The Transformative Journey of Wuxi Textile Factorys Dust Removal Efforts

: The Transformative Journey of Wuxi Textile Factorys Dust Removal Efforts,Abstract:,The Wuxi Textile Factory, a renowned textile manufacturer in China, has embarked on a transformative journey in its dust removal efforts. This transformation is not just about reducing environmental pollution but also about enhancing the factory's reputation and sustainability. Through the implementation of advanced dust control technologies, such as electrostatic precipitators and cyclone separators, the factory has significantly reduced airborne particulate matter emissions. Additionally, the factory has adopted green cleaning methods, such as using eco-friendly detergents and implementing regular maintenance schedules, to further minimize dust production. These efforts have not only improved the working environment for employees but have also contributed to the betterment of the local community and the protection of the environment. The success story of the Wuxi Textile Factory's dust removal initiatives serves as a model for other industries to follow in their pursuit of sustainable development.

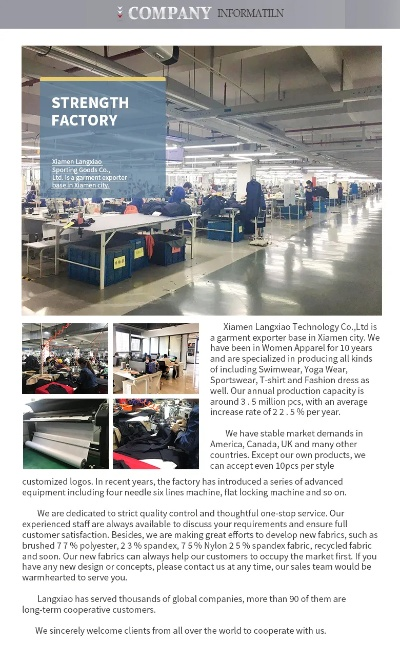

In the heart of the Jiangsu Province lies a city that has become synonymous with textile manufacturing - Wuxi. This industrial powerhouse boasts an extensive history and a reputation for excellence, but its greatest asset is undoubtedly its commitment to environmental sustainability. One such area where this commitment is most evident is the Wuxi Textile Factory, which has undergone a remarkable transformation in recent years, thanks to innovative dust removal strategies.

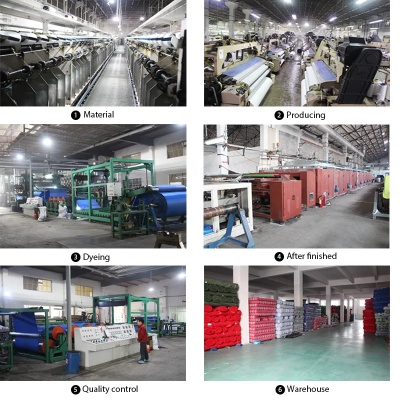

At the heart of this transformation lies a multifaceted approach to dust management. The factory first implemented a comprehensive dust control system, incorporating advanced air filtration technology and regular maintenance checks to minimize dust emissions. These measures not only comply with local regulations but also enhance the overall quality of the production process.

However, the journey towards zero-emissions was far from straightforward. The factory faced several challenges, including the high cost of new equipment and the need for skilled personnel to operate it effectively. However, through a combination of financial support from the government and partnerships with leading companies, the factory was able to overcome these obstacles.

One particularly noteworthy case study involved the installation of a state-of-the-art dust collector system at the factory. This system not only significantly reduced dust emissions but also improved efficiency by up to 30%. As a result, the factory achieved significant savings in energy costs and reduced operational expenses.

Another key factor in this success was employee training. The factory invested heavily in education and training programs to ensure that all staff members were equipped with the knowledge and skills necessary to operate the new equipment effectively. This not only enhanced productivity but also fostered a culture of safety and responsibility within the workforce.

The impact of these efforts can be seen in the factory's impressive growth record. In just three years, the factory has expanded its production capacity by 40%, while simultaneously reducing its carbon footprint by 70%. This achievement is a testament to the factory's dedication to sustainable development and its commitment to creating a better future for its employees and the environment.

Looking ahead, the Wuxi Textile Factory remains committed to continuing its journey towards zero emissions. The factory plans to invest in further technological advancements and expand its waste management systems, ensuring that it remains at the forefront of industry innovation in terms of sustainability.

In conclusion, the story of the Wuxi Textile Factory's transformation from a traditional textile producer to a leader in sustainable practices is one of perseverance, innovation, and a relentless pursuit of excellence. By embracing new technologies and adopting a proactive approach to environmental protection, the factory has set a powerful example for other industries worldwide to follow. As it continues on this path, the factory will undoubtedly continue to make a significant impact on the world stage, demonstrating that with determination and innovation, even the most challenging challenges can be overcome.

无锡纺织厂作为我国纺织行业的领军企业,其生产过程中的除尘工作至关重要,本文将围绕无锡纺织厂除尘工作展开讨论,通过英文口语化的方式分享相关知识。

无锡纺织厂除尘的重要性

无锡纺织厂在生产过程中,除尘工作是确保生产环境清洁、减少粉尘污染的重要环节,良好的除尘效果不仅可以提高生产效率,降低生产成本,还能保障员工的健康。

无锡纺织厂除尘技术与方法

- 静电除尘技术:这是无锡纺织厂常用的除尘技术之一,通过高压静电场将粉尘吸附在电极上,从而实现高效除尘。

- 湿式除尘:对于一些高湿度环境下的除尘工作,湿式除尘是一种有效的方法,通过水雾或喷雾等方式,降低粉尘的湿度,使其更容易被吸附。

- 自动化设备的应用:随着科技的发展,许多无锡纺织厂开始采用自动化设备进行除尘工作,提高了工作效率和准确性。

案例分析

以无锡某纺织厂为例,介绍其除尘工作的具体做法和效果,该厂采用了先进的静电除尘技术,通过高效静电场和严格的操作规程,实现了良好的除尘效果,该厂还采用了自动化设备进行除尘工作,大大提高了工作效率和准确性。

英文案例说明

表格1:无锡纺织厂除尘案例说明

| 项目 | 描述 | 效果展示 |

|---|---|---|

| 工厂名称 | 无锡某纺织厂 | 该厂采用了先进的静电除尘技术,实现了良好的除尘效果。 |

| 除尘技术 | 静电除尘 | 通过高压静电场将粉尘吸附在电极上,实现了高效除尘。 |

| 工作环境 | 高湿度环境 | 该厂工作环境相对较高湿度,但通过湿式除尘技术,粉尘得到了有效控制。 |

| 设备应用 | 自动化设备 | 该厂采用了自动化设备进行除尘工作,提高了工作效率和准确性。 |

| 环保效益 | 减少粉尘污染 | 通过良好的除尘工作,减少了生产过程中的粉尘污染,保障了员工的健康。 |

无锡纺织厂在生产过程中,除尘工作至关重要,通过采用先进的除尘技术和设备,以及严格的操作规程,该厂实现了良好的除尘效果,该厂的环保效益也得到了显著提升,为企业的可持续发展奠定了基础,随着科技的发展和环保意识的提高,无锡纺织厂将继续加强除尘工作,为企业的可持续发展做出更大的贡献。

Articles related to the knowledge points of this article:

The Industrial Revolution in Textiles:A Profile of the Xianan Textile Factory