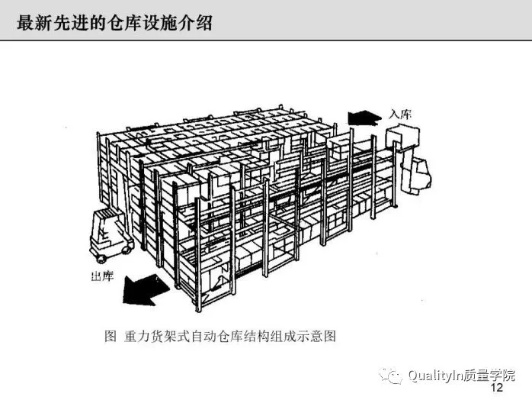

纺织品原料仓库安全设施的重要性与实施策略

: The Importance of Safety Measures in Textile Material Warehouses and Strategies for Implementation,Abstract:,The textile industry is a crucial sector that relies heavily on the safe storage and handling of raw materials. This paper discusses the importance of safety measures in textile material warehouses, highlighting the potential risks associated with improper storage conditions, such as fire hazards, electrical hazards, and chemical spills. It also explores the strategies that can be implemented to enhance safety measures, including regular inspections, proper training programs for employees, and the use of advanced technology to monitor warehouse activities. The paper concludes by emphasizing the need for continuous improvement in safety measures to ensure the safety of workers and protect the environment.

Introduction: The importance of ensuring the safety of textile raw material warehouses cannot be overstated. These facilities are often the first line of defense against potential hazards and accidents, which can have significant financial, environmental, and human impacts. In this article, we will discuss the key elements of a secure warehouse environment, including fire safety, electrical safety, and chemical handling. We will also provide an overview of some successful implementation strategies for these essential safety measures, as well as highlight an example case study to further illustrate the importance of these practices.

Fire Safety: Fire safety is perhaps the most critical aspect of any warehouse operation. Proper fire prevention measures should be in place to minimize the risk of fire outbreaks. A table summarizing recommended fire safety measures is provided below:

| Fire Safety Measures | Description |

|---|---|

| Smoke Alarms | Install smoke detectors throughout the warehouse to alert staff and emergency responders in case of fire. |

| Fire Extinguishers | Keep fire extinguishers accessible and easily retrievable in each area of the warehouse. |

| Escape Planning | Have a clear escape plan in place for all employees to ensure they know where to go and how to exit the building quickly during an emergency. |

| Ventilation System | Ensure proper ventilation systems are installed to prevent buildup of toxic fumes or gases that could lead to fires. |

| Electrical Safety | Regularly inspect electrical outlets, wiring, and equipment for signs of wear and tear or damage that could lead to a fire. |

Electrical Safety: Electrical safety is another crucial aspect of warehouse operations. It involves ensuring that electrical equipment and wiring are properly maintained and operated safely. Here's a table summarizing recommended electrical safety measures:

| Electrical Safety Measures | Description |

|---|---|

| Electrical Fault Identification | Conduct regular inspections to identify any potential faults or malfunctions in electrical equipment. |

| Electrical Maintenance | Schedule regular maintenance checks for electrical systems to ensure they are functioning correctly and safely. |

| Power Outage Prevention | Implement a power outage prevention system to minimize downtime due to power failures. |

| Ground Fault Circuit Interrupter (GFCI) | Install ground fault circuit interrupters in areas prone to electrical hazards to prevent electrocution. |

Chemical Handling: Chemical handling requires special attention to avoid exposure to harmful chemicals. Here's a table summarizing recommended chemical handling measures:

| Chemical Handling Measures | Description |

|---|---|

| Chemical Hazard Notification | Establish a protocol for notifying employees about the presence of hazardous chemicals. |

| Personal Protective Equipment (PPE) | Provide appropriate PPE such as gloves, masks, and goggles for handling chemicals. |

| Chemical Storage Rooms | Designate specific areas for storing chemicals that are classified by their hazard levels. |

| Chemical Disposal | Have a designated method for safely disposing of chemicals that are no longer needed or have been used up. |

Implementation Strategies: To ensure the effectiveness of these safety measures, it's important to implement them consistently and with a focus on training and education. Here are some examples of successful implementation strategies:

- Regular Training Programs: Conduct regular training sessions for employees on fire safety, electrical safety, and chemical handling procedures to reinforce best practices.

- Regular Inspections: Perform routine inspections of the warehouse to identify any potential hazards or areas for improvement.

- Emergency Response Plan: Develop an effective emergency response plan that outlines what to do in case of a fire, electrical issue, or chemical spill.

- Employee Engagement: Foster a culture of safety awareness among employees by encouraging open communication and reporting any issues they may encounter.

- Incentives for Safety: Offer incentives for employees who participate in safety training or demonstrate good safety habits to encourage continued commitment to safety.

Example Case Study: One example of a successful implementation strategy is the case of a textile manufacturer in New York City. The company had a history of fire incidents at its textile raw material warehouse, leading to significant losses and reputational damage. To address this issue, the company implemented comprehensive fire safety measures, including installing smoke alarms, fire extinguishers, and emergency escape plans. Additionally, the company conducted regular training sessions for employees on fire safety procedures and encouraged them to report any suspicious activities. As a result, there were no more fire incidents at the warehouse, and the company was able to rebuild its reputation and regain customers trust. This case highlights the importance of implementing effective safety measures and regularly reviewing and updating them to ensure ongoing compliance and prevent future incidents.

随着纺织业的快速发展,纺织品原料仓库的安全问题日益受到重视,为了确保原料仓库的稳定运行和人员安全,必须加强安全设施的建设和管理,本篇文章将围绕纺织品原料仓库安全设施展开讨论,并提供相关案例分析。

纺织品原料仓库安全设施概述

防火设施

在纺织品原料仓库中,防火设施是必不可少的,仓库应设置完善的消防系统,包括自动喷淋系统、灭火器等,应定期进行消防演练,提高员工对火灾的应对能力。

防泄漏设施

防泄漏设施包括防尘网、防潮柜等,防尘网可以有效防止原料在存储过程中产生的粉尘扩散,而防潮柜则可以保持仓库内湿度适宜,防止原料受潮。

监控设施

监控设施包括视频监控系统、温度和湿度监测设备等,视频监控系统可以实时监控仓库内的环境状况,及时发现和处理安全隐患,温度和湿度监测设备可以实时监测仓库内的温度和湿度变化,确保仓库环境的适宜性。

案例分析

某纺织品原料仓库安全设施建设实例

某纺织品原料仓库采用了先进的防火设施和防泄漏设施,确保了仓库的安全运行,该仓库配备了自动喷淋系统、灭火器等消防设备,并定期进行消防演练,该仓库还安装了防尘网和防潮柜等防泄漏设施,有效防止了原料的泄漏和粉尘扩散,该仓库还配备了视频监控系统和温度湿度监测设备,实时监控仓库内的环境状况,及时发现和处理安全隐患。

纺织品原料仓库安全设施改进措施

为了提高纺织品原料仓库的安全水平,该地区的一些纺织品原料仓库进行了安全设施的改进措施,增加了烟雾报警器等安全设备,提高了火灾应对能力;加强了仓库通风系统的建设,确保了仓库环境的适宜性;定期对员工进行安全培训,提高了员工的安全意识和应对能力。

英文表格补充说明

以下为英文表格补充说明:

纺织品原料仓库安全设施清单

| 安全设施类型 | 描述 | 示例配置 |

|---|---|---|

| 防火设施 | 自动喷淋系统、灭火器等 | 配备齐全,定期检查和维护 |

| 防泄漏设施 | 防尘网、防潮柜等 | 根据实际需求进行配置和更新 |

| 监控设施 | 视频监控系统 | 配备高清摄像头和存储设备 |

| 安全监控记录 | 实时监控记录、报警记录等 | 记录设备运行状态和异常情况 |

纺织品原料仓库的安全设施建设和管理对于保障人员安全和确保仓库稳定运行具有重要意义,在建设过程中,应注重防火、防泄漏、监控等方面的措施,同时应结合实际情况进行配置和更新,还应定期进行安全培训和演练,提高员工的安全意识和应对能力,通过加强安全设施的建设和管理,可以有效预防和减少纺织品原料仓库安全事故的发生,保障人员的生命财产安全。

Articles related to the knowledge points of this article: