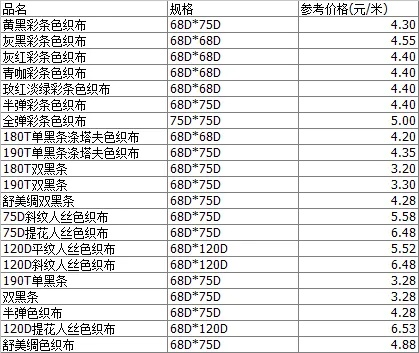

Detailed Analysis of Haian Tide Trend Textiles Processing

Haian Tide Trend Textiles Processing is a complex industrial process that involves the use of advanced technology to manufacture high-quality textile products. The process begins with the collection and preparation of natural fibers, such as cotton, wool, or silk, which are then subjected to various treatments to enhance their properties. These treatments may include bleaching, dyeing, softening, and finishing processes.,Once the fibers have been treated, they are spun into yarn, which is then woven into fabric. The final product is a high-quality textile that can be used in a variety of applications, including clothing, home furnishings, and outdoor gear.,The Haian Tide Trend Textiles Processing industry is highly competitive, with many companies vying for market share. To succeed in this industry, manufacturers must invest in research and development to improve their production processes and create new products that meet the demands of consumers. Additionally, they must focus on sustainability and environmental responsibility to appeal to customers who value these factors.

Introduction: In the realm of textile manufacturing, Hai'an Tide Trend is a name synonymous with quality and innovation. With a focus on sustainability and eco-friendliness, this company has carved out a niche for itself in the global market. In this article, we delve into the details surrounding their textile processing operations, highlighting the key factors that contribute to their success.

Production Process: Hai'an Tide Trend adopts a comprehensive approach to textile processing, ensuring every step of the process aligns with international standards while maintaining its unique identity. The company's production facilities are equipped with state-of-the-art machinery, including high-speed computerized knitting machines, dyeing units, and finishing lines. These advanced tools enable them to produce a wide range of fabrics, from luxurious silk to functional technical materials.

The production process begins with the selection of raw materials, which are sourced from reputable suppliers who adhere to strict environmental and ethical practices. The materials undergo thorough inspections to ensure they meet the company's quality requirements. Once the raw materials are ready, they are processed through a series of steps, each aimed at enhancing their properties and end-use performance.

For instance, during the knitting stage, the yarns are carefully manipulated by skilled operators using specialized knitting machines. The resulting fabrics are then subjected to various treatments, such as dyeing and finishing, where they are enhanced in color, texture, and durability. The finished products are inspected for defects and any irregularities are promptly addressed.

Quality Control: Quality control is a cornerstone of Hai'an Tide Trend's manufacturing process. The company employs a multi-tiered quality assurance system that includes regular audits, sample testing, and third-party certifications. Every batch of fabric is subject to stringent checks, ensuring that it meets the company's high standards for quality and performance.

Moreover, the company maintains close communication with its customers, allowing them to provide feedback on their products. This feedback is used to identify areas for improvement and refine the manufacturing process accordingly. By doing so, Hai'an Tide Trend ensures that its products continue to meet or exceed customer expectations.

Sustainability Practices: At Hai'an Tide Trend, sustainability is not just a buzzword; it is an integral part of their business model. They prioritize reducing waste and minimizing the environmental impact of their operations. For example, the company uses recycled water in their dyeing processes, reducing the need for freshwater sources. Additionally, they implement energy-efficient lighting and HVAC systems, further contributing to their commitment to sustainability.

Furthermore, Hai'an Tide Trend supports local communities by providing jobs and training opportunities within their supply chain. They also donate a portion of their profits to charitable organizations that work towards social and environmental causes. By doing so, they demonstrate their dedication to making a positive impact on society.

Case Study: One example of how Hai'an Tide Trend's sustainable practices have benefitted their customers is their collaboration with fashion brand "Luxury Trend." The brand partnered with Hai'an Tide Trend to create a collection of sustainable clothing inspired by the ocean. Using eco-friendly materials and innovative designs, the collection was designed to raise awareness about marine pollution and promote responsible consumption.

This partnership not only showcased the company's commitment to sustainability but also helped them gain new customers who were attracted to their eco-friendly products. As a result, sales of the collection increased significantly, demonstrating the effectiveness of sustainable marketing strategies.

Conclusion: In conclusion, Hai'an Tide Trend stands out among textile manufacturers due to its commitment to quality, sustainability, and innovation. Their comprehensive production process, coupled with rigorous quality control measures and sustainable practices, sets them apart from competitors. By embracing these principles, Hai'an Tide Trend is positioned to succeed in the ever-evolving world of textile manufacturing.

海安作为纺织业的重要城市,其纺织品加工行业近年来呈现出蓬勃发展的态势,本报告将详细介绍海安潮流纺织品的加工详情,包括工艺流程、设备设施、质量控制等方面,并通过案例分析进一步说明。

工艺流程

原料采集

海安地区广泛收集各类天然纤维原料,包括棉、麻、丝、毛等。

纺织加工

在纺织加工过程中,采用先进的机器设备进行织造、染整等工序,具体工艺包括织造、缝纫、印花、染色等。

质量控制

海安纺织品加工企业注重产品质量控制,采用严格的质量检测标准,确保产品符合国家标准,企业还建立了一套完善的追溯体系,确保产品的来源可追溯。

设备设施

设备种类与数量

海安地区拥有各种类型的纺织加工设备,包括织布机、染整设备、印花设备等,企业还配备了先进的自动化生产线,提高了生产效率。

设备性能与维护情况

设备性能良好,能够满足生产需求,企业定期对设备进行维护和保养,确保设备的稳定性和可靠性,企业还建立了设备维修档案,记录设备的维修历史和故障情况。

案例分析

以某海安潮流纺织品加工企业为例,详细说明其加工流程和质量控制情况。

案例介绍

该企业采用先进的纺织加工技术和设备,专注于潮流纺织品的设计和生产,企业注重产品质量控制,建立了完善的追溯体系和质量检测标准,企业还注重环保和可持续发展,采用环保材料和节能技术。

加工流程

原料采集:该企业从当地农田收集各类天然纤维原料。 织布:采用先进的织布机进行织造,生产出各种款式和颜色的纺织品。 缝纫:采用先进的缝纫设备进行缝制,提高产品的美观度和舒适度。 印花:采用先进的印花设备进行印花处理,提高产品的图案设计和色彩搭配。 染色:采用先进的染色技术对纺织品进行染色处理,提高产品的颜色鲜艳度和耐久性。 质量控制:该企业注重产品质量控制,建立了严格的检测标准和追溯体系,企业还建立了员工培训机制和质量管理体系,确保产品质量符合国家标准。 3. 质量控制案例分析

在该企业的质量控制过程中,采用了多种质量控制方法和技术手段,建立了严格的原料采购和验收制度,确保原料的质量符合国家标准,建立了生产过程的质量控制体系,对每个生产环节进行严格的质量检测和控制,该企业还注重员工培训和技能提升,提高员工的操作技能和质量意识,建立了完善的追溯体系和质量检测标准档案,确保产品的来源可追溯和质量可控制。

海安潮流纺织品加工行业在近年来呈现出蓬勃发展的态势,该行业注重工艺流程、设备设施和质量控制等方面的发展,不断提高产品质量和竞争力,该行业还注重环保和可持续发展,采用环保材料和节能技术,通过案例分析可以看出,该企业在质量控制方面做得非常出色,值得其他企业学习和借鉴。

Articles related to the knowledge points of this article:

The Unique Appeal of the Three Dragon Needle Textile Wholesale Market

The Textile Traceability Platform Revolution

Guide to Completing the Wenzhou Textile Product CE Certification Process