The Duties and Responsibilities of a Textiles Production Manager

A Textiles Production Manager is responsible for overseeing the entire textile production process, from raw material procurement to finished product assembly. This role involves managing and coordinating the efforts of a team of employees, ensuring that the production schedule is met on-time and within budget. The manager must also be knowledgeable about the latest industry trends and technologies, as well as the quality standards required for each type of textile product. In addition, they are expected to have excellent communication skills, both verbal and written, in order to effectively communicate with suppliers, customers, and other departments within the company. Ultimately, the goal of this role is to ensure that the company's products meet or exceed customer expectations, while also maintaining profitability and sustainability practices.

In the textile industry, the role of a production manager is crucial as they oversee the entire production process from raw materials to finished products. A successful textiles production manager must have a deep understanding of the industry, excellent communication skills, strong organizational and leadership abilities, and the ability to manage multiple tasks simultaneously. In this article, we will discuss the duties and responsibilities of a textiles production manager in detail.

-

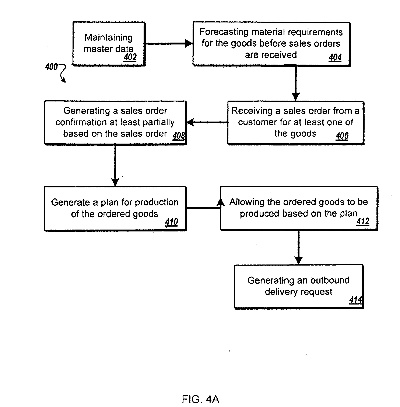

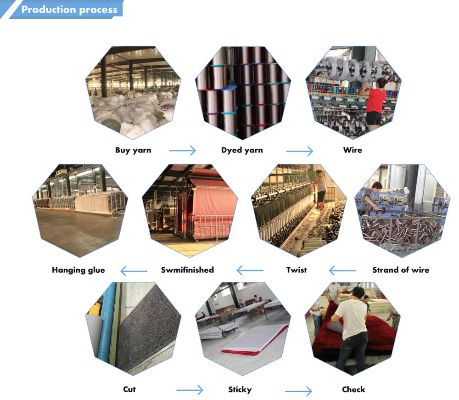

Planning and Scheduling The first duty of a textiles production manager is to plan and schedule the production process. This includes determining the production targets, identifying the required raw materials, allocating resources, and setting up production schedules. For example, if a company plans to produce 10,000 units of a specific fabric, the production manager needs to determine how many machines are needed, which raw materials are required, and when they should be delivered.

-

Quality Control Quality control is another critical responsibility of a textiles production manager. They need to ensure that all products meet the required standards and quality requirements. This includes inspecting the finished products, analyzing the data from the production process, and making necessary adjustments to improve the quality of the products. For instance, if the production manager discovers that a certain color is not consistent across the batch, they may need to adjust the dyeing process or change the recipe.

-

Supplier Management The production manager also has a significant role in managing suppliers. They need to establish good working relationships with suppliers and ensure that they provide high-quality raw materials on time. Additionally, they need to monitor supplier performance to ensure that they meet the production requirements and deadlines. For example, if a supplier fails to deliver the required quantity of yarn on time, the production manager may need to negotiate with them to resolve the issue.

-

Employee Training and Development The production manager needs to provide training and development opportunities for their employees to improve their skills and work efficiency. This includes providing technical training, workshops, and seminars related to new technologies and processes. For example, if a new machine is introduced into the production line, the production manager may need to provide training to employees on how to operate the new machine effectively.

-

Risk Management Risk management is another important responsibility of a textiles production manager. They need to identify potential risks associated with the production process and take appropriate measures to mitigate them. For example, if there is a risk of fire or explosion during the production process, the production manager needs to implement safety measures and regulations to prevent accidents.

-

Financial Management Financial management is also an essential aspect of a textiles production manager's job. They need to monitor the financial performance of the company and ensure that the production process meets the budget requirements. This includes tracking expenses, calculating profit margins, and making necessary adjustments to the production process to optimize costs. For example, if the production manager discovers that a certain material is costing more than expected, they may need to investigate why and make necessary changes to reduce costs.

-

Customer Relationship Management Building strong customer relationships is crucial for success in the textiles industry. The production manager needs to maintain regular communication with customers to understand their needs and preferences. This includes responding to customer feedback, addressing any issues or complaints, and providing recommendations for future products. For example, if a customer requests a custom design for a product, the production manager may need to collaborate with designers and engineers to develop a unique design that meets the customer's requirements.

-

Legal Compliance Finally, it is important for a textiles production manager to ensure that the company complies with all relevant laws and regulations. This includes ensuring that the production process does not violate environmental protection laws, labor laws, or other relevant regulations. For example, if a company produces clothing made from synthetic materials, they need to comply with regulations related to animal testing and labeling.

In conclusion, a textiles production manager plays a crucial role in ensuring the success of the company's production process. They need to have a deep understanding of the industry, excellent communication skills, strong organizational and leadership abilities, and the ability to manage multiple tasks simultaneously. By following these duties and responsibilities, a textiles production manager can help their company achieve its goals and meet the demands of customers and stakeholders.

纺织品生产经理职责概述

纺织品生产经理是负责纺织品生产过程中的全面管理,确保产品质量、生产效率以及成本控制的关键角色,其主要职责包括但不限于以下几个方面:

- 制定并执行纺织品生产计划,确保生产活动与公司的整体战略目标保持一致。

- 负责纺织品原材料采购、生产设备维护和更新,确保生产流程的稳定性和效率。

- 监控生产过程中的质量、成本和交货期等关键指标,确保满足客户需求和公司标准。

- 协调内部各部门之间的沟通与合作,确保生产过程中的顺畅运行。

- 负责新产品的研发和生产过程优化,提高生产效率和产品质量。

- 参与行业交流与合作,了解行业动态和趋势,为公司发展提供决策支持。

具体职责详解

(一)原材料采购与供应商管理

- 负责与供应商进行谈判,确保原材料的质量和供应稳定性。

- 监控原材料市场价格变化,及时调整采购策略,降低采购成本。

- 建立和维护与供应商的良好合作关系,确保原材料供应的及时性和稳定性。

(二)生产设备维护与更新

- 负责制定设备维护和更新的计划,确保生产设备的正常运行。

- 定期对生产设备进行检测和维护,确保设备性能稳定和安全。

- 及时处理设备故障,保证生产线的连续性和稳定性。

(三)质量控制与检验

- 负责制定并执行纺织品质量标准和质量检验流程。

- 对生产过程中的质量数据进行监控和分析,及时发现并解决质量问题。

- 参与质量改进项目,提高产品质量和客户满意度。

(四)生产效率与成本控制

- 分析生产过程中的瓶颈和问题,提出改进措施和建议。

- 优化生产流程,提高生产效率。

- 监控生产成本,控制生产成本在预算范围内。

(五)团队协作与沟通

- 与生产部门、技术部门、销售部门等内部各部门进行沟通与合作。

- 定期组织内部培训和技术交流活动,提高团队整体素质。

- 参与行业交流与合作活动,了解行业动态和趋势,为公司发展提供决策支持。

案例说明

为了更好地说明纺织品生产经理的具体职责和工作流程,我们可以结合一个具体的案例进行分析,某纺织公司在纺织品生产过程中遇到了原材料供应不稳定的问题,导致生产进度受阻,为了解决这个问题,纺织品生产经理采取了以下措施:

- 与供应商进行谈判,确保原材料的质量和供应稳定性,加强与供应商的合作力度,建立稳定的合作关系。

- 对生产设备进行定期检测和维护,确保设备性能稳定和安全,引入先进的生产设备和技术,提高生产效率和质量。

- 加强质量控制和检验力度,制定更加严格的质量标准和质量检验流程,组织内部培训和技术交流活动,提高团队整体素质,通过这些措施的实施,该纺织公司的生产进度得到了有效恢复,产品质量也得到了显著提高。

英文表格补充说明(可选)

以下是一个英文表格来补充说明纺织品生产经理的具体职责和工作流程:

表格1:纺织品生产经理职责概述表格补充说明(英文版) | 具体描述 | 相关数据支持 | | --- | --- | --- | | 制定并执行纺织品生产计划 | 负责制定年度、季度和月度生产计划,确保与公司的整体战略目标保持一致 | 生产数据、市场趋势分析等 | | 原材料采购与供应商管理 | 与供应商进行谈判,确保原材料的质量和供应稳定性 | 供应商评价报告、采购成本分析等 | | 生产设备维护与更新 | 负责制定设备维护和更新的计划,确保设备性能稳定和安全 | 设备维护历史数据、设备性能测试报告等 | | 质量监控与检验 | 负责制定并执行纺织品质量标准和质量检验流程 | 质量检测数据、质量改进项目记录等 | | 生产效率与成本控制 | 分析生产过程中的瓶颈和问题,提出改进措施和建议 | 生产效率提升数据、生产成本分析等 | | 团队协作与沟通 | 与各部门进行沟通与合作,确保生产过程的顺畅运行 | 沟通记录、内部培训活动照片等 | | 工作流程示例:与供应商合作洽谈 | 与多家供应商进行洽谈,确保原材料的质量和供应稳定性 | 相关采购合同、供应商评价报告等 | | 工作流程示例:设备检测和维护计划制定 | 对关键设备进行定期检测和维护计划制定,确保设备性能稳定和安全 | 设备检测和维护历史数据、维护记录等 | | 工作流程示例:质量控制与检验实施 | 对纺织品进行质量检测和质量改进项目实施,确保产品质量符合标准 | 质量检测数据、质量改进项目记录等 |

通过这个表格的补充说明,可以更好地展示纺织品生产经理的具体职责和工作流程,为相关人员提供参考。

Articles related to the knowledge points of this article:

A Profile of PJSH Textiles The Fabric of Modern Elegance

Patterns on Windows:A Visual Journey through Textile Design

The Fabric of Luxury:An In-depth Look at Shangbo Hotel Textiles

Understanding Color in Textiles:A Comprehensive Guide

Discover the Sweetheart Fabrics Store

Suzhou Xinying Textiles:Navigating the Global Fashion Industry