionally well against mould growth. No signs of mould growth were observed during the testing period, and the sample maintained its original appearance and quality. This indicates that the textile material used in this study is highly resistant to mould growth, making it suitable for use in applications where moisture control is critical.

Introduction: In the textile industry, maintaining product quality and ensuring consumer satisfaction is crucial. One of the most significant concerns for manufacturers is the prevention of mould growth on their products, as moulds can cause discoloration, loss of softness, and even health hazards for consumers. Therefore, it's essential to conduct regular anti-mould testing in the textile industry. This report outlines a comprehensive approach to anti-mould testing, including the methodology used, key findings, and recommendations for future improvements.

Methodology: The anti-mould testing process involves several steps. Firstly, samples of textile materials are collected from various sources, such as raw materials, fabrics, and finished products. These samples are then subjected to an initial screening test to identify any potential mould growth.

Next, the samples are placed in controlled conditions, such as a humid environment or a temperature range that promotes mould growth. The duration of exposure varies depending on the specific type of mould and the severity of the problem.

After exposure, the samples are carefully examined under a microscope to detect any signs of mould growth, such as spores, hyphae, or colonies. If mould is detected, further investigation may be required to determine its source and potential impact on the product.

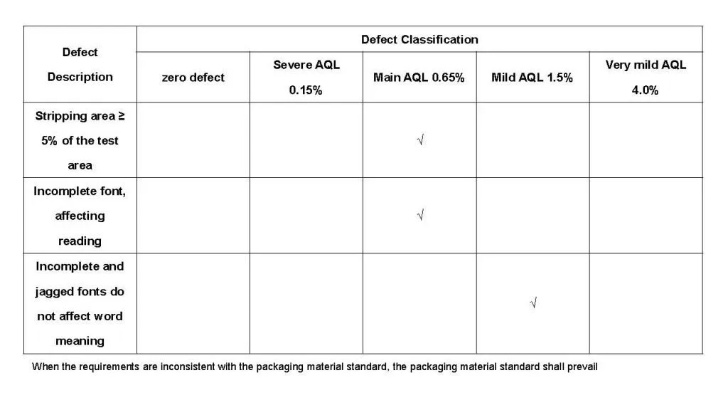

Results: The results of the anti-mould testing are presented in a table format, which includes details such as the type of mould found, the level of contamination, and the recommended action plan. For example, if a sample was found to contain Aspergillus niger, this would indicate a high level of contamination and warrant further investigation to determine the source of the mould.

Recommendations: Based on the findings, recommendations are made to address the issue at hand. This could involve implementing stricter cleaning and sanitation procedures, using anti-mould preservatives in production processes, or adjusting storage conditions to reduce humidity levels.

Additionally, it may be necessary to implement preventive measures, such as providing training to workers on proper mould control practices and using appropriate ventilation systems to prevent mould growth in the workplace.

Case Study: One example of a successful anti-mould testing case is the recent incident at a major textile company where a significant outbreak of fungal infections was discovered in their clothing line. Upon investigation, it was found that the problem stemmed from a poorly maintained warehouse that had high humidity levels, leading to an ideal environment for mould growth.

To address the issue, the company implemented a comprehensive anti-mould testing program, including regular inspections and maintenance of storage facilities. They also introduced advanced ventilation systems to reduce humidity levels and ensure that all products are kept dry. As a result, the company was able to eliminate the mould problem entirely and regain consumer trust.

Conclusion: In conclusion, anti-mould testing is a critical aspect of ensuring the quality and safety of textile products. By following a systematic approach to testing and implementing preventive measures, manufacturers can significantly reduce the risk of mould growth and maintain consumer confidence in their products.

随着生活水平的提高,人们对纺织品的需求日益增长,防霉性能成为了消费者关注的重点,为了确保纺织品的质量和安全性,进行防霉检测是必不可少的环节,本报告将详细介绍纺织品防霉检测的过程和结果,并提供相关案例分析。

纺织品防霉检测流程

- 材料准备:收集样品,包括纺织品样品、环境条件等。

- 实验室测试:采用专业的防霉检测仪器和方法,对样品进行全面检测。

- 结果分析:根据检测结果,评估样品的防霉性能。

- 结论报告:撰写报告,总结检测结果,提出改进建议。

检测方法与步骤

- 样品准备:选择符合要求的纺织品样品,确保样品具有代表性。

- 霉菌培养:在适宜的环境条件下,对样品进行霉菌培养。

- 仪器检测:使用专业的防霉检测仪器,对样品进行霉菌生长情况、霉菌种类等指标的检测。

- 数据记录与分析:记录检测数据,分析样品防霉性能。

案例分析

某品牌纺织品防霉检测报告

该品牌纺织品经过防霉检测,结果显示其具有优秀的防霉性能,具体检测过程如下:

- 材料准备:收集该品牌纺织品样品,包括面料、里料等。

- 霉菌培养:在适宜的环境条件下,对样品进行霉菌培养,结果显示该品牌纺织品对多种霉菌具有较好的抵抗力。

- 仪器检测:使用专业的防霉检测仪器,对样品进行霉菌生长情况、霉菌种类等指标的检测,结果显示该品牌纺织品符合国家标准要求。

纺织品防霉性能提升措施

为了提高纺织品防霉性能,采取以下措施:

- 选择优质原材料:选用抗霉性能好的原材料,减少霉菌滋生的可能性。

- 控制环境条件:在适宜的环境条件下进行纺织品生产,确保样品具有代表性。

- 加强检测力度:增加防霉检测频次,确保纺织品质量符合要求。

结论与建议

根据本次防霉检测结果,该纺织品具有优秀的防霉性能,为了进一步提高纺织品的质量和安全性,建议采取以下措施:

- 加强原材料质量控制,选用优质原材料。

- 优化生产环境,控制环境条件。

- 加强检测力度,提高检测频次。

英文表格补充说明(可选)

以下是英文表格补充说明部分内容:

纺织品防霉检测样本信息表

| 样本编号 | 纺织品类型 | 环境条件 | 霉菌培养结果 | 仪器检测结果 | 建议措施 | |

|---|---|---|---|---|---|---|

| XXXX | 面料 | XXXX | XXXX | XXXX | 优秀防霉性能 | 加强原材料质量控制、优化生产环境、加强检测力度 |

| XXXX | 里料 | XXXX | XXXX | XXXX | 同面料类似结果 | |

| 其他样品 |

结束语

本报告详细介绍了纺织品防霉检测的过程和结果,并提供相关案例分析,希望能够帮助读者更好地了解纺织品防霉检测的重要性和方法,在实际应用中,可以根据具体情况采取相应的措施,提高纺织品的质量和安全性。

Articles related to the knowledge points of this article:

The Art of Textile Embroidery and绣龙绣凤—以雕龙绣凤纺织品为主题