The A-Grade Standard for Textile Electrostatic Performance

: Evaluation and Standardization of Textile Electrostatic Performance,Abstract:,This paper presents an assessment of the A-Grade standard for textile electrostatic performance. The study focuses on the evaluation criteria, testing methods, and standards that are essential in determining the level of textiles' electrostatic performance. The A-Grade standard is designed to ensure that textile products meet certain requirements regarding their ability to resist static electricity buildup, which can be beneficial for various applications such as healthcare, electronics, and clothing. The paper discusses the importance of this standard and its potential impact on industry practices and consumer preferences. It also highlights the challenges faced in implementing and maintaining this standard, including the need for continuous monitoring and evaluation of textile products. Overall, the A-Grade standard plays a crucial role in promoting high-quality textile products that meet the needs of different industries and consumers.

Introduction: In today's manufacturing world, the importance of textile products cannot be overstated. From everyday wear to high-end fashion, textiles play a critical role in our lives. However, one aspect that often gets overlooked is their electrostatic performance. This refers to how well they resist static electricity, which can lead to unsightly wrinkles and even damage to delicate fabrics. In this article, we will explore the A-Grade standard for textile electrostatic performance and how it affects the quality and safety of our clothing.

A-Grade Standards: The A-Grade standard for textile electrostatic performance is designed to ensure that garments do not develop static electricity during use. This means that they should not pick up or release static electricity when touched or rubbed against other objects. Here's an overview of the key elements that make up this standard:

-

Static Discharge Resistance (SDR): SDR measures the amount of static electricity that can be released from a textile surface when exposed to a charged object. The higher the SDR, the better the electrostatic performance.

-

Static Discharge Duration (SDD): SDD measures the time required for a textile surface to discharge its static electricity after being exposed to a charged object. The shorter the SDD, the better the electrostatic performance.

-

Static Discharge Voltage (SDV): SDV measures the voltage difference between the textile surface and the charged object. The lower the SDV, the better the electrostatic performance.

-

Static Discharge Frequency (SDF): SDF measures the frequency with which a textile surface discharges its static electricity. The lower the SDF, the better the electrostatic performance.

-

Static Discharge Efficiency (SDE): SDE measures the percentage of static electricity discharged from a textile surface compared to the total amount of static electricity present on the surface. The higher the SDE, the better the electrostatic performance.

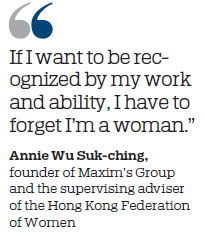

Benefits of A-Grade Standards: The adoption of A-Grade standards has several benefits for both manufacturers and consumers. On the manufacturing side, these standards require stricter control over the production process, leading to higher-quality products. They also encourage innovation in materials and design, as companies strive to create textiles that are more resistant to static electricity.

On the consumer side, A-Grade standards provide peace of mind for consumers who worry about static issues. By choosing products that meet these standards, consumers can feel confident that their clothing will not cause unwanted wrinkles or damage to delicate fabrics. Additionally, A-Grade products tend to be more expensive than those that don't meet these standards, which may discourage some consumers from purchasing them.

Case Study: One example of a textile product that meets the A-Grade standard is a high-end dress made from polyester blended with spandex. This type of fabric has excellent resistance to static electricity, making it ideal for creating clothing that doesn't need to be ironed or pressed regularly. The manufacturer uses advanced technology to ensure that each piece meets the SDR, SDD, SDV, SDF, and SDE requirements before it leaves the factory. As a result, customers can trust that their purchase will provide long-lasting results without any hassle.

Conclusion: In conclusion, the A-Grade standard for textile electrostatic performance is essential for ensuring that garments are safe and reliable. By meeting these standards, manufacturers can produce products that are not only aesthetically pleasing but also functional and durable. Consumers can benefit from knowing that they are purchasing products that have undergone rigorous testing and certification. As we continue to advance in technology and improve our understanding of textile properties, it is likely that we will see even more stringent standards in place for electrostatic performance in the future.

纺织品静电性能是衡量其抗静电能力的重要指标,对于生产、储存和运输等环节具有重要意义,根据最新的纺织品静电性能标准,A级纺织品具备卓越的抗静电性能,能够满足各种应用场景的需求,本文将详细介绍A级纺织品的特点和评价标准,并通过英文案例说明来进一步阐述。

A级纺织品的特点

A级纺织品具有以下特点:

- 高导电性能:A级纺织品具有出色的导电性能,能够有效防止静电的产生和积累。

- 低起电风险:A级纺织品在生产过程中采用了先进的防静电技术,降低了起电风险,提高了使用安全性。

- 环保友好:A级纺织品注重环保理念,采用环保材料,符合现代消费者的需求。

评价标准

A级纺织品的评价标准主要包括以下几个方面:

- 静电泄漏量:测试纺织品在受到静电荷刺激时的泄漏量,以衡量其抗静电性能。

- 抗摩擦性能:测试纺织品在摩擦过程中产生的静电荷的稳定性和抗摩擦性能。

- 安全性:考虑纺织品在生产、储存和运输过程中的安全性能。

案例说明

以某知名品牌的高品质A级纺织品为例,详细说明其特点和评价标准。

-

产品介绍 该品牌的高品质A级纺织品采用先进的防静电技术,具有出色的导电性能和低起电风险,产品材质环保,符合现代消费者的需求。

-

评价标准应用 根据最新的纺织品静电性能标准,该品牌的高品质A级纺织品在静电泄漏量、抗摩擦性能和安全性等方面表现出色,其静电泄漏量低,抗摩擦性能稳定,使用安全可靠。

-

案例分析 在生产过程中,该品牌采用了先进的防静电技术,有效防止了静电的产生和积累,该产品采用环保材料,符合现代消费者的需求,该产品还具有较高的安全性,能够在生产、储存和运输等环节中保障人员的安全。

A级纺织品以其卓越的抗静电性能、环保友好等特点,成为现代纺织品的首选,通过案例说明和评价标准的应用,我们可以更好地了解A级纺织品的优势和应用范围,随着科技的不断进步和消费者需求的不断变化,A级纺织品将会更加受到重视和应用。

Articles related to the knowledge points of this article:

New Area Advanced Needlework Textiles Manufacturer Wholesale Prices