The Multifaceted World of Textile Adhesives

Textile adhesives, an integral part of our daily lives, have evolved from simple bonding agents to sophisticated solutions that cater to the unique requirements of various textile products. These versatile adhesives come in a variety of forms, each with its own set of properties and applications. From hot melt adhesives that adhere to fabrics at high temperatures to cold-setting adhesives that solidify quickly, these materials offer a broad spectrum of solutions to address a wide range of textile issues. As industries continue to push boundaries, the development and optimization of these adhesives are key to ensuring seamless production processes and product performance. The interdisciplinary nature of textile adhesive science also highlights the importance of collaboration between researchers, engineers, and industry professionals to drive innovation and improve the quality of textile products.

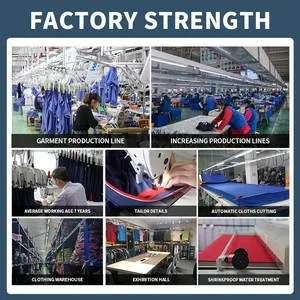

In the world of textiles and garment manufacturing, adhesives play an indispensable role. These versatile substances serve as the glue that binds fabrics together, securing them in place during construction, repair, or even alteration. They are often overlooked but essential components in the production process, offering both practicality and durability to the end product.

Textile adhesives can be classified into several categories based on their function and application. Here's a breakdown with some examples:

-

Sealants: These are used for sealing seams and joints to prevent leakage and maintain structural integrity. Examples include silicone sealants, polyurethane adhesives, and epoxy resin.

-

Hot Glue: A popular DIY option, hot glue is a liquid adhesive typically composed of a mix of water-soluble polymers like polyester or cellulose acetate dissolved in alcohol. It dries quickly and adheres well to most surfaces.

-

Epoxy Resins: Epoxy resins are high strength and durable materials used for bonding heavy-duty applications such as furniture, cabinetry, or sports equipment. They are formulated to cure completely when exposed to heat and UV light.

-

Polyurethane Adhesives: Polyurethane adhesives offer excellent adhesion, flexibility, and resistance to chemicals and solvents. They can be applied by hand or sprayed onto fabrics and then cured with ultraviolet light or heat.

-

Vacuum Sealers: For industrial applications where vacuum sealing is necessary, adhesives are used between layers of fabric to form a sealed pouch. This technique is commonly employed in garment manufacturing.

-

Waterproof Adhesives: In industries dealing with water exposure, waterproof adhesives are essential for maintaining waterproof integrity over time. Examples include silicone and acrylic adhesives.

-

Pressure-Sensitive Tape (PST): PSTs are designed for use under pressure, making them ideal for temporary bonding applications. They release quickly upon unwinding, providing instant bonding without leaving residue.

-

Adhesive Films: These are thin films made of polymeric material that can be applied to various surfaces, including fabrics, to provide permanent bonding or temporary support. Common types include polypropylene (PP), polyethylene (PE), and polyamide (PA).

-

Self-Healing Adhesives: These innovative products have healing capabilities, allowing them to reattach after minor damage occurs. Self-healing properties are particularly useful in the garment industry for restitching small tears.

-

Bio-based Adhesives: With increasing environmental concerns, bio-based adhesives are becoming increasingly popular. Made from renewable resources like cornstarch, these adhesives offer sustainable alternatives to traditional petroleum-based ones.

To give you an idea of how these different adhesives might work in practice, let's take a closer look at an example using polyurethane adhesive.

Imagine a garment manufacturer needing to repair torn denim jeans. Using a heat gun, the manufacturer would apply a small amount of polyurethane adhesive directly onto the tear site. Once the glue has dried, it forms a firm bond between the denim fabrics, effectively mending the jeans and preserving their quality.

Another scenario involves a textile company working with a customer who requires waterproof treatment on all seams of a new collection of swimwear. Using a specialized waterproof adhesive, the manufacturer applies the adhesive to each seam using a specially designed tool. After curing, the adhesive forms a water-resistant barrier that protects the fabric from moisture and contaminants.

The choice of adhesive not only depends on the specific needs of the product but also on the properties of the fabric being worked with. For instance, silk, which is known for its softness and delicate texture, should not be subjected to harsh chemicals or high temperature curing processes; therefore, it may require a specialized adhesive specifically designed for silk.

In conclusion, textile adhesives serve as critical components in the manufacture of clothing and other textile products. From simple repairs to complex structures, these materials ensure that garments remain strong, durable, and aesthetically pleasing. By understanding the different types and applications of adhesives, we can better appreciate their importance in the textile industry.

纺织品黏合剂简介

纺织品黏合剂是一种用于增强或固定纺织品之间的粘合力的化学物质或材料,它们广泛应用于各种领域,如服装、家居装饰、工业生产等,纺织品黏合剂的主要作用是将不同材质的纺织品牢固地粘合在一起,提高产品的质量和性能。

黏合剂种类与特性

-

天然黏合剂:天然黏合剂通常来源于植物提取物或动物胶,具有环保、天然的特性,它们通常具有较高的粘接力,但可能存在某些限制,如不耐高温、易受环境影响等。

-

合成黏合剂:合成黏合剂是一种经过特殊工艺加工的化学物质,具有高强度、高稳定性、耐高温等特性,它们通常具有更好的耐久性和持久性,适用于各种不同的材质和用途。

黏合剂的应用案例

服装行业 在服装行业中,纺织品黏合剂被广泛应用于各种面料之间的粘合,某些品牌的服装使用了特殊的黏合剂,可以将不同材质的面料牢固地粘合在一起,提高服装的耐穿性和舒适度。

家居装饰 在家居装饰中,纺织品黏合剂也被广泛应用,某些家居用品使用了特殊的黏合剂,可以将布料、木材等材质进行粘合,制作出各种美观实用的家居装饰品。

黏合剂的使用方法与注意事项

使用方法:在使用纺织品黏合剂时,需要按照产品说明书上的步骤进行操作,将待粘合的表面清洗干净,确保表面干燥、无油污,将黏合剂涂抹在需要粘合的部位上,可以使用刷子或滚筒进行涂抹,等待一段时间让黏合剂充分干燥固化。

注意事项:在使用纺织品黏合剂时,需要注意以下几点,要选择合适的黏合剂类型和规格,根据不同的材质和用途选择合适的黏合剂,要注意使用环境温度和湿度,避免在高温、潮湿环境下使用,使用过程中要注意安全,避免接触皮肤和眼睛,要按照产品说明书上的使用方法进行操作,避免误用或滥用。

黏合剂的发展趋势与前景

随着科技的不断发展,纺织品黏合剂也在不断发展和创新,纺织品黏合剂将会更加环保、高效、耐用,随着人们对纺织品品质和性能的要求不断提高,纺织品黏合剂也将更加注重产品的美观、舒适和耐用性等方面,随着智能制造和数字化制造的不断发展,纺织品黏合剂也将更加智能化和自动化,提高生产效率和产品质量。

纺织品黏合剂是一种重要的化学物质或材料,广泛应用于各种领域,它们具有多种种类和特性,可以根据不同的材质和用途选择合适的黏合剂,在使用纺织品黏合剂时,需要注意使用方法和注意事项,遵循正确的操作步骤,随着科技的不断发展和创新,纺织品黏合剂也将不断发展和完善,提高产品的品质和性能。

Articles related to the knowledge points of this article:

Exploring the World of Weijer Textiles:A Journey into Quality and Innovation

The Evolution and Impact of Shaoxing Yifeng Textiles

The 11th Floor of Xining Textiles:A Global Tapestry

Understanding Textile Fibre Testing:An In-Depth Analysis