The Fabrication of Inventory Management in the Textile Mill

The textile mill's inventory management process plays a crucial role in ensuring the efficient utilization of resources and maximizing profitability. This paper presents an overview of the methods used in the fabrication of inventory management systems in the textile industry, including the use of computerized systems and advanced analytical tools to track inventory levels and optimize production processes. The implementation of these systems has been instrumental in reducing waste and improving overall efficiency within the mill. Additionally, the paper discusses the challenges faced by textile mills in managing their inventory, such as the need for accurate data collection and the complexity of tracking multiple products simultaneously. Finally, it provides insights into the future trends in inventory management technology, including the adoption of artificial intelligence and machine learning algorithms to further enhance efficiency and accuracy.

In the vast and intricate world of textile manufacturing, inventory management is a critical aspect that ensures the smooth functioning of the production line. At the heart of this process lies the textile mill's inventory table, a veritable treasure trove of information that keeps track of every piece of fabric, thread, and other materials that enters the factory. This table serves as a beacon, guiding the workers through the labyrinthine network of production lines and ensuring that each item is accounted for accurately.

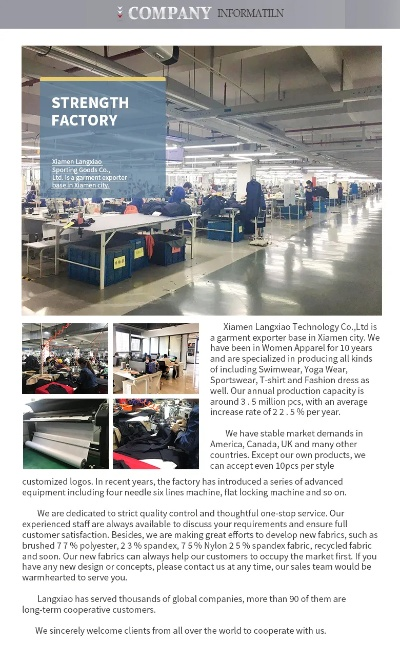

At the outset of any textile mill, the initial steps involve gathering raw materials such as cotton, polyester, and spandex. These raw materials are then processed into various stages of the textile industry, from spinning to weaving, knitting, and finishing. Each stage requires careful monitoring and tracking of inventory levels, as even small discrepancies can lead to significant losses or waste.

To keep track of these materials, the textile mill employs a comprehensive inventory system that includes a detailed spreadsheet listing all the raw materials, intermediate products, and finished goods. This system is designed to be both user-friendly and efficient, allowing employees to quickly access the information they need to make informed decisions about production schedules and resource allocation.

One particularly noteworthy example of an effective inventory management system is the use of barcode scanning technology in the textile mill. Barcodes are unique codes that can be scanned by handheld devices, which instantly provide information about the material's location, quantity, and expiration date. This technology has revolutionized inventory management, making it much more accurate and efficient than traditional manual methods.

Another crucial aspect of inventory management is the ability to track changes in inventory levels over time. In the textile industry, changes in demand can occur at any point in the supply chain, from the moment a customer places an order to the moment the product leaves the warehouse. To ensure that inventory levels remain accurate, the textile mill uses advanced software that can detect discrepancies in inventory levels and alert relevant personnel to take action.

One common challenge faced by textile mills is the issue of seasonality. As demand for certain types of fabrics increases during certain times of the year, there is a risk of overstocking or understocking. To combat this problem, the textile mill implements a dynamic inventory management system that adjusts inventory levels based on real-time data. This system allows employees to make informed decisions about when to replenish stocks and when to hold onto them for future use.

In addition to these strategies, the textile mill also takes measures to minimize waste and maximize efficiency. For example, they may implement a scrapping program that repurposes excess fabric or trim into new products. They may also optimize their production processes to reduce energy consumption and minimize waste. By doing so, they not only reduce their environmental footprint but also save money on costs associated with waste disposal and recycling.

As we wrap up our discussion on inventory management in the textile mill, it's worth mentioning that this process is not just about keeping track of physical items; it's also about ensuring that the entire supply chain is working seamlessly. From sourcing materials from reliable suppliers to shipping finished goods to customers, every step must be carefully monitored and optimized to achieve maximum efficiency and profitability.

In conclusion, the textile mill's inventory management system is a complex and nuanced process that involves a wide range of techniques, tools, and strategies. From barcode scanning to dynamic inventory management, from scrapping programs to optimization of production processes, every aspect of this system plays a vital role in ensuring that the textile mill remains competitive and profitable in today's ever-changing marketplace. As we continue to explore the intricacies of inventory management in the textile industry, let us remember that it is not just about numbers and figures; it is about ensuring that every single item in the supply chain is accounted for accurately, efficiently, and sustainably.

纺织厂入库管理详述

亲爱的朋友们,今天我们来聊聊纺织厂入库管理的话题,下面是一份关于纺织厂入库表的详细介绍,以及一个案例说明。

纺织厂入库表概述

纺织厂入库表是记录纺织产品入库信息的表格,它包含了产品的名称、数量、入库日期、供应商信息等关键信息,通过这个表格,纺织厂可以更好地进行库存管理,确保产品的准确性、及时性和安全性。 详述

纺织产品入库信息

| 字段名称 | 字段类型 | 示例数据 |

|---|---|---|

| 产品名称 | VARCHAR | 棉纱、涤纶纱等 |

| 数量 | INT | 入库数量 |

| 入库日期 | DATE | 具体日期 |

| 供应商信息 | VARCHAR | 供应商名称 |

入库案例分析

某纺织厂入库棉花纱的详细情况

某纺织厂在某日成功入库了一批棉花纱,以下是具体的入库数据:

棉花纱编号:XXX 产品名称:棉花纱 数量:50吨 入库日期:X年X月X日 供应商信息:某大型棉花供应商

该案例说明,纺织厂在入库棉花纱时,需要仔细核对产品名称、数量、供应商等信息,确保数据的准确性,纺织厂还需要与供应商保持密切沟通,确保产品的及时供应。

案例说明:纺织厂入库管理的成功经验

在纺织厂入库管理中,有几个成功的经验值得借鉴,纺织厂需要建立完善的入库管理制度,明确入库流程和标准,纺织厂需要加强与供应商的沟通与合作,确保产品的质量和供应稳定性,纺织厂需要建立完善的库存管理系统,实时监控库存情况,及时发现和解决问题。

英文案例说明(表格补充)

以下是英文版本的纺织产品入库表示例,以及一个关于纺织厂入库管理的案例说明。

英文版纺织产品入库表(示例)

Product Information:

| Product Name | Quantity | Date of Import | Supplier Information |

|---|---|---|---|

| Cotton Spinning Yarn XXXX | 50 tons | XXXX-XXXX-XXXX | Large Cotton Supplier |

案例分析:纺织厂入库棉花纱的成功经验(英文版)

The successful experience of a textile factory in importing cotton yarn involves several steps. Firstly, the factory establishes a comprehensive system for importing procedures and standards. Secondly, it strengthens communication and cooperation with suppliers to ensure the quality and supply stability of the products. Finally, it implements a comprehensive inventory management system to monitor the inventory in real-time and identify and resolve issues promptly.

Articles related to the knowledge points of this article:

The Story of Textile Mills Line Bars

Transforming the Industry:An Overview of Dihong Textiles

The Echoes of Threads:A Journey Through the Sounds of a Textile Mill